Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

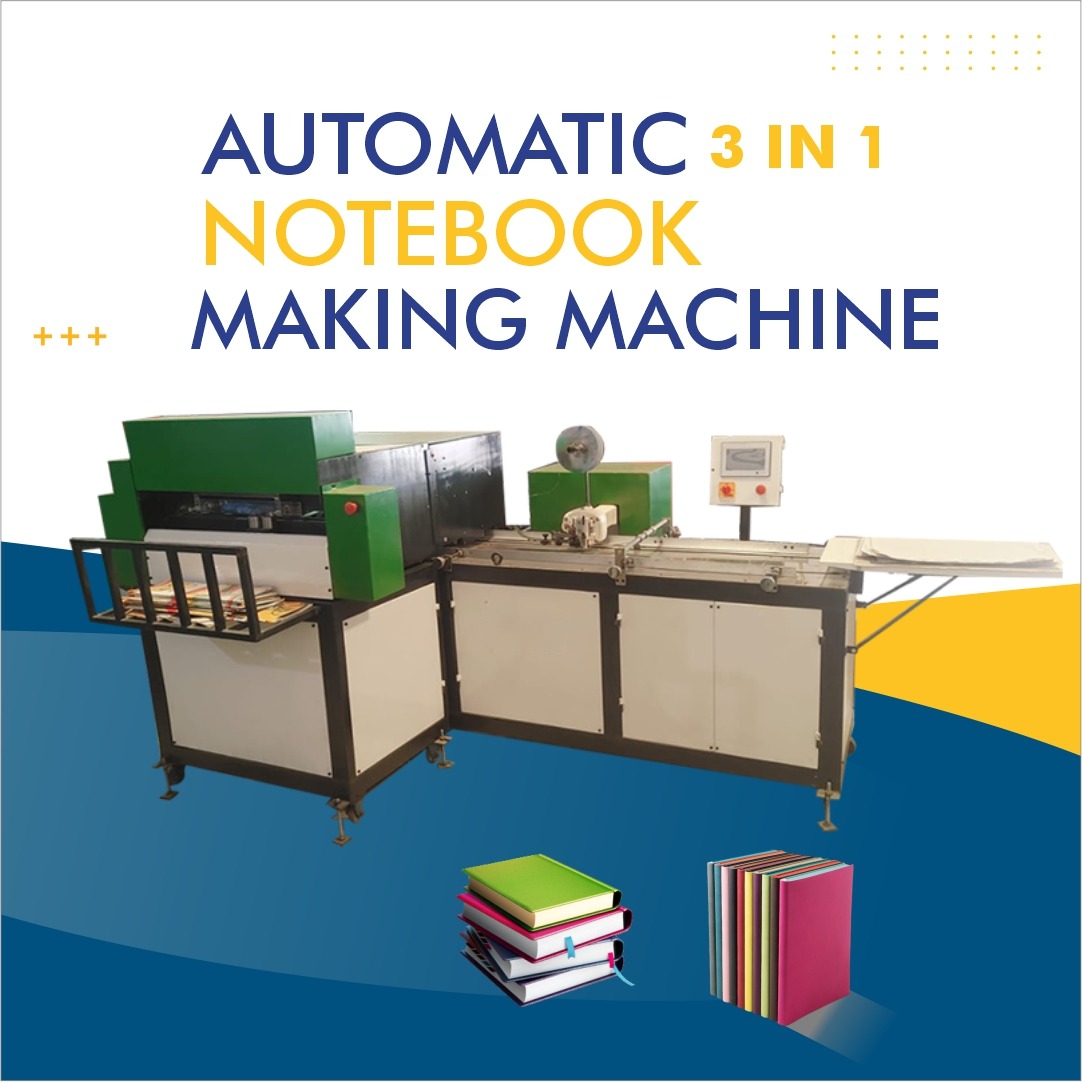

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Buy Notebook Making Machine in Akaltara – Chhattisgarh Manufacturer & Supplier

Notebook Making Machine in Akaltara | Chhattisgarh

Akaltara, Chhattisgarh is emerging as a hub for small and medium manufacturing enterprises. As demand for locally produced stationery grows, investing in the correct notebook making machine can transform operations. Whether you’re a startup stationery maker or an established manufacturer in Chhattisgarh, choosing the right equipment is crucial for quality, efficiency, and scalability.

A notebook manufacturing machine refers to any automated or semi-automated equipment that helps produce notebooks—from cutting paper sheets, binding, folding, to finishing. In Akaltara, businesses can benefit from on-site demonstration, service support, and locally accessible spare parts.

In this guide, we’ll walk you through:

-

Types of notebook making equipment available in Akaltara

-

Key features to evaluate

-

Benefits of local supply

-

Pricing and after-sales service

-

How to select the right paper binding equipment for your scale

We aim to help you make an informed choice for your stationery production line.

2. Why Choose a Local Supplier in Akaltara, Chhattisgarh

Proximity & Logistics

Having a supplier or manufacturer of notebook making machine base near Akaltara helps reduce shipping cost, delivery time, and allows for quicker installation and adjustment.

On-site Support & Maintenance

Local suppliers can visit your facility to inspect performance, adjust settings, and provide preventive maintenance for your industrial binding machine without long delays.

Regulatory Compliance & Customization

Machines supplied locally can be tailored to meet power supply standards, workshop space constraints, and local safety regulations. You may request modifications like metric sizing, paper format adjustments, or binding styles preferred in Chhattisgarh markets.

Cost Effectiveness

Importing machines from distant locations often includes high freight, customs, and delayed delivery. Local access reduces hidden costs and enables better budget planning for small entrepreneurs in Akaltara.

3. Types of Notebook Making Machines & Binding Equipment

Below are common categories and features to consider when choosing a notebook making machine or binding equipment:

A. Paper Cutting & Trimming Unit

The first stage in a notebook manufacturing machine setup is to cut large paper rolls or sheets into desired sizes. Choose a cutter with adjustable trimming, accuracy to ± 0.5 mm, and safety guards for operator protection.

B. Stitching / Staple Binding Machine

For staples binding notebooks, the staple binding machine attaches staples through folded sheets. Consider machine speed (books per minute), staple length compatibility, and whether the machine supports manual or automatic staple feeding.

C. Spiral Binding / Wire-O Binding Unit

If you wish to produce spiral notebooks, a spiral binding machine is essential. It bends wire or plastic spirals into pre-punched sheet stacks. Ensure the punching accuracy and wire twist tightness are adjustable.

D. Perfect Binding & Soft Cover Binding Equipment

Some notebook styles involve gluing the spine (perfect binding) or adding soft covers. A perfect binding machine presses adhesive along the spine and trims edges to give a professional finish.

E. Folding & Creasing Units

Folding machines or crease-fold units help fold sheets neatly, especially for multi-section notebooks or brochures integrated with your stationery line.

F. Paper Punching & Hole-Punching Station

Pre-punching holes at fixed intervals is necessary for spiral or wire binding. A punching station must align with margin tolerances and support various hole patterns.

G. Finishing & Laminating Machines

Though not strictly “notebook making machine”, finishing includes laminating covers, embossing logos or varnishing surfaces, which enhance perceived quality and durability.

4. Key Specifications to Compare

When evaluating notebook making machines or equipment, compare the following specifications:

| Specification | Why It Matters |

|---|---|

| Production Speed | Higher throughput reduces per-unit cost. Machines rated in notebooks per hour or bindings per minute matter for scaling. |

| Paper Size Range | Ability to handle different sheet sizes—e.g., A4, A5, custom formats for local schools. |

| Binding Style Flexibility | Whether it supports staple binding, spiral binding, glue binding, or hybrid styles. |

| Power Consumption & Electrical Compatibility | Voltage stability in Chhattisgarh and machine load should align with your workshop’s capacity. |

| Ease of Changeover | Switching from one size/design to another should not require excessive downtime or manual re-adjustment. |

| Material Compatibility | Thickness of paper, cover boards, wire gauge for spiral binding, staple gauge, type of glue. |

| Safety Features & Certifications | Emergency stops, guarding, CE- or BIS-equivalent compliance if applicable. |

| Durability & Maintenance Schedule | Wear-parts availability (e.g. blade, staple magazine, punch dies) and frequency of replacement. |

Each of these plays into your total cost of ownership, ROI, and smooth operation.

5. Benefits of Installing a Notebook Making Machine in Akaltara

Increased Output & Reduced Manual Labor

Automating cutting, binding, and finishing reduces labor costs and error rates. This increases consistent quality – especially important if you supply schools, colleges, or local stationery shops.

Competitive Advantage

If you can supply notebooks at lower cost, faster turnaround, or with additional binding styles (spiral, soft-cover, laminated covers), you’ll outperform competitors in nearby towns or districts.

Scalability

Once demand grows—say from local schools or government contracts—you can scale production by adding modules (extra binding heads, or upgrading from manual punch to automatic punching).

Local Market Reach

Producing notebooks on site in Akaltara helps you respond quickly to bulk orders from nearby areas like Korba, Raigarh, Janjgir, Bilaspur, and beyond. Reduced lead time can be a strong selling point.

Environmental & Quality Control

When production is local, you can ensure quality checks at each stage—paper cut alignment, binding strength, finishing consistency—and manage waste or scrap more efficiently.

6. Common Applications & Use Cases

-

Small stationery manufacturers launching their own branded notebook line.

-

School uniform store owners wanting to produce customized notebooks with school emblem.

-

Government or NGO tenders for distribution of writing pads in rural areas of Chhattisgarh.

-

Printing presses expanding services to include bound booklets, diaries, or spiral-bound notebooks.

-

Entrepreneurs building integrated production of printing, binding, and packaging.

In each case, having the right notebook manufacturing machine tailored to volume, binding type, and finishing specifications is vital.

7. Suggested Workflow for Implementation

-

Needs Assessment

-

Estimate monthly output (e.g. 10,000 notebooks).

-

Identify binding types you want to support (staple, spiral, glue).

-

Assess floor space, power supply, and ventilation.

-

-

Machine Selection & Quotation

-

Request quotes for all machinery modules (cutter, stapler-binding unit, puncher, folding unit).

-

Compare after-sales service commitments, spare-part availability, warranty terms.

-

-

Site Preparation

-

Ensure concrete-floored workshop with stable power.

-

Plan for dust extraction if cutting paper at high volume.

-

-

Installation & Training

-

Local supplier visits to install and calibrate.

-

Operator training to changeover sizes, perform maintenance.

-

-

Quality Control & Testing

-

Run trial batches. Check alignment, binding strength, finished appearance.

-

Adjust machine settings for margin tolerances or custom cover thickness.

-

-

Operations & Maintenance Schedule

-

Daily cleaning of cutting blades.

-

Regular lubrication and inspection of moving parts.

-

Maintain logbook for production numbers, downtime, and minor repairs.

-

-

Scale-Up & Optimization

-

After meeting initial target, plan upgrades – e.g. adding a faster punch-press machine or upgrading to dual-head binding press.

-

Review energy consumption and optimize layout for material flow.

-

8. Case Example (Hypothetical for Akaltara)

Suppose a stationery startup in Akaltara decides to invest in a spiral notebook machine + staple binding machine + cutter + punching unit. The estimated output is 5,000 spiral-bound notebooks per day during school season.

-

By automating punching and spiral insertion, labor cost reduces by about 40%.

-

Local supply of spare parts reduces downtime from average 2 days to under 12 hours.

-

Total payback period estimated at 9–12 months, given local sales to schools, tuition centers, and small retailers in nearby towns.

Over time, the same operator team can switch machine settings to produce different sizes (A5, A4) or cover styles (laminated, printed). The flexibility and proximity helps expand into other stationery lines.

9. Vendor Criteria & Checklist

When evaluating vendors or manufacturers in or near Akaltara, Chhattisgarh, you may ask:

-

Do you provide notebook making machine demonstrations on site?

-

What is the lead time and delivery schedule to Akaltara?

-

Can you customize dimensions, binding styles, or integrate with printing machines?

-

What warranty and preventive-maintenance contracts do you offer?

-

How do you price spare parts – blades, punch dies, staples or wire spiral coils?

-

Do you provide training for operators and maintenance staff?

-

What are the electrical & safety certifications?

Collect at least 2–3 vendor proposals and compare total cost of ownership (purchase price + installation + maintenance over 2-3 years).

10. Conclusion

Installing a quality notebook manufacturing machine in Akaltara, Chhattisgarh can empower stationery businesses to scale efficiently, maintain superior quality, and respond quickly to local demand. By choosing the right combination of cutter, binding machine, puncher, and finishing units—and by partnering with a supplier who understands regional requirements—you can build a reliable, profitable notebook production line.

Whether you aim to supply schools, retailers, or tenders in Chhattisgarh, investing in the correct paper binding equipment and maintaining it well will ensure long-term success. Contact local machine suppliers, assess your production goals, and plan your investment wisely — your next-generation notebook production facility could well start in Akaltara.