Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

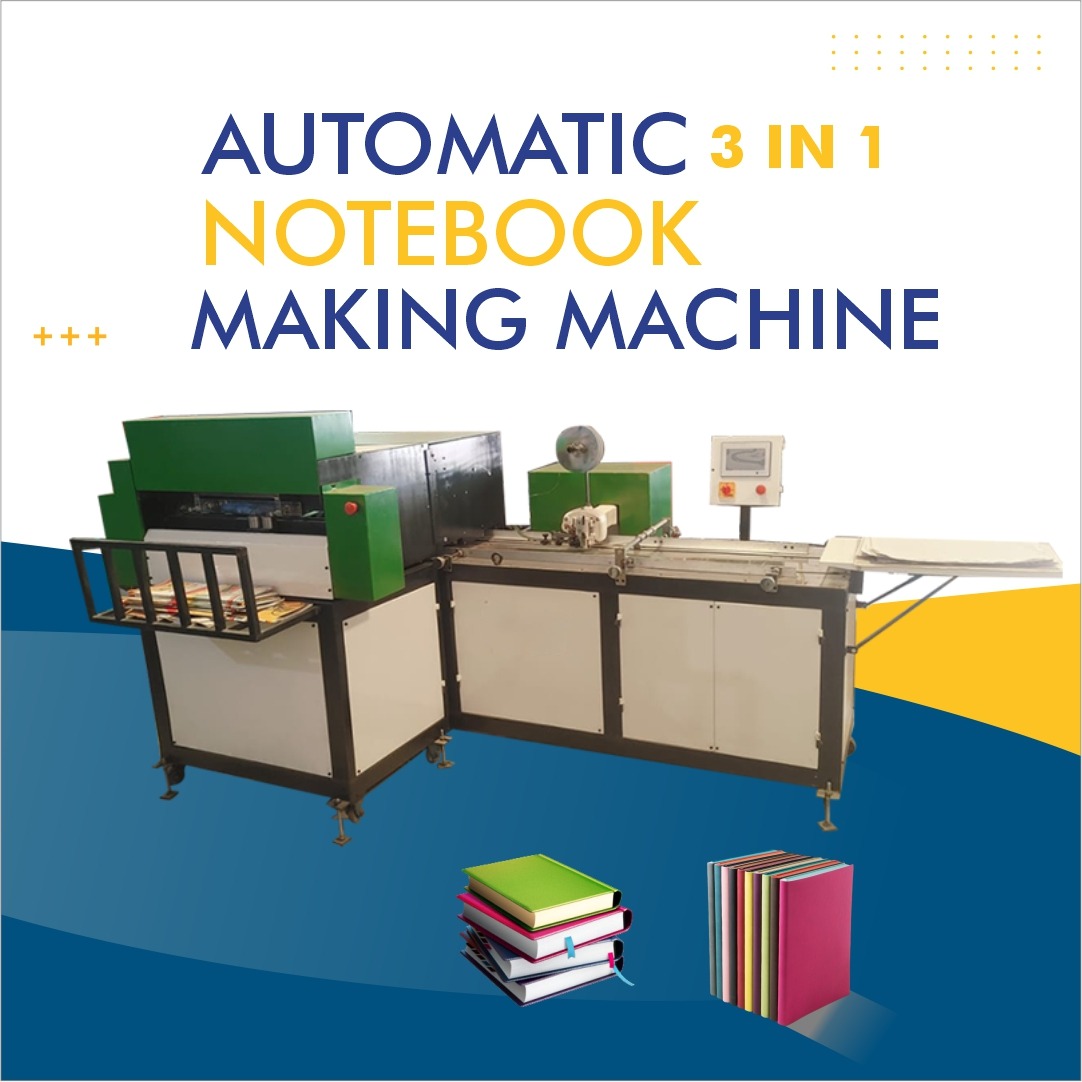

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Buy Notebook Making Machine Near Khagaria, Bihar – Best Supplier & Prices

Notebook Making Machine Near Khagaria | Bihar

In the growing stationery manufacturing sector across Bihar, setting up a reliable notebook production unit starts with choosing the right notebook making machine. For entrepreneurs in and around Khagaria district, having access to suitable machinery—automatic, semi-automatic or manual—is essential to ensure efficient production, good finishing, and cost-effective operations.

This guide will walk you through everything you need to know: what types of notebook making machines exist, what to consider when buying one near Khagaria, how to evaluate suppliers, cost factors, installation & maintenance, and local availability. By the end, you will have clearer visibility on selecting a notebook making machine for your business in Khagaria, Bihar.

Why Choose Notebook Making Machine for Your Business in Khagaria

-

Khagaria and neighbouring districts form part of the broader industrial belt in Bihar. Entrepreneurs can leverage relatively lower labor cost, good demand for stationery items, and connectivity to markets in Patna, Darbhanga, Bhagalpur etc.

-

Investing in a notebook making machine helps you scale production, improve consistency in size/shapes/binding quality, reduce manual labor, and meet bulk orders.

-

With increasing demand from schools, offices, local retailers, and institutional buyers in Bihar, having your own machinery reduces dependency on outsourcing production.

-

Proximity to suppliers and machinery dealers around Khagaria (or in nearby cities such as Patna) can lower freight and maintenance costs, and make servicing easier.

Types of Notebook Making Machines

Choosing the right type depends on production volume, budget, and technical capacity. Below are typical categories:

-

Manual Notebook Making Machine

-

Suitable for small-scale production, startups, or sample production.

-

Operated by hand for tasks such as cutting sheets, folding, stitching or binding manually or via semi-mechanical aids.

-

Lower cost, lower throughput.

-

-

Semi-Automatic Notebook Making Machine

-

Combines manual intervention for some steps (e.g. sheet feeding or cover alignment), with mechanical or electrical assistance in cutting, stitching or trimming.

-

Better throughput than manual; suitable for medium-scale production.

-

-

Fully Automatic Notebook Making Machine

-

All key processes (sheet cutting, corner cutting, binding, trimming, stacking) are handled by machine with minimal human intervention.

-

Higher cost, but much greater speed, consistency and scale.

-

Ideal when production demand is large (hundreds or thousands of notebooks per day).

-

-

Spiral / Wire-Bound Notebook Making Machine

-

Specialized machinery for spiral binding or wire binding notebooks.

-

Useful if you plan to produce spiral notebooks in addition to stitched notebooks.

-

-

Custom / Modular Machines

-

Some suppliers may offer modular configurations (e.g. upgradeable from semi-automatic to full automatic, or adding trimming / finishing attachments).

-

Benefit is flexibility and lower initial investment with future scalability.

-

Key Features & Specifications to Evaluate

When comparing different notebook making machines, consider these factors:

-

Production Capacity: notebooks per hour / day. Higher capacity machines cost more but reduce unit cost when your scale is high.

-

Size Range: supported paper sizes (e.g. A4, A5, custom), cover thickness, binding type.

-

Automation Level: manual / semi-automatic / fully automatic.

-

Power Requirements: single-phase or three-phase electricity; local energy supply in Khagaria area.

-

Material Compatibility: paper types, thickness, cover stock, binding thread or binding wire.

-

Precision & Finish Quality: how clean are the cuts; alignment; binding integrity.

-

After-sales Service & Spare Parts: ease of sourcing spare parts locally; availability of technical support from the seller.

-

Footprint & Floor Space: availability of workshop space in your factory.

-

Cost & Budget: upfront machine cost, installation cost, shipping/freight, customs (if imported), and running cost (power, maintenance, consumables).

Local Suppliers & Availability near Khagaria, Bihar

While there may not be large numbers of notebook making manufacturers strictly within Khagaria town itself, you can explore nearby listings and dealers:

-

Justdial lists Notebook Making Machine Manufacturers near Khagaria. Justdial

-

Many of the listed manufacturers or dealers are based in Patna or nearby areas. That means while you may not find every model locally in Khagaria, you can access suppliers within Bihar. Justdial

-

It is important to contact them to check whether they deliver to Khagaria, provide installation services there, and whether they offer spare parts in your region.

Local presence helps: you can visit showrooms, inspect a working demo, and negotiate better service agreements.

Cost Estimates & Price Range

Prices for notebook making machines vary broadly based on capacity, automation and brand. As a reference:

-

Fully automatic notebook making machines in India might cost in the range of ₹ 3,00,000 to ₹ 6,00,000 or more depending on capacity. (For example, an automatic notebook making machine listed by FOODMART Agro Engineering has a quoted price around ₹ 3,78,000. foodmarteng.com)

-

Lower cost semi-automatic or manual machines could cost significantly less, depending on features and build quality.

-

Transportation cost to Khagaria should also be accounted for since many suppliers are in Patna or further.

-

Installation, commissioning, and operator training may add to the overall capital expenditure.

Therefore, when budgeting your project, it’s wise to get multiple quotations from different suppliers, compare technical specs side by side, and include freight & installation cost.

How to Select the Right Machine for Khagaria-Based Setup

Here is a step-by-step checklist:

-

Estimate Your Production Volume

-

How many notebooks do you plan to produce per day or per month?

-

Do you need variation in sizes or binding types (stitched, spiral)?

-

-

Visit Local Dealers or Ask for Demonstration

-

Even if a supplier is based in Patna or elsewhere, request a demo in Bihar or ask for videos / sample products.

-

Check performance, quality of cut, binding strength, turnaround time.

-

-

Compare Technical Specifications

-

Motor power, speed, cutting accuracy, binding method, emergency safety features.

-

Verify whether the machine supports expansion or future upgrades (e.g. add spiral binding later).

-

-

Power & Infrastructure Review

-

Khagaria’s electricity supply may impose limitations (voltage fluctuations, capacity). Confirm the machine’s power requirement (single vs three-phase).

-

Ensure workshop has space, ventilation, and stable supply.

-

-

Spare Parts & Maintenance

-

Ensure that the vendor provides spare parts locally or delivers spares in a timely manner to Khagaria.

-

Ask about warranty, maintenance contract, and availability of technician visits.

-

-

Financial & Return on Investment (ROI)

-

Calculate how much additional revenue generation you expect by owning the machine (vs outsourcing).

-

Estimate cost per notebook (including materials, labour, depreciation of machine) to evaluate pay-back period.

-

-

Compliance & Quality Standards

-

Ensure binding strength meets requirements; if you deal with institutional orders (schools / government tenders), quality standards may matter.

-

Ensure safety standards and operator safety features in the machine.

-

Challenges & Considerations Specific to Khagaria, Bihar

While there are opportunities, there are also challenges to consider when setting up notebook manufacturing in Khagaria:

-

Transport & Logistics Delays: Delivery of heavy machinery to Khagaria may incur delays or extra freight charge compared to suppliers in metro cities.

-

Skilled Labour: Operating and maintaining automatic machinery requires some technical skills; you may need to hire or train local technicians.

-

Power Supply Reliability: Rural or semi-urban areas sometimes face inconsistent power supply or voltage fluctuations — so the machine must be robust or have safeguard features.

-

Market Competition & Pricing Pressure: Stationery is a competitive sector; you need to balance production cost vs quality to win contracts from schools, stationery shops or wholesale buyers.

-

Scale & Diversification: Initially you may produce standard stitched notebooks; in future you may want to diversify into spiral notebooks or custom formats — so choosing a machine with modular upgrade possibility helps.

Advantages of Investing in a Good Notebook Making Machine

If planned well, the advantages are significant:

-

Higher Throughput & Lower Unit Cost: Automating steps like cutting, trimming, stitching reduces manual labor and improves consistency, lowering wastage.

-

Consistent Quality & Reduced Rejects: Machine-based cutting and binding reduces errors and ensures uniformity.

-

Scalability: You can ramp up or diversify product lines once machinery is capable of different sizes / binds.

-

Competitive Advantage: Being able to deliver high volume or custom-order notebooks faster than competitors depending solely on manual methods.

-

Long-Term Savings: Although initial investment is high, over years the cost per unit often becomes substantially lower compared to manual or outsourcing.

Steps to Procurement & Implementation

Here is a suggested timeline for procuring and commissioning a notebook making machine in Khagaria:

-

Requirement Analysis & Business Plan – define output targets, product mix, capital & running cost.

-

Supplier Shortlisting & Quotation Requests – get 3–5 proposals with technical specs & prices.

-

On-Site Visit or Virtual Demo – check machine run on site or via video, review physical sample notebooks.

-

Order Placed & Payment Terms Negotiation – negotiate payment schedule, installation charges.

-

Delivery & Installation – coordinate transport to Khagaria, installation by vendor technicians.

-

Operator Training & Trial Runs – run sample production batch, check quality, adjust settings.

-

Full-Scale Production Launch – once quality is validated, ramp up output.

-

Maintenance & Upkeep – periodic maintenance schedule, spare-parts inventory, cleaning & lubrication, safety checks.

Conclusion

For entrepreneurs and small-to-medium industries around Khagaria, Bihar, investing in the right notebook making machine is a foundational step toward establishing a cost-efficient, scalable notebook manufacturing business. While suppliers may not all be located inside Khagaria town, proximity to Bihar-based dealers and manufacturers means you can source good machines at competitive prices with manageable logistics.

By carefully assessing your output needs, budget, technical requirements, and after-sales service, you can choose a machine that supports growth, maintains quality, and delivers good return on investment over time. With the right planning and execution, notebook manufacturing can become a sustainable and growing business in Khagaria and surrounding areas.