Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

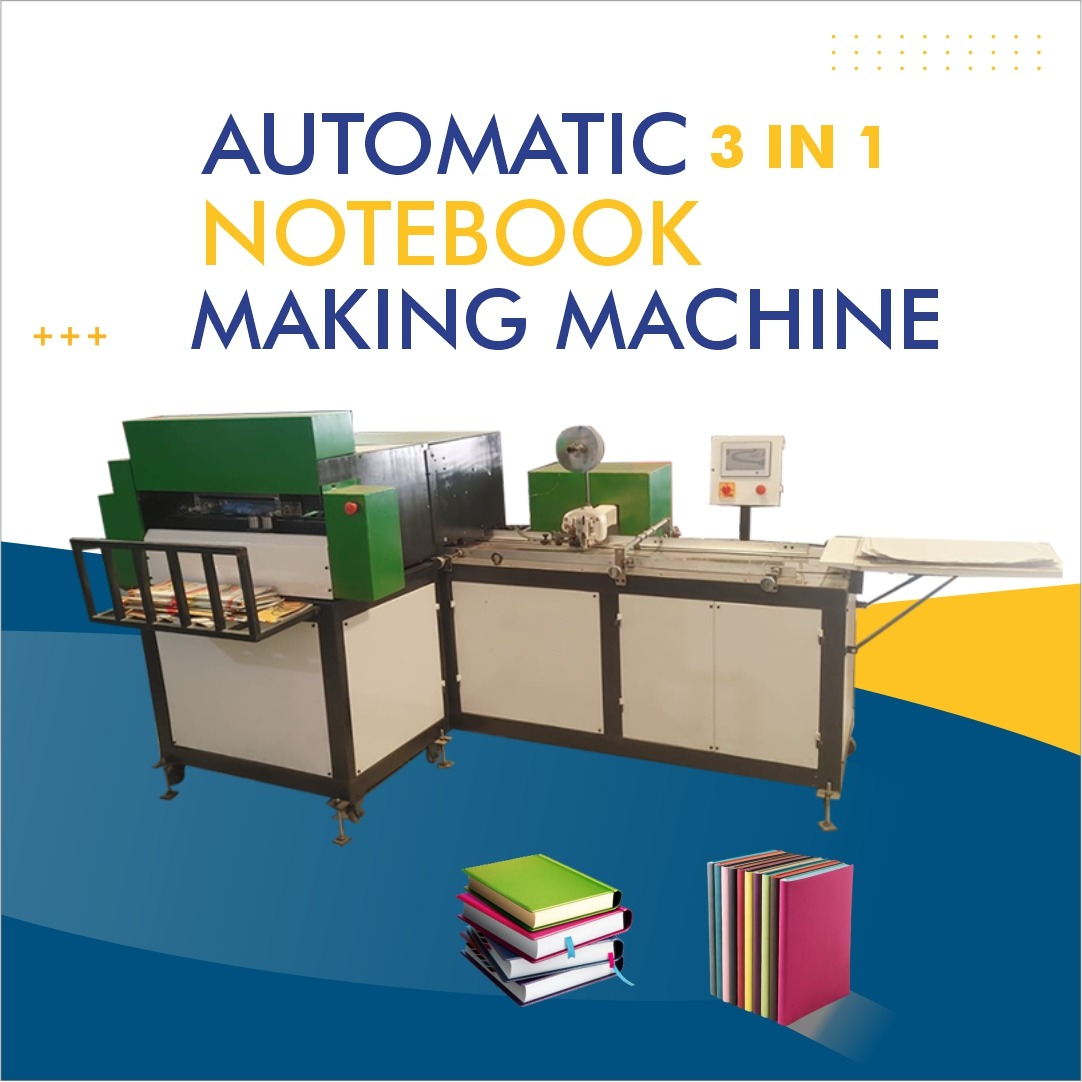

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Habibpur, Bihar | Durable & High Performance

Notebook Making Machine in Habibpur | Bihar

In the modern stationery industry, Notebook Making Machines play a vital role in ensuring efficiency, precision, and high-quality production. Businesses in Habibpur, Bihar seeking to expand their notebook manufacturing operations can benefit significantly by investing in advanced and reliable notebook making equipment. These machines are designed to streamline the production process, reduce manual labor, and increase output without compromising on quality.

What is a Notebook Making Machine?

A Notebook Making Machine is specialized equipment designed to automate the notebook production process. These machines are equipped with cutting, binding, and punching systems that ensure uniform and durable notebooks. They are widely used in educational stationery production, offices, and commercial stationery businesses. By integrating modern technology, notebook machines allow manufacturers to produce notebooks of various sizes, types, and designs efficiently.

Key Synonyms:

-

Automatic Notebook Machine

-

School Notebook Machine

-

Stationery Production Machine

-

Spiral Notebook Machine

Importance of Notebook Making Machines in Habibpur, Bihar

Habibpur is emerging as a hub for stationery manufacturing in Bihar. Businesses are increasingly investing in Notebook Making Machines to meet local and regional demands. The benefits include:

-

Increased Productivity: Automated machines can produce hundreds of notebooks per hour, significantly boosting output.

-

Consistency & Quality: Machine-based production ensures uniformity in size, binding, and paper alignment.

-

Cost Efficiency: Reduces labor costs and wastage of raw materials.

-

Flexibility: Machines can handle various notebook types, including spiral, hardbound, softbound, and ruled notebooks.

-

Market Competitiveness: Businesses can scale up production to meet market demands, improving profitability.

Types of Notebook Making Machines

Notebook manufacturing machines come in different types depending on the binding method, production capacity, and features:

1. Manual Notebook Making Machine

Suitable for small-scale businesses, these machines require manual intervention but are cost-effective.

2. Semi-Automatic Notebook Making Machine

Semi-automatic machines combine manual effort with automated processes to increase efficiency while maintaining affordability.

3. Fully Automatic Notebook Making Machine

Fully automatic machines are ideal for large-scale production. They automate cutting, folding, binding, and punching, ensuring high-speed production with minimal human intervention.

4. Spiral Notebook Making Machine

Specifically designed for spiral-bound notebooks, these machines handle punching, coil insertion, and binding automatically.

5. Writing & School Notebook Making Machine

These machines are customized for school and office notebooks with specific ruling, paper size, and binding standards.

Features to Look for in a Notebook Making Machine

When investing in a Notebook Making Machine in Habibpur, Bihar, consider these essential features:

-

High-Speed Production – Machines with higher production capacity reduce lead time.

-

Durable Construction – Strong frames and quality components ensure long-term reliability.

-

Multiple Notebook Formats – Capability to produce different sizes and designs.

-

Easy Maintenance – Machines with simple maintenance procedures save downtime.

-

Energy Efficient – Low power consumption machines reduce operating costs.

-

Precision Cutting & Binding – Ensures professional and consistent quality.

Benefits of Buying a Notebook Making Machine in Habibpur

Investing in a Notebook Making Machine in Habibpur, Bihar, offers significant advantages:

-

Local Support: Machines purchased locally have easier access to technical support and spare parts.

-

Reduced Lead Time: No import delays; machines are immediately available for installation.

-

Customized Solutions: Local suppliers understand the market requirements and can provide tailored machinery.

-

Cost Savings: Lower shipping and transportation costs make local procurement economical.

Notebook Manufacturing Process Using Machines

The notebook making process with advanced machinery involves several stages:

-

Paper Cutting – Precise cutting of sheets to the required size.

-

Folding & Gathering – Sheets are folded and arranged in correct order.

-

Binding – Different methods like stitching, gluing, or spiral binding.

-

Punching & Coil Insertion – For spiral notebooks, holes are punched, and coils inserted automatically.

-

Cover Attachment – Hard or soft covers are attached as per design.

-

Trimming & Finishing – Final trimming ensures neat edges and professional finish.

Using machines ensures speed, accuracy, and uniformity across every notebook produced.

How to Choose the Right Notebook Making Machine

Choosing the perfect machine depends on your business requirements:

-

Production Capacity – Assess your daily or monthly notebook production target.

-

Type of Notebooks – Decide whether you need spiral, softbound, or hardbound notebooks.

-

Automation Level – Small businesses may opt for semi-automatic machines, while larger operations need fully automatic machines.

-

Budget – Factor in both the purchase cost and operating cost.

-

Local Supplier Support – Ensure the supplier provides installation, training, and after-sales service.

Popular Notebook Making Machine Brands in Bihar

Several manufacturers and suppliers provide reliable Notebook Making Machines in Bihar. Opting for trusted brands ensures quality, durability, and efficient operation. Always compare features, warranty, and user reviews before making a purchase.

Maintenance Tips for Notebook Making Machines

To maximize lifespan and efficiency:

-

Regular Cleaning – Remove paper dust and debris to avoid jamming.

-

Lubrication – Oil moving parts periodically to prevent wear and tear.

-

Periodic Inspection – Check for loose bolts, worn-out parts, or damaged electrical components.

-

Use Recommended Materials – Only use paper and binding materials compatible with the machine.

-

Professional Servicing – Engage trained technicians for major repairs or calibration.

Cost of Notebook Making Machines in Habibpur

The price of a Notebook Making Machine in Habibpur varies depending on capacity, automation level, and features. Manual machines are more affordable, while fully automatic machines cost higher but provide a faster ROI through increased production and reduced labor costs.

Why Habibpur is the Ideal Location for Notebook Manufacturing

Habibpur offers a strategic advantage for notebook manufacturing due to:

-

Proximity to paper suppliers

-

Skilled labor availability

-

Lower operational costs compared to metropolitan areas

-

Growing local and regional demand for notebooks

-

Easy connectivity for distribution across Bihar and neighboring states

Conclusion

Investing in a high-quality Notebook Making Machine in Habibpur, Bihar, is a smart decision for stationery businesses aiming to increase productivity, reduce labor dependency, and meet market demand efficiently. By selecting the right machine type, ensuring proper maintenance, and leveraging local supplier support, businesses can achieve long-term profitability and sustained growth.

Whether you are starting a small stationery business or scaling an existing manufacturing unit, a reliable notebook making machine is an indispensable tool that ensures precision, consistency, and high output.