Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

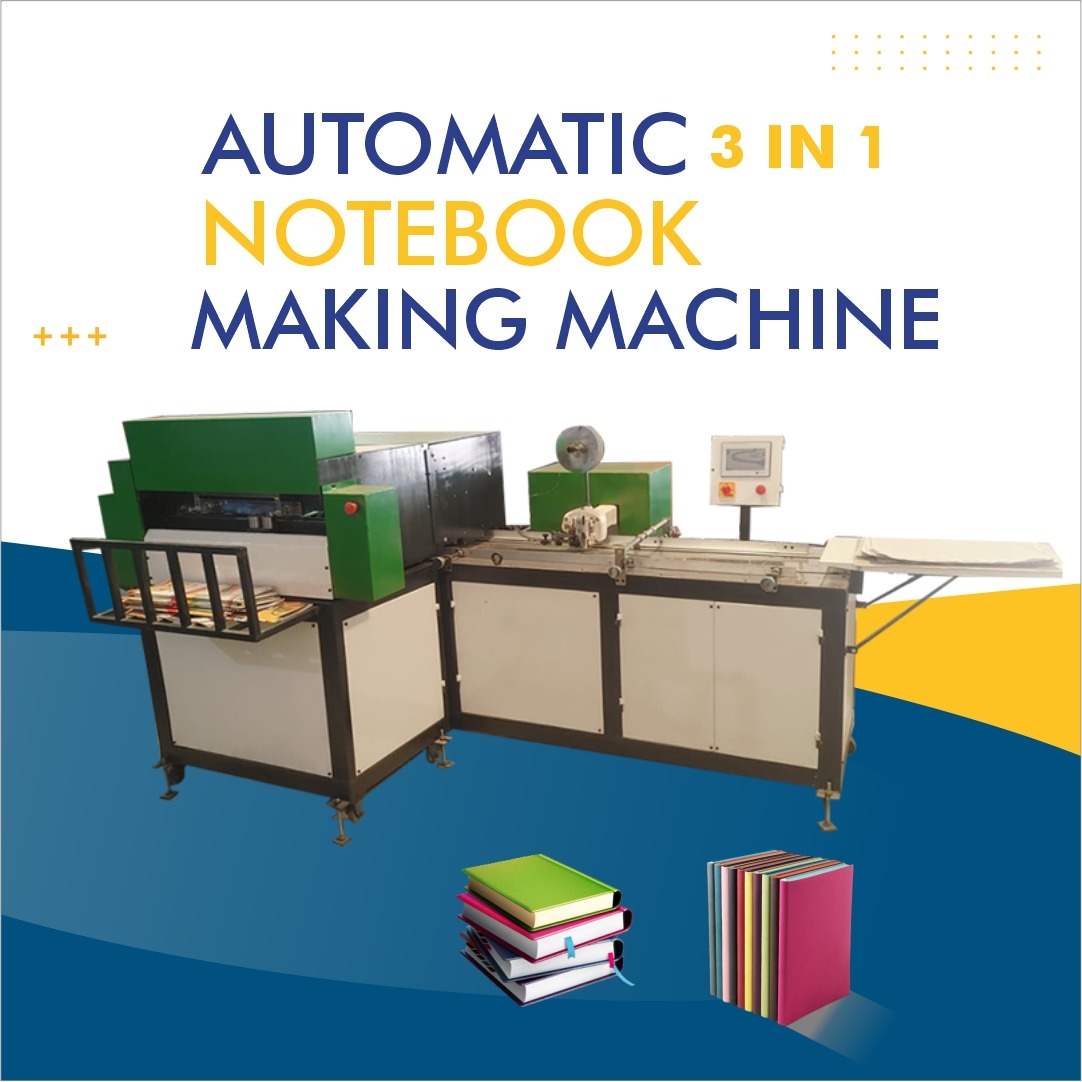

Notebook Making Machine Jamui Bihar – Reliable Supplier & Manufacturer

Notebook Making Machine Jamui | Bihar

In today’s competitive stationery industry, investing in a high-quality notebook making machine can make a significant difference to production capacity, quality, and overall profitability. If you are located in or around Jamui, Bihar, and searching for reliable equipment for notebook manufacturing, you’ve come to the right place. Whether you're planning to start a small-scale school notebook production business or expand an existing factory, choosing the right machine is critical to ensuring consistency, speed, and cost-efficiency.

This guide provides in-depth information about notebook making machines available in Jamui, Bihar, covering types, features, maintenance, cost considerations, and where to buy or install them locally. It also highlights how using the right equipment can help you stay ahead of the competition.

Why Choose a Local Supplier in Jamui, Bihar

-

Proximity & Service

Purchasing a notebook making machine from a nearby supplier near Jamui ensures faster delivery, easier installation, and on-site technical support. Downtime is minimized, and you can get maintenance help promptly. -

Understanding Local Requirements

Local supplier firms in Bihar are more likely to understand the regional demands: paper sizes used in local schools, the kind of paper available locally, government regulations (if any), and preferred binding styles. -

Cost Savings

Buying locally can reduce shipping costs, import duties, and delays. Local suppliers may also offer customizations tailored to your production goals. -

After-Sales Support & Spare Parts

A supplier near Jamui can ensure spare parts are available quickly and can support you with training for operators and periodic maintenance.

Types of Notebook Making Machines

Here are several types of machines that you might consider for your notebook production:

-

Manual Notebook Making Machine

Ideal for very small scale or startup production. Operators assemble pages and binding by hand with mechanical aid. Lower cost but slower output. -

Semi-Automatic Notebook Making Machine

This type automates some steps (page gathering, trimming, binding) while requiring human supervision for others. Great for medium-volume output. -

Automatic Notebook Making Machine

Fully mechanized system for continuous production. It handles cutting, page alignment, binding, and trimming with minimal manual intervention. Best for high-volume notebook production for schools or commercial sale. -

Spiral Binding Notebook Machine

Specifically designed for spiral bound notebooks (wire or plastic). It punches pages, inserts spirals, and trims edges. -

Glue-Binding / Hardcover Notebook Maker

Machines that apply adhesive binding or prepare hard covers. Useful if you plan to diversify beyond simple ruled notebooks.

Each type has its advantages. For example, an automatic notebook maker reduces time per unit and improves uniformity while a manual or semi-automatic device has lower capital cost and more control per unit.

Key Features to Look For

When evaluating different notebook making machines, particularly for your location in Jamui, consider these features:

| Feature | Importance |

|---|---|

| Production Speed | Determines how many notebooks you can produce per hour. Higher speed means higher capacity. |

| Sheet Size Compatibility | Ability to handle A4, A5, school exercise book sizes, custom ruled sizes. |

| Binding Options | Ruled binding, spiral binding, stitched or glued binding. |

| Automation Level | Manual, semi-automatic, or fully automatic. |

| Durability & Quality of Components | Robust build to handle long hours of operation and local conditions (dust, humidity). |

| Power Consumption | Efficient energy usage matters in locations with variable electricity supply. |

| Spare Parts Availability | Local availability of replacement blades, cutters, adhesive systems, rollers, electrical components. |

| Ease of Maintenance | Simpler design or modular units reduce maintenance downtime. |

| Safety Standards | Safety guards, emergency stop functions, and compliance with local industrial safety norms. |

| After-Sales Service | Whether the supplier provides installation, training, operational support and spare‐parts support near Jamui. |

Cost Considerations

When budgeting for a notebook making machine near Jamui, Bihar, consider the following cost elements:

-

Machine Purchase Price

Depending on automation level and capacity, prices vary significantly. Manual machines cost less but produce slower, while automatic machines cost more upfront. -

Shipping & Handling

Since Jamui is inland, delivery transport cost from manufacturer or warehouse must be factored in. -

Installation & Setup

Local technical staff may be needed to install and calibrate the machine properly for your target paper size and binding style. -

Training & Labour

Operator training costs, plus wages for staff. Semi-automatic and automatic machines usually require skilled technician supervision. -

Consumables & Spare Parts

Binding wires, spirals, glue, staples, inks (for printing ruled lines), and replacement blades or cutters. -

Power & Utilities

Electricity tariffs in Bihar and maintenance of backup power (if needed) for continuous operation. -

Maintenance & Downtime

Factor in preventive maintenance schedule and cost of breakdowns. A reliable local service reduces unplanned downtime and cost.

Benefits for Notebook Production in Jamui, Bihar

By investing in a quality notebook making machine in the Jamui region, you can reap multiple advantages:

-

Scalability

You can expand from small-batch production to supplying local schools, stationery shops, and possibly regional markets in Bihar. -

Quality Control

Automated machines ensure consistent page alignment, binding strength, and finished appearance, enhancing product credibility. -

Competitive Pricing

Lower per-unit cost due to higher throughput and lower wastage. You can offer competitive pricing to attract clients across Jamui and neighboring districts. -

Faster Turnaround

Local presence allows faster order processing for schools or bulk orders, ensuring you meet seasonal demands (e.g. new academic year). -

Customisation Options

With your own machine, you can produce notebooks with custom coverings, ruled margins, or special bindings like hardcover variations.

Installation & Maintenance Tips

To maximize the lifetime and performance of your notebook making machine:

-

Site Preparation

Ensure your production space in Jamui has stable flooring, adequate ventilation, clean environment, and regulated power supply. -

Operator Training

Train your staff for safe usage, adjustments, troubleshooting, and daily cleaning procedures. -

Routine Maintenance

-

Lubrication of moving parts

-

Checking alignment and calibration

-

Cleaning rollers, dust removal

-

Replacing worn blades or cutting edges

-

-

Scheduled Service Visits

Work out a maintenance agreement with your supplier to schedule periodic inspections and calibration. -

Quality Checks

Regularly inspect finished notebooks for binding quality, alignment, trimming precision, and ensure clients’ feedback is incorporated for adjustments. -

Spare-Parts Stocking

Keep a small inventory of critical replacement parts near Jamui to minimize downtime when issues arise.

How to Select the Right Machine Supplier near Jamui

When searching for a reputable supplier or manufacturer of notebook making machines in Bihar or near Jamui, follow these steps:

-

Research Local Vendors

Check for firms in Bihar that supply or manufacture paper-binding and notebook equipment. Visit their factory or showroom if possible. -

Review Machine Demonstrations

Ask for product demos showing speed, binding quality, binding strength, and finishing cuts. Inspect sample notebooks. -

Ask for Client References

Speak with other users in Bihar or nearby districts who have installed similar machines. Understand their practical experience with maintenance, reliability, and downtime. -

Compare Quotations

Evaluate based on machine specifications (speed, capacity), cost of ownership (energy, spares, labour), warranty terms, and after-sales service. -

Negotiate Local Customisations

Request adjustments for paper sizes commonly used in Jamui schools or local stationery norms, possibly custom rule lines or binding type. -

Check Local Approvals

While stationery equipment typically does not require heavy certification in Bihar, ensure electrical safety compliance and adherence to any district-level regulations.

Common Problems & Troubleshooting

Even after installation, you may encounter issues. Some common challenges and how to address them:

-

Misalignment of Pages

If pages shift during binding, recalibrate the alignment guides or re-adjust the feeder tray. Regularly check mechanical guides. -

Uneven Binding or Loose Edges

Ensure binding pressure settings are correct, adhesive temperature (if glue binding) is stable, or the spiral insertion tension is properly adjusted. -

Cutting Defects

Dull blades may lead to ragged edges. Schedule periodic blade sharpening or replacement. -

Frequent Downtime

Keep a log of machine faults. Use it to negotiate preventive maintenance with your supplier. Ensure operators perform regular cleaning to reduce wear. -

Power Fluctuations

Install voltage stabilisers or backup supply systems in Jamui, as irregular current supply may affect machine electronics or motors.

Case Study (Hypothetical for Jamui)

Jamui Stationery Works (hypothetical) invested in a semi-automatic notebook making machine in early 2025. Within six months:

-

They increased production from 300 to 1,200 notebooks per day.

-

Their per-unit cost declined by nearly 35% due to reduced labour and fewer rejected units.

-

They expanded orders to nearby blocks and started supplying to two schools in Jamui district.

-

Maintenance was handled by a local technician trained by the supplier, reducing downtime to less than 2 % monthly.

Such results highlight how choosing the right notebook making machine near Jamui can transform your stationery business.

Conclusion

If you are planning to set up or upgrade your notebook manufacturing operation in Jamui, Bihar, acquiring the right notebook making machine is a foundational step. By selecting a machine with appropriate automation level, robust build quality, and backed by a reliable local supplier for installation, spare parts, and service, you can ensure sustainable, scalable, and profitable operations.

Start by defining your production target (daily output), binding style (spiral, stitched, glued), preferred automation (manual / semi-automatic / automatic), and budget. Then compare local vendors, assess sample outputs, and negotiate installation and maintenance terms. With the right planning and machine selection, you can build a successful notebook production business in and around Jamui.