Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

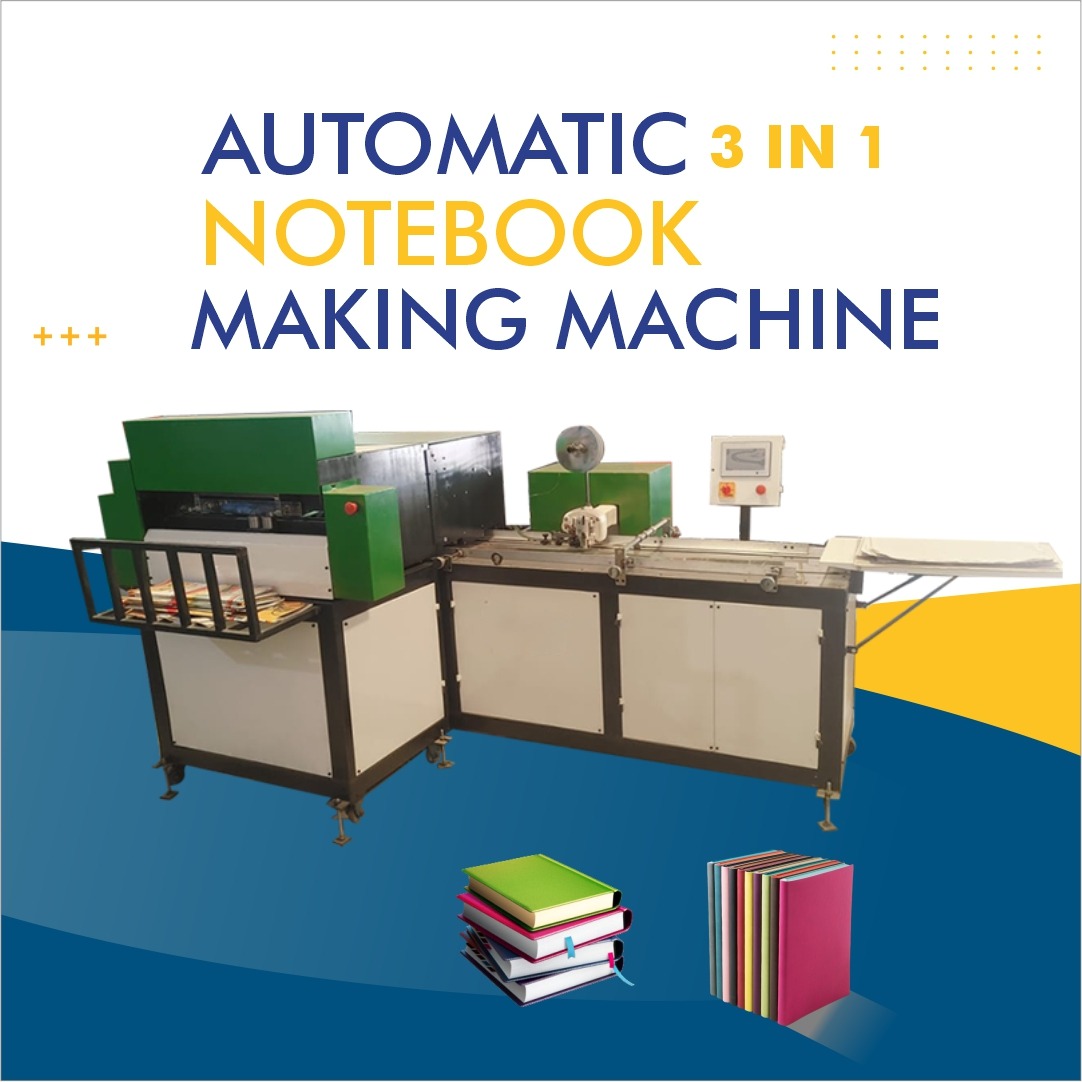

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier Mehsi Bihar – Best Notebook Machine in Bihar

Notebook Making Machine Supplier Mehsi Bihar

If you are seeking to set up a notebook manufacturing unit in Mehsi, Bihar, selecting the right notebook making machine is critical to the efficiency, quality, and profitability of your operation. From semi-automatic systems to fully automatic production lines, a well-chosen machine will help you produce notebooks with consistent binding, cutting accuracy, and finish. In this article, we explore the advantages of procuring a notebook making machine Mehsi-based supplier, the technical specifications you should evaluate, cost factors, maintenance, and why local sourcing in Bihar matters.

This content explores the types of machines, local vendor advantages, specifications, investment considerations, installation and after-sales support. By the end, you will know how to evaluate offers for a notebook machine manufacturer Bihar and make a reliable purchase decision.

Why Choose Local Supplier in Mehsi Bihar

-

Reduced Logistics Cost

Sourcing the notebook making machine from Mehsi or nearby towns in Bihar reduces transportation cost, import duty, and delays. Local delivery ensures quicker installation and lower shipping damages. -

Accessible Maintenance and Spare Parts

A local notebook machine supplier in Bihar can offer faster service response, and shorter waiting time for spare parts or repairs. This reduces machine downtime and improves your production continuity. -

Better Understanding of Regional Power, Labour, and Compliance Issues

Local vendors are more aware of utility supply patterns, labour skills in Mehsi, and regional regulatory compliance (electrical, safety certifications). That means installation and certification will be smoother. -

After-Sales Support & Training

A manufacturer or supplier near Mehsi can provide hands-on training for your staff, periodic maintenance visits, and preventive servicing strategies — all of which improve machine longevity. -

Economic Development & Local Networking

Working with a supplier in Bihar helps develop regional manufacturing ecosystems. You may benefit from state-level incentives or industrial policies designed to promote local manufacturing clusters.

Types of Notebook Making Machines

When you evaluate offers from a notebook making machine manufacturer Bihar, you will find several categories:

-

Manual or semi-automatic notebook making machines

These require manual feeding of sheets, manual alignment of binding wires, or manual operation of binding cycles. They are typically less expensive, simpler to operate, and suited for small-scale production. -

Automatic or fully-automatic notebook making machines

These integrate automatic sheet feeding, wire binding insertion, trimming and cover insertion in one streamlined line. They are ideal for mid- to large-scale production and deliver higher productivity and consistency. -

Modular production lines

Instead of one monolithic machine, you may procure modules (e.g. sheet cutting, die-cutting, binding insertion, trimming, packaging) which can be assembled or expanded in Mehsi. -

Specialized notebook machines

Some machines may offer additional features such as embossing, foil-stamping on covers, plastic spiral binding option, or customised sizing for school-notebooks or diaries.

Each type comes with advantages and trade-offs in terms of cost, maintenance, throughput, and ease of use.

Key Technical Specifications to Evaluate

When considering a notebook making machine Mehsi Bihar, you should examine the following parameters:

| Parameter | Why It Matters |

|---|---|

| Production Speed (notebooks per minute / per hour) | Higher throughput yields lower per-unit cost, but may require higher initial capital and more precision design. |

| Binding Type & Wire Capacity | Whether the machine uses wire-o binding, stitching, spiral or staple-binding; the wire diameter and pitch capacity define types of notebooks you can produce. |

| Paper Size & Thickness Support | Ability to handle A4, A5, or custom sizes and thickness ranges (e.g. 60-120 gsm for pages, thicker card-stock for cover). |

| Automation Level | Manual steps vs. automatic feeding, trimming, cover attachment, laminating etc. More automation means less labour cost but higher maintenance complexity. |

| Power Consumption & Motor Ratings | For energy cost estimation and to verify compatibility with Bihar electrical infrastructure. |

| Safety Features & Certifications | Emergency stop buttons, guarding, safety interlocks, compliance with local safety standards. |

| Footprint & Layout | Floor area required, ease of integration into your factory layout in Mehsi, space for feeding, output racks, operator access. |

| Serviceability & Spare Part Availability | Ease of replacement of critical components (motors, belts, sensors) by local vendor support. |

| Warranty & Training | Check whether the supplier offers onsite training in Mehsi, Bihar, and warranty support period. |

Ask prospective suppliers to provide datasheets, sample notebooks made on the machine, and performance demonstration.

Cost & Investment Considerations

Investing in a notebook making machine involves several cost elements:

-

Capital Cost

The base machine price depends on automation level, throughput capacity, and optional features. Local manufacturers in Mehsi may offer competitive pricing because of lower logistics and local input sourcing. -

Installation & Commissioning Cost

Moving, setting up the machine, calibration, and trial runs in Mehsi factory site — vendors often include this in proposal or may charge extra. -

Training & Labour Costs

If the operator staff are unskilled, training time will influence productivity initially. A local manufacturer can train your workforce onsite. -

Power & Utility Costs

Calculate monthly energy consumption based on rated power and expected run-hours. Factor in cooling, lighting, and any auxiliary systems such as vacuum pumps or compressors. -

Maintenance & Spare Parts Budget

Annual maintenance, spare-part replacement (cutting blades, binding wire feeders, feed rollers), and preventive servicing form part of operating cost. -

Depreciation & Pay-back Period

Estimate the number of notebooks you will sell per month, margin per piece, cost savings from efficiency, and compute time to recover investment. -

Financing Options & Incentives

Check whether Bihar Government or central government industrial schemes or subsidies are available for notebook manufacturing or machinery purchase near Mehsi.

Selecting the Right Vendor in Mehsi Bihar

To select a reliable notebook machine supplier or manufacturer in Bihar / Mehsi, follow this checklist:

-

Verify the manufacturer’s experience in producing notebook machines (years in operation, case-studies or sample installations).

-

Ask for references from other notebook makers in Bihar.

-

Request on-site machine demonstration or trial production.

-

Compare proposals on a like-for-like basis: identical features, speed, warranty, support terms.

-

Ensure the proposal includes spare parts list, expected lifespan of wearing parts, and preventive maintenance schedule.

-

Clarify delivery timelines and installation schedule in Mehsi or your plant location.

-

Confirm training support and availability of technical engineers visiting your site.

-

Negotiate payment structure — down-payment, delivery milestones, performance acceptance test.

Once you shortlist two or three vendors, seek quotations and negotiate based on your specific notebook types (size, binding style, volume regularity).

Benefits of Installing a Notebook Making Machine in Mehsi

Installing a high-quality notebook making machine in your production facility in Mehsi, Bihar, offers these key advantages:

-

Consistent Product Quality

Precision-cutting, uniform binding, and smooth finishing lead to notebooks that meet quality expectations of schools, offices, and retail buyers. -

Higher Output & Lower Cost per Unit

Automation reduces labour time per unit, decreases error-rate, and allows scaling of production volume. -

Ability to Offer Custom Sizes or Features

With the right machine you can produce unique notebook styles, special cover designs, or limited-edition notebooks for clients. -

Competitive Edge

Having advanced notebook manufacturing equipment gives you leverage in bidding for bulk orders (schools, publishers, promotional supplies). -

Long-Term Value

A well-maintained machine reduces downtime, increases durability, and improves your return on investment over years.

Maintenance & Operational Best Practices

To ensure your notebook making machine runs reliably over its lifetime, adopt these best practices:

-

Routine Preventive Maintenance

Regularly clean feed rollers, lubricate moving parts, inspect belts and blades. Set a schedule (daily / weekly / monthly) to inspect critical parts. -

Operator Training & Standard Operating Procedures (SOPs)

Have written procedures for machine start-up, quality check protocols, and emergency shut-off. Train staff thoroughly. -

Use Recommended Consumables

Use binding wires, cutting blades, adhesives (if any), and paper that meet supplier-specifications to avoid undue wear or damage. -

Keep Spare Part Inventory

Maintain critical spare parts like cutting knives, rollers, sensors, and binding feeders locally in Mehsi to minimize downtime. -

Monitoring & Quality Control

Inspect finished notebooks at regular intervals for alignment, binding strength, sheet cut quality, and surface finish. Adjust machine settings promptly. -

Periodic Calibration & Upgrades

As technology improves / you expand production volumes, consider upgrading modules (e.g. automated feeder add-ons, digital control interfaces, or IoT-based monitoring).

Adhering to these practices will help optimize uptime, prolong lifespan, and protect your investment.

Case Example (Hypothetical)

Here is a sample scenario for a startup in Mehsi wanting to produce school-notebooks:

-

Estimated monthly volume: 20,000 notebooks

-

Requested notebook specification: A5-size, 80 pages, wire-o binding, laminated cardboard cover

-

Required throughput: about 800 notebooks per hour, i.e. ~10 hours production per day

-

Quotation received from a Mehsi-based notebook machine manufacturer: automatic system priced at INR 15 lakh including installation and training, with a 12-month warranty.

-

Power rating: 5 kW, estimated monthly electricity cost (running 300 h/month): ~INR 12,000

-

Labour: Two operators per shift, initial training provided on-site by supplier

-

Pay-back period: Given sale price per notebook margin, expected return on investment within ~18 months

While this is just illustrative, it highlights how you can plan your capital budgeting, operating cost projection and expected returns before finalizing your machine purchase.

Conclusion

Choosing the right notebook making machine for your business in Mehsi, Bihar is more than just selecting the lowest-price equipment. It involves careful evaluation of automation level, production speed, quality specifications, maintenance support, and after-sales service from a trusted vendor. By prioritising local suppliers and manufacturers in Mehsi / Bihar, you gain advantages in logistics, service response time, regulatory compliance, and long-term operational reliability.