Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

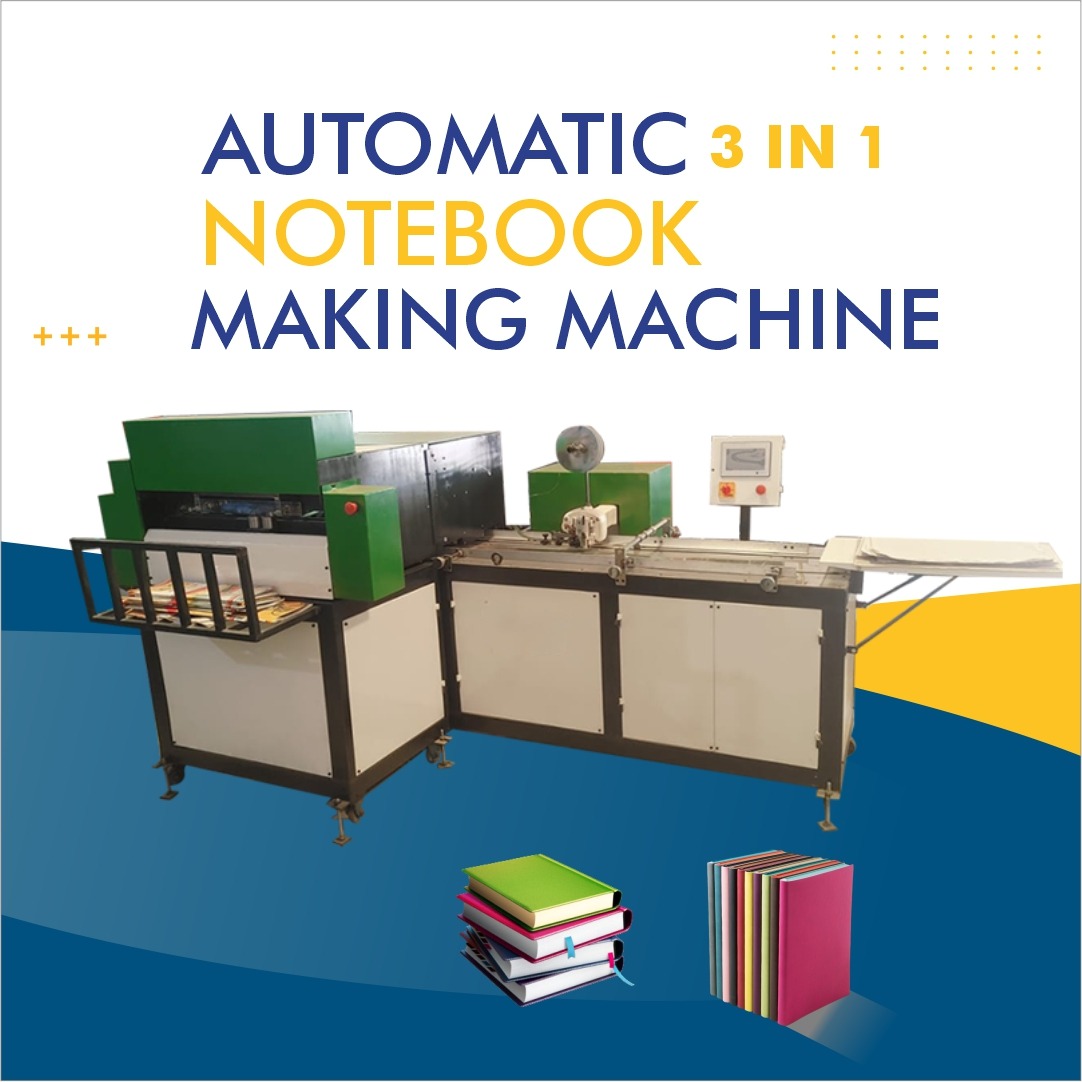

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Naubatpur Bihar – Reliable Manufacturer & Supplier

Notebook Making Machine in Naubatpur | Bihar

In the fast-growing market for stationery products, having a reliable notebook making machine is essential for manufacturers seeking efficiency, quality, and cost-effectiveness. If you’re located in or near Naubatpur, Bihar, you’ll want to source your machinery locally to reduce downtime, shipping costs, and ensure prompt maintenance. As a professional manufacturer and supplier, we specialize in high-performance equipment designed specifically for notebook production lines.

This article aims to guide you through everything you need to know about procuring a notebook making machine in Naubatpur, Bihar — from technical features to production capacity, maintenance, and how to choose the right machine for your business.

Why Choose a Local Manufacturer in Naubatpur, Bihar

-

Proximity & Reduced Logistics Cost

Choosing a notebook machine manufacturer located in or near Naubatpur means you benefit from lower freight charges and faster delivery times. Local support teams can visit your production site more quickly. -

Better After-Sales Support

Machines invariably require servicing or spare parts. With local presence, you can get timely maintenance and technical support for your notebook making machine. -

Understanding Market Needs

A supplier familiar with Bihar’s stationery industry understands your production volumes, raw-material quality (paper availability, binding materials), and regulatory requirements (e.g., paper recycling norms, local utility constraints). -

Customization & Flexibility

Local manufacturers are often more flexible — you can request custom specifications (batch size, sheet size, automation level) for your notebook production machine to suit your factory capacity.

Key Features to Look for in a Notebook Making Machine

When you’re evaluating options for a notebook making machine, these are the critical features you must consider:

-

Production Capacity: How many notebooks per hour or per shift the machine can deliver. Higher capacity can drive down per-unit cost.

-

Automation Level: Manual, semi-automatic, or fully automatic. A fully automatic notebook making machine may incorporate feeding, cutting, folding, stitching, binding and trimming in one line.

-

Cut Sizes & Formats: Compatibility with standard notebook dimensions used in India (e.g. A4, A5, 6-inch lines, 8/12/14/16 pages etc.)

-

Binding Method: Whether the machine uses staples (stitching), glue, sewn binding, or stitching plus adhesive binding.

-

Power Consumption & Energy Efficiency: Machines that are optimized for electricity use will lower operating costs, especially important in Bihar where power supply fluctuations and costs matter.

-

Durability & Build Quality: Robust frames (steel, cast iron), wear-resistant parts, reliable motors and safety features.

-

Ease of Maintenance: Availability of spare parts, ease of access for cleaning, lubrication, and quick repairs.

-

User Interface & Controls: PLC-based control panels, safety interlocks, emergency stops, and real-time production monitoring.

-

Cost & ROI (Return on Investment): Price of the machine vs expected increase in production capacity and reduction in labor cost.

These features will determine how well your investment in a notebook production machine will serve your business in the long term.

Common Types of Notebook Making Machines

Here are several types of machines you might consider:

-

Manual or Semi-Automatic Notebook Stitching Machine

These machines require human intervention at various points (paper feeding, guiding, pressing). They are more affordable and suitable for small-scale notebook producers in Naubatpur or nearby villages. -

Automatic Notebook Making Machine

Fully automatic systems that perform sequential operations — sheet cutting, folding, stitching, trimming, binding — all integrated into one production line. Ideal for mid- to large-scale manufacturers. -

Note Book Stitching Machine

Specifically focused on the binding or stitching portion. It may be used in combination with other machines (cutting, folding) to complete your production line. -

Paper Binding Machine / Book Binding Equipment

Used to bind multiple sheets into a finished notebook. These can include glue-binding units, trimming units, and may be integrated or stand-alone. -

Customized Notebook Production Line

For example, a tailored system that produces exercise books with printed covers, custom page counts, or special finishes. A bespoke line may include feeder, printer, cutting unit, folding unit, stitching unit, and finishing section.

Synonyms & Related Terms

Throughout this content, you’ll notice synonyms used for “notebook making machine” to improve search coverage:

-

note book making machine

-

notebook production machine

-

exercise book stitching machine

-

book binding equipment

-

paper binding machine

Each of these terms refers to similar or overlapping class of equipment, helping you discover the right machine whether you search by “book binding equipment in Bihar” or “automatic notebook making machine supplier.”

Choosing the Right Specification for Naubatpur-Based Production

When selecting a notebook making or stitching machine for use around Naubatpur, Bihar, here are local factors you should assess:

Paper Quality & Supply

Naubatpur and surrounding regions source paper from nearby mills. Confirm that the machine handles the GSM (grams per square meter) of paper you plan to use for inner sheets and covers. Your binding materials (staples or glue strips) should also meet local supply specs.

Power Conditions

Electric power supply may fluctuate. Choose a notebook manufacturing machine with overload protection, voltage stabilizers, or compatible with local voltage fluctuations. Efficient motors reduce breakdowns due to overload.

Labor Skills

If your workforce is semi-skilled, you may want a semi-automatic or user-friendly automatic machine with minimal manual adjustment. Training should be available by the manufacturer or supplier.

Space & Infrastructure

Confirm that your factory site near Naubatpur has adequate floor space, proper foundation, and structural strength for the size and weight of the notebook making machine. You may need civil foundation work and proper ventilation if the machine produces paper dust.

Regulatory & Safety Compliance

Ensure the machine meets safety norms (guarding, emergency stop, electrical safety) and any local BIS or industry-standard guidelines. Depending on local regulations in Bihar or district authority in Patna/Naubatpur area, compliance may be required for permits.

Cost & Finance

Based on your budget, choose between:

-

Entry-level manual or semi-automatic machine (lower capital cost, longer labor involvement)

-

Mid-range automatic notebook making machine (balanced cost vs throughput)

-

High-end large capacity production line (higher investment, faster payback if volumes are high)

Factor in shipping, installation, commissioning, and spare parts availability when calculating total investment cost.

Installation & Commissioning in Naubatpur, Bihar

Once you purchase your notebook making machine, the following steps are generally needed:

-

Site Preparation

Ensure floor level, foundations, and electrical wiring are in place. For heavy machinery, you may need concrete pads or vibration-dampening mounts. -

Machine Delivery & Unloading

Local transport to Naubatpur or nearby industrial zones. Unpacking, lifting equipment, alignment of machine according to leveling marks. -

Electrical & Mechanical Setup

Connect motors, control panel, safety devices, and test run without load. Align cutting blades, stitching heads, conveyor belts, and verify conveyor speeds. -

Trial Run & Calibration

Run sample notebooks to verify dimensions, folding quality, stitch integrity, trimming accuracy, and page count consistency. Adjust settings as required. -

Training

Manufacturer or technician from supplier trains your operators — feeding sheets, handling jams, replacing staples or binding supplies, maintenance tasks, safety protocol. -

Maintenance Schedule

A preventive maintenance plan (daily lubrication, weekly checks, quarterly servicing) helps maintain consistent output and extends the life of your notebook making machine.

Advantages of Owning a Notebook Making Machine in Naubatpur

-

Faster Turnaround: On-site production means you can fulfill orders quickly for schools, colleges, stationery shops in Patna district, Naubatpur block and neighbouring towns.

-

Competitive Pricing: By cutting transportation costs and assembling locally, you reduce the landed cost of notebooks.

-

Scalability: As your demand grows (e.g. school stationery orders in Bihar), you can expand production capacity by upgrading or adding additional units.

-

Quality Control: Direct oversight of production allows you to maintain binding strength, trimming accuracy, and appearance — which is essential for customer satisfaction.

Case Study (Hypothetical)

Suppose you operate a small-scale stationery unit near Naubatpur and want to upgrade from manual to semi-automatic production. You install a semi-automatic notebook stitching machine plus trimming and feeder attachments. Your output doubles from 500 notebooks per shift to 1,200 per shift. The capital cost is recovered within 8 months through increased orders. Your customers (local schools) appreciate consistent margin and on-time delivery. You later upgrade to a fully automatic notebook production machine to handle seasonal peaks (e.g. back-to-school period). This incremental investment strategy allows you to scale responsibly.

How to Get a Quote

If you’re interested in purchasing a notebook making machine in or near Naubatpur, Bihar, here’s what you should include in your inquiry:

-

Desired production capacity (notebooks per hour or per day)

-

Notebook size (A4, A5; page count; cover thickness)

-

Binding method (stitching/stapling or glue binding)

-

Level of automation (manual, semi-automatic, full-automatic)

-

Power supply details (voltage available, any stabilizer)

-

Site photos or measurements (floor space, ceiling height)

-

Budget range and expected delivery timeline

Send that information to a supplier or manufacturer. Ask for a site visit if needed. Verify warranty, maintenance service network, and spare-parts availability in Bihar or nearby.

Conclusion

If you're seeking a reliable notebook making machine in Naubatpur, Bihar, you have multiple options — manual, semi-automatic or fully automatic systems. Prioritize capacity, automation level, build quality, and local support. Work with a local manufacturer or supplier who understands the needs of stationery production in Bihar. Plan for installation, commissioning, training, and preventive maintenance. A well-selected note book making machine or note book stitching machine can significantly improve your productivity, quality, and competitiveness in the stationery industry.