Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

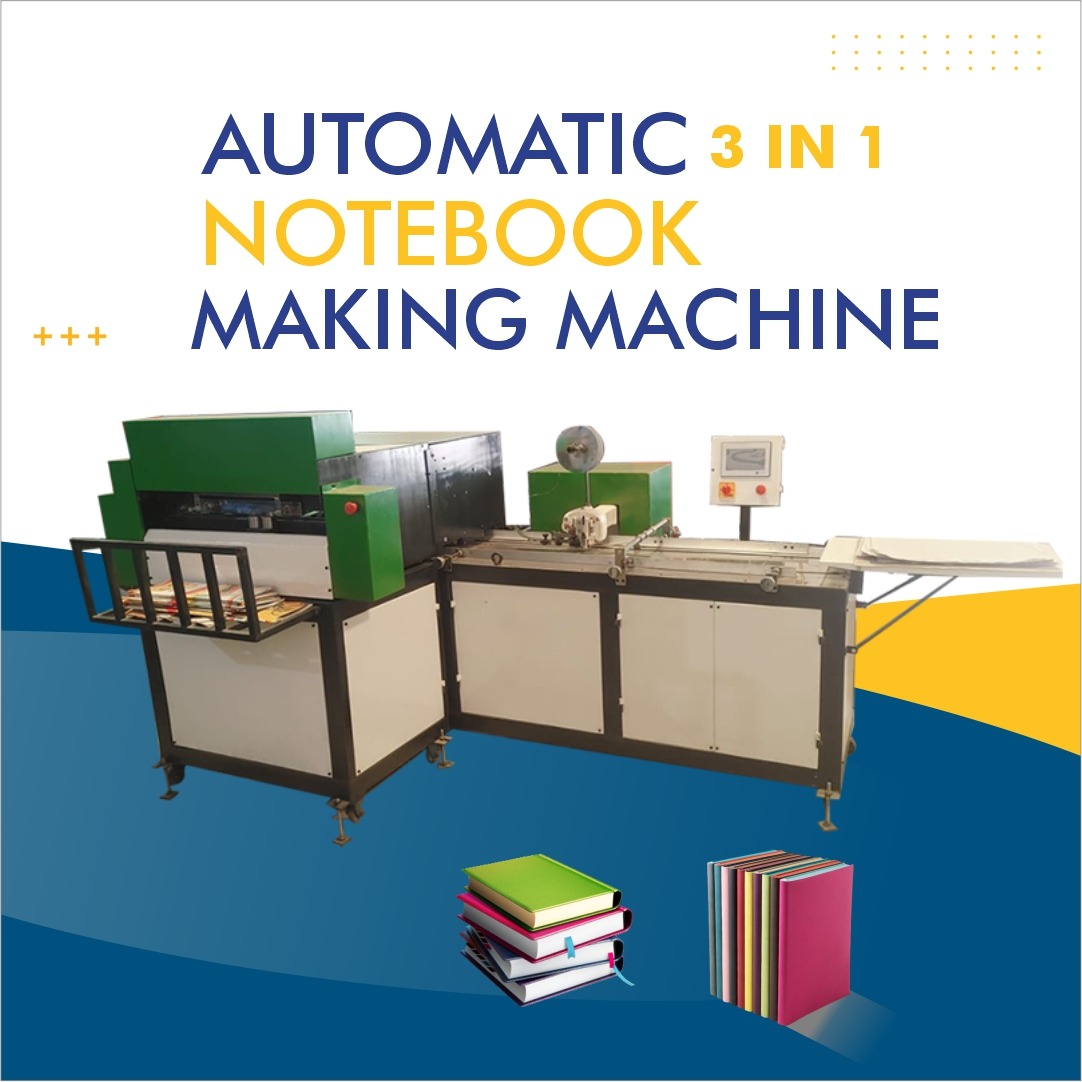

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Madhubani, Bihar | Automatic & Semi-Automatic Notebook Manufacturing Setup

Notebook Making Machine in Madhubani | Bihar

If you are searching for the best Notebook Making Machine in Madhubani, Bihar, this detailed guide will help you understand everything about the notebook manufacturing process, machinery types, setup cost, and business potential. Madhubani is emerging as a growing industrial area in Bihar, and the demand for quality notebooks, exercise books, and school copies is increasing day by day. Setting up a Notebook Manufacturing Machine can be a profitable small-scale or medium-scale business opportunity in this region.

Notebook manufacturing is a simple yet highly profitable venture. With the right Notebook Making Machine, high-quality raw materials, and minimal manpower, you can start a successful notebook production business catering to schools, colleges, and stationery suppliers across Bihar and nearby states.

What is a Notebook Making Machine?

A Notebook Making Machine, also known as a Notebook Manufacturing Machine or Exercise Book Making Machine, is industrial equipment designed to produce notebooks efficiently. These machines handle multiple processes such as ruling, cutting, stitching, binding, and pressing of notebooks.

There are different models available in the market depending on the level of automation you prefer—manual, semi-automatic, and fully automatic machines.

Main Functions of a Notebook Making Machine:

-

Paper Cutting: The machine cuts large paper reels into required sizes for notebooks.

-

Ruling and Printing: Lines or grids are printed for exercise or school notebooks.

-

Folding and Gathering: The printed sheets are folded and arranged in correct sequence.

-

Stitching or Binding: Pages are stitched or glued together using a Notebook Binding Machine.

-

Cover Pasting: The cover page is pasted or attached to the inner sheets.

-

Cutting and Trimming: Edges are neatly trimmed using a Notebook Cutting Machine for a finished look.

Types of Notebook Making Machines Available in Madhubani, Bihar

Depending on your budget and production needs, you can choose from several types of Notebook Making Machines:

1. Manual Notebook Making Machine

A cost-effective option for small-scale entrepreneurs or startups. Manual machines require physical operation but are ideal for low production volumes and beginners in Madhubani who are starting with limited capital.

2. Semi-Automatic Notebook Making Machine

Semi-automatic machines combine manual handling and mechanical automation. They increase productivity and maintain quality while reducing labor costs. Ideal for medium-scale notebook manufacturers in Bihar.

3. Fully Automatic Notebook Manufacturing Machine

These advanced machines automate almost all processes — from paper cutting to final binding. They are best suited for large production units and industrial notebook producers in Madhubani and nearby regions.

Key Features of Modern Notebook Production Machines

-

High-Speed Operation: Capable of producing thousands of notebooks per day.

-

Low Power Consumption: Energy-efficient motors reduce electricity costs.

-

Durable Construction: Built with high-grade steel for long operational life.

-

Easy Maintenance: Spare parts are easily available in the Indian market.

-

Compact Design: Requires minimal floor space.

-

Adjustable Settings: Can be configured for different notebook sizes.

-

Superior Output Quality: Ensures neat cutting, uniform stitching, and perfect binding.

Raw Materials Required for Notebook Manufacturing

To run a Notebook Manufacturing Machine efficiently, the following materials are needed:

-

Paper Reams or Rolls (white or ruled)

-

Cover Paper or Board

-

Gum and Adhesive

-

Thread or Wire for Stitching

-

Packaging Material

-

Ink for Ruling or Printing

These materials are easily available in Madhubani or nearby industrial markets like Darbhanga, Muzaffarpur, and Patna.

Notebook Making Process Step by Step

The complete process using a Notebook Production Machine includes:

-

Paper Cutting: Large sheets are cut to notebook size using a Paper Cutting Machine.

-

Printing & Ruling: Pages are ruled with lines or grids using a Ruling Machine.

-

Folding: The ruled papers are folded into notebook sections.

-

Gathering: The folded sheets are gathered to form a complete book.

-

Stitching: Pages are stitched together using a Copy Making Machine.

-

Binding: Covers are pasted, and edges are trimmed with a Notebook Binding Machine.

-

Finishing: The notebooks are pressed, stacked, and packed for distribution.

Business Opportunities in Madhubani, Bihar

The demand for stationery products in Bihar, particularly in educational districts like Madhubani, is increasing rapidly. With a growing number of schools, colleges, and coaching institutes, the consumption of notebooks and exercise books is at an all-time high.

By investing in a Notebook Making Machine in Madhubani, entrepreneurs can target the local and regional markets, including rural schools, government institutions, and private distributors. Local production reduces transportation costs and provides faster delivery.

Estimated Investment and Profit Margin

The cost of a Notebook Manufacturing Machine varies depending on type and production capacity.

| Type | Price Range (Approx.) | Production Capacity | Suitable For |

|---|---|---|---|

| Manual | ₹80,000 – ₹1,50,000 | 500 – 800 notebooks/day | Small startups |

| Semi-Automatic | ₹2,00,000 – ₹4,00,000 | 1500 – 2500 notebooks/day | Medium units |

| Fully Automatic | ₹6,00,000 – ₹12,00,000 | 4000 – 8000 notebooks/day | Large industries |

With consistent production and sales, the average profit margin in notebook manufacturing is 25% to 40%, depending on market demand and efficiency.

Advantages of Setting Up a Notebook Making Unit in Madhubani

-

Low Startup Cost: Machines and raw materials are affordable.

-

Growing Demand: Continuous requirement from schools and colleges.

-

Easy Availability of Labor: Skilled and semi-skilled workforce available locally.

-

Government Support: Bihar government offers incentives for MSME units.

-

Logistics Advantage: Easy connectivity to nearby markets like Darbhanga, Sitamarhi, and Patna.

Maintenance and After-Sales Support

Leading suppliers of Notebook Making Machines in Madhubani, Bihar offer installation, training, and maintenance services. Regular servicing ensures smooth operation and longer machine life. Always choose suppliers with reliable after-sales support and easy availability of spare parts.

How to Choose the Best Notebook Making Machine

When purchasing a Notebook Manufacturing Machine, consider these key factors:

-

Production Capacity

-

Automation Level

-

Power Requirements

-

Spare Parts Availability

-

Warranty and Service Support

-

Machine Build Quality

-

Customer Reviews

Compare quotations from multiple machine suppliers in Madhubani or nearby cities before finalizing.

Conclusion

Starting a Notebook Making Machine business in Madhubani, Bihar is a practical and profitable opportunity for entrepreneurs interested in the stationery and paper industry. With increasing educational awareness, notebook demand continues to rise. By selecting the right Notebook Manufacturing Machine, you can ensure efficient production, superior quality, and long-term business success.

Whether you opt for a Manual Notebook Machine, Semi-Automatic Notebook Machine, or Automatic Notebook Production Machine, Madhubani offers favorable conditions to establish a sustainable notebook manufacturing unit. Invest smartly, choose durable equipment, and build strong distribution channels to achieve consistent growth in the stationery industry.