Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

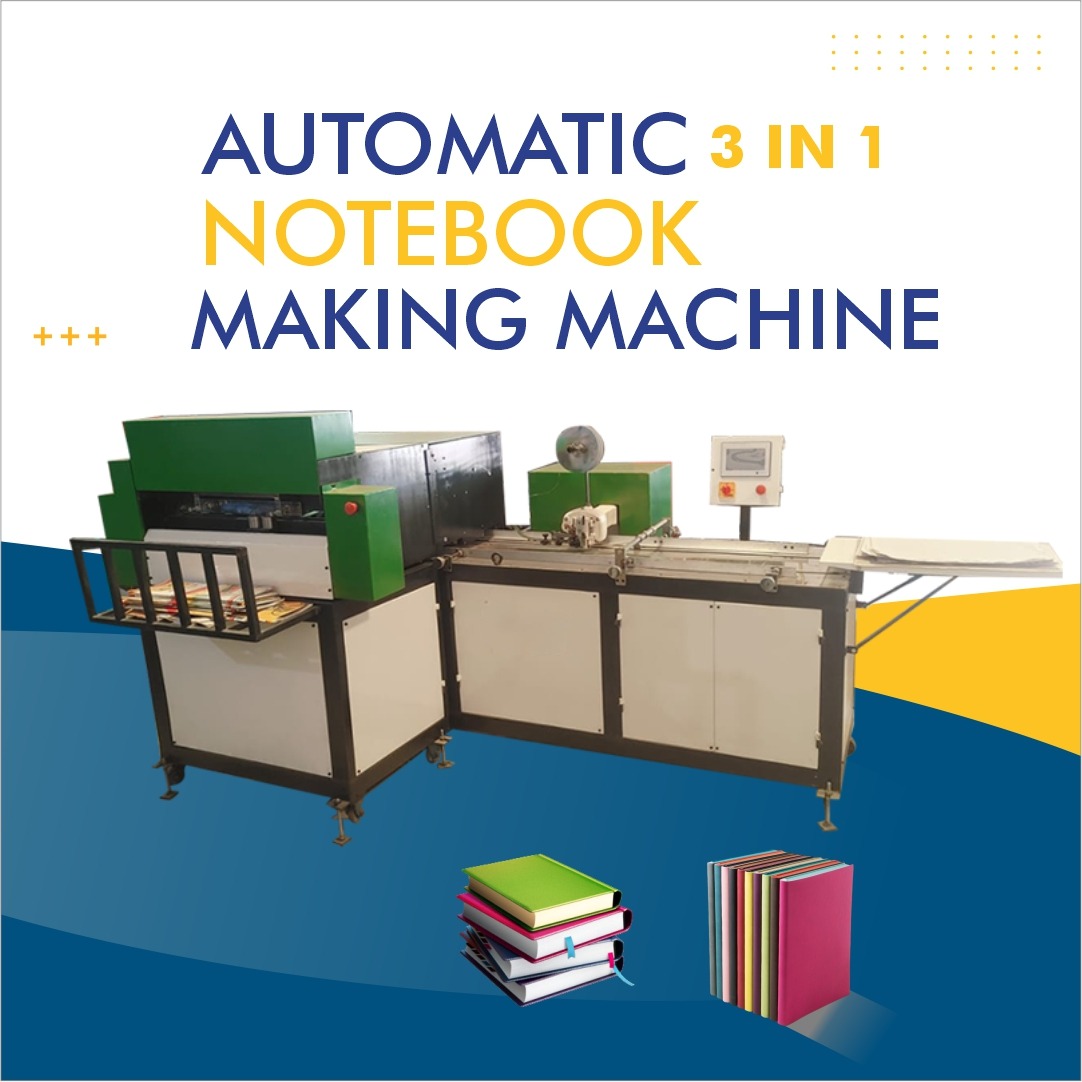

Notebook Making Machine | Ambikapur Chhattisgarh | Manufacturer & Exporter

Notebook Making Machine Ambikapur | Chhattisgarh

Ambikapur in the Indian state of Chhattisgarh is emerging as a hub for industrial equipment manufacturers. Among the key products manufactured here are notebook making machines. A notebook making machine is essential for producing school and office notebooks. If you are looking to buy or install a notebook making machine in Ambikapur, this guide gives you full insight into features, types, benefits, local suppliers, and how to choose the best equipment.

This article covers everything you need to know – from definitions and advantages to installation, maintenance, cost, and sourcing from a reputable notebook making machine manufacturer in Ambikapur, Chhattisgarh.

What is a Notebook Making Machine?

A notebook making machine is industrial equipment designed to automate or semi-automate the process of producing bound notebooks. It typically handles operations such as paper cutting, folding, stitching or gluing, binding, trimming, punching holes, and finishing. Modern machines can work continuously with high speed and precision, increasing production capacity while lowering labor costs.

Synonyms you may see used interchangeably include: notebook production machine, paper binding equipment, exercise book making machine, and school stationery production line.

Types of Notebook Making Machine

When sourcing a notebook making machine in Ambikapur, you will find various types based on automation, capacity, binding style, and level of customization. Some common types are:

-

Automatic Notebook Making Machine

Fully automated line which handles all steps from feeding paper sheets to final trimming. Ideal for high-volume production units that supply schools and retailers. -

Semi-Automatic Notebook Making Machine

Combines automated steps with manual input. Useful for mid-scale production units seeking balance between cost and automation. -

Manual or Table-Top Notebook Machine

Smaller footprint machines suitable for entrepreneurs or small stationery units that produce lower quantities. -

Customized Notebook Production Machine

These machines are tailored for special binding styles, cover lamination, or size variations required by customers. -

Corner-Cutting & Inner-Summary Machines

Additional modules or supplementary machines connected to the main binding line to perform trimming, corner rounding, punching etc.

Why Choose a Local Manufacturer in Ambikapur

Opting for a notebook making machine manufacturer located in Ambikapur or nearby region of Chhattisgarh has several advantages:

-

Proximity & Reduced Logistics Cost: Transporting heavy machinery over long distances adds cost. A local supplier reduces freight and handling charges.

-

After-Sales Service & Maintenance Support: Local manufacturer ensures quicker and easier access to repair, spare parts, and maintenance visits.

-

Customization & On-Site Installation: Engineers can visit your premises to install, calibrate, and test the notebook machine.

-

Cost-Effective Pricing: Without large shipping overheads, local vendors may offer more competitive pricing.

-

Compliance with Local Industrial Guidelines: Easier communication regarding electrical supply, safety, and local regulations.

When you search for “notebook machine Ambikapur” or “paper binding equipment Chhattisgarh”, you increase your chances of getting responsive local leads.

Key Features to Look For

When evaluating notebook making machines, whether automatic or semi-automatic, be sure to consider these critical specifications:

-

Production Speed: Measured in notebooks per hour or sheets per minute; high-speed automatic machines can produce several thousand per hour.

-

Sheet Size & Cover Size: The machine should support the dimensions you require — for instance A4, A5, or custom sizes used locally.

-

Binding Type: Stitching (wire or staple), glue binding, spiral binding or perfect binding depending on your product style.

-

Binding Thickness & Number of Pages: Maximum sheet capacity or thickness of the notebook spine you plan to produce.

-

Cutting & Trimming Accuracy: Quality of finish around edges, corner cuts, and trimming tolerances.

-

Material Handling: Capability to handle different paper grades, cover stock, lamination, or glossy finishes.

-

Automation Level & Controls: PLC control panels, touch-screen interface, safety sensors, and programmable settings.

-

Energy Consumption: Power rating, energy efficiency, and requirement for compressed air or auxiliary utilities.

-

Footprint & Floor Space: Physical dimensions of the machinery and required layout clearance.

-

Maintenance Requirements: Ease of access to wear parts, frequency of service intervals, and availability of spare parts near Ambikapur.

By comparing features against your projected output and investment budget, you can choose the notebook making machine that best fits your business.

Applications & Uses

Notebook making machines are used in many contexts:

-

School stationery production: producing exercise books, composition notebooks, drawing books for local schools in Chhattisgarh or for distributors.

-

Office stationery lines: corporate branding notebooks, promotional diaries, or customized notebooks for institutions.

-

Print-on-demand operations: small scale publishers or local print shops offering customized notebooks.

-

Export or Bulk Supply: manufacturers supplying larger volumes to booksellers or educational suppliers outside the district.

-

Training & Skill Development Centers: vocational training institutes teaching students how to operate machinery in paper-product manufacturing.

These varied uses make the choice of a high-performance notebook machine critical for quality, consistency, and competitiveness.

Cost Factors

When budgeting for a notebook making machine in Ambikapur, the following cost components should be considered:

-

Base Machine Price

Automatic equipments cost more than semi-automatic or manual machines. Prices vary with capacity, features, and customization. -

Installation & Commissioning Charges

Local vendor may charge fees for on-site installation, alignment, calibration, and training your staff. -

Electrical, Civil & Foundation Works

Heavy machinery may require reinforced floor foundation, wiring upgrades, or dedicated power lines. -

Shipping & Handling

Even with local supply, moving large machines within Chhattisgarh or from neighboring states incurs some logistics cost. -

Spare Parts & Warranty Packages

Ensure you have a warranty period and availability of consumables like blades, glues, staples, or wires. -

Operating Costs

Include electricity consumption, labor wages, maintenance downtime, and consumables over the life of the machine. -

Financing or Loan Costs

If you finance the printer through bank loans or industrial schemes, interest and overheads should be accounted for.

By estimating the total cost of ownership over 3 to 5 years, you can evaluate the return on investment (ROI) of your notebook making machine.

How to Choose the Right Manufacturer & Supplier

To ensure you partner with a suitable manufacturer near Ambikapur, follow these steps:

| Step | What to Do |

|---|---|

| 1. Research & Shortlisting | Search online directories for “notebook making machine manufacturer in Chhattisgarh” or “notebook making machine Ambikapur”. Review company websites, case-studies, and customer reviews. |

| 2. Request Technical Specifications | Ask for datasheets detailing speed, capacity, dimensions, power consumption, and binding options. |

| 3. Factory Visit | Schedule a visit to the manufacturer’s workshop. Inspect existing machines, see them in operation, and evaluate build quality. |

| 4. Site Assessment | Allow their engineer to inspect your production floor, power supply, floor strength, and space constraints before finalizing machine layout. |

| 5. Quality & Certifications | Check for quality standards or certifications applicable to industrial machinery in India. Ensure aftermarket support and service terms. |

| 6. Quotation Comparison | Compare quotations not just on upfront cost, but also on service contracts, spare parts availability, expected downtime, and maintenance support. |

| 7. Training & After-Sales Support | Ensure the supplier provides operator training, documentation, and timely maintenance visits. |

Using this methodical approach helps you select a reliable notebook making machine supplier near Ambikapur.

Maintenance & Safety Guidelines

Operating heavy stationery production equipment demands proper maintenance and safety protocols. Key guidelines include:

-

Maintain a preventive maintenance schedule, including lubrication, cleaning, alignment checks, and calibration at fixed intervals.

-

Train operators in proper handling, particularly in safety around cutting blades, moving parts, and electrical panels.

-

Keep critical spare parts inventory such as blades, binding wires or staples, glue nozzles, fuses, or sensors on-site for faster repair.

-

Ensure the electrical wiring, grounding, overload protection and safety guards are compliant with local industrial safety regulations.

-

Monitor machine performance parameters — speed consistency, binding strength tests, trimming accuracy — to detect wear and plan servicing before failures.

By following safety and maintenance best practices, you will prolong the lifespan of your notebook production machine and ensure consistent product quality.

Case Study / Use Scenario (Hypothetical)

Let us consider a mid-sized stationery manufacturer based in Ambikapur producing school exercise books for local schools and neighboring districts. They require a production capacity of 2,000 notebooks per hour in A4 size with stitched binding and trimmed edges.

They evaluate two options:

-

Semi-automatic notebook making machine: lower upfront cost, partially manual adjustments, requires 2 operators.

-

Automatic notebook making machine with PLC controls: higher price but minimal manual intervention, faster throughput, uniform quality.

After visiting two local manufacturers, they compare quotes, inspect prototype machines, and finally choose an automatic notebook production machine with capacity up to 2,500 notebooks per hour. They install it on a reinforced concrete floor, train staff over two days, and begin production.

Within a year, due to improved efficiency and lower labor cost per unit, they recoup the additional investment compared to a cheaper semi-automatic option.

Such results illustrate why careful planning, location-based supplier evaluation, and quality equipment matter.

Frequently Asked Questions (FAQ)

Q1. Can I upgrade a semi-automatic notebook machine to full automation later?

A: It depends on the model and the manufacturer. Some semi-automatic machines are modular and allow you to add modules like automatic feeder, automatic trimming or PLC interface later. Ask the manufacturer for upgrade options in Ambikapur.

Q2. What is the typical lead time for delivery and installation?

A: Lead time depends on machine complexity, customization and spare part availability. For a standard semi-automatic machine, it may be 4-8 weeks. Fully automatic machines with custom size features may take longer. Confirm with the manufacturer.

Q3. What power supply is needed?

A: Most notebook making machines operate on three-phase industrial power (e.g. 415V, 50 Hz), but specific models vary. Ensure voltage compatibility and confirm with your electrical contractor.

Q4. How long is the expected lifespan of such a machine?

A: With proper maintenance and usage, a notebook making machine can last 10 to 15 years or more. Consumable parts may be replaced periodically, while structural components are built for durability.

Q5. Are there government or MSME subsidies available for purchase of such equipment in Chhattisgarh?

A: There may be industrial equipment subsidies or state-level schemes applicable to small and medium enterprises (MSMEs). You should check with Chhattisgarh industry department or financial institutions for incentives related to machinery purchase.

Conclusion

If you are planning to set up or upgrade a notebook production line in Ambikapur, Chhattisgarh, selecting the right notebook making machine is critical. Ensure you choose a reputable local manufacturer, compare technical specs, assess total cost of ownership, and plan for installation, maintenance, and operator training.

By leveraging a machine that suits your production capacity, binding style, and available floor space, you can benefit from efficient production, reduced labor cost, and improved product quality. The right notebook making machine will become a strategic asset for your stationery business in Ambikapur and beyond.

To move forward, shortlist manufacturers in and around Ambikapur, request detailed proposals, visit their facility, evaluate live demonstrations, and then decide on a vendor who offers both performance and after-sales support.