Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

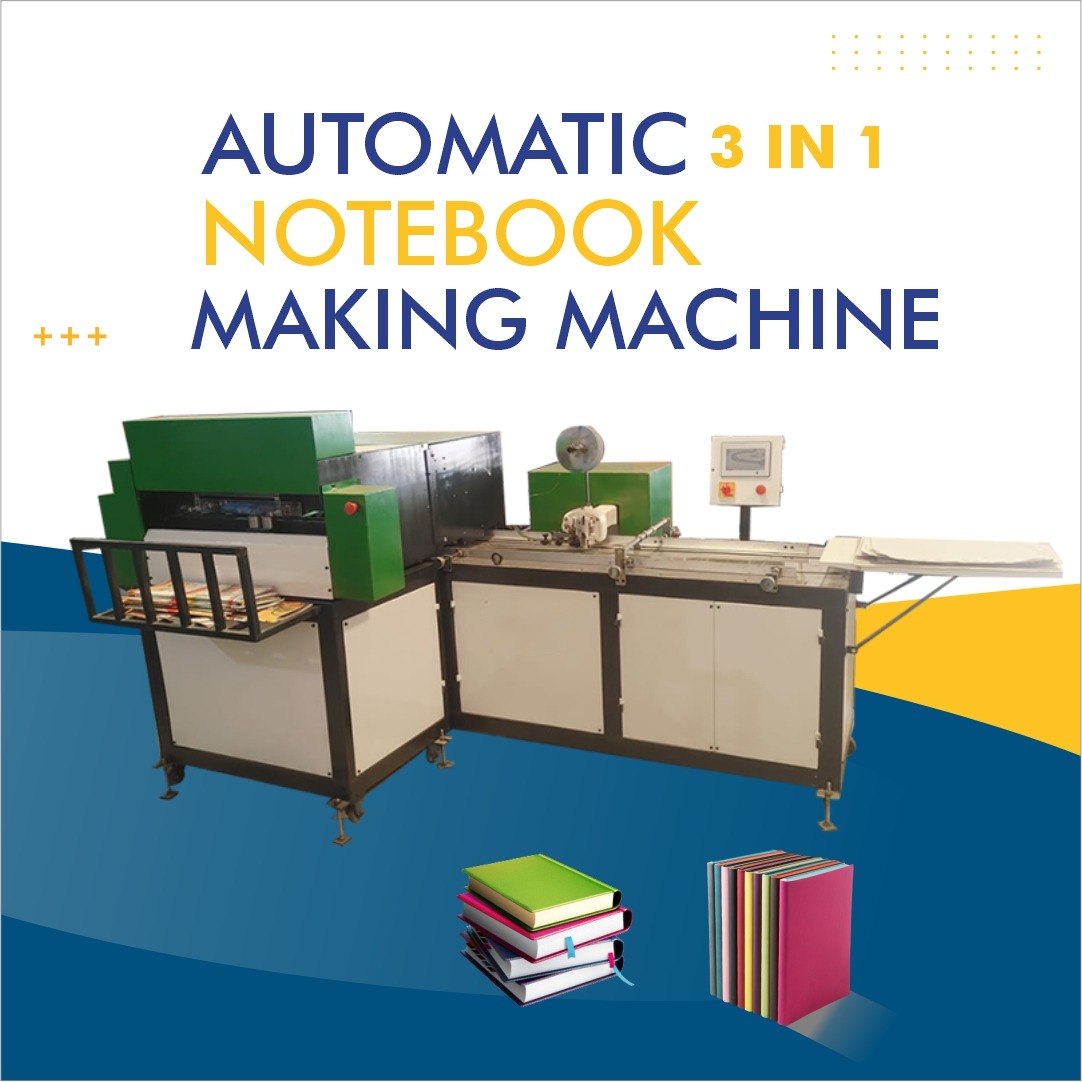

Buy Notebook Making Machine in Dehri Bihar – Automatic & Semi-Automatic Solutions

Notebook Making Machines in Dehri | Bihar

Notebook making machines have become an essential asset for the stationery manufacturing industry, especially in regions like Dehri, Bihar. As demand for notebooks continues to rise in schools, colleges, and offices, investing in high-quality notebook manufacturing equipment ensures a steady supply and improved efficiency.

Dehri Bihar, being an emerging industrial hub, offers significant opportunities for businesses looking to establish or expand notebook production. Local manufacturers now have access to both automatic and semi-automatic notebook making machines, catering to varying production scales and budget requirements.

The notebook making machine is designed to streamline the entire process of notebook production, from paper cutting to binding and final finishing. These machines are engineered for precision, speed, and reliability, helping manufacturers meet high-quality standards while reducing manual labor.

Types of Notebook Making Machines

-

Automatic Notebook Making Machine

Automatic notebook machines are highly efficient and are ideal for large-scale production. These machines can handle multiple steps of notebook manufacturing, including paper stacking, stitching, binding, and trimming, all in a single operation. Businesses in Dehri, Bihar, prefer automatic machines for their speed, accuracy, and reduced manpower requirements. -

Semi-Automatic Notebook Making Machine

Semi-automatic machines are suitable for medium-scale production units. While some processes require manual intervention, semi-automatic machines offer flexibility and are more affordable compared to fully automatic machines. This type is widely adopted by small and medium entrepreneurs in Dehri, Bihar, who are looking for cost-effective solutions without compromising on quality. -

Notebook Binding Machine

Binding is a crucial step in notebook manufacturing. Notebook binding machines ensure that pages are securely stitched or glued together, providing durability and a professional finish. Modern machines come with adjustable settings for different notebook sizes and cover types, making them versatile for manufacturers in Bihar. -

Notebook Production Equipment

Notebook production equipment includes machines for cutting, laminating, stitching, and trimming. Investing in a full set of notebook manufacturing machinery allows businesses to produce high-quality notebooks consistently while maintaining productivity.

Advantages of Investing in Notebook Making Machines

-

High Efficiency and Productivity: Notebook machines drastically reduce production time compared to manual processes. Manufacturers in Dehri, Bihar, can increase output and meet growing market demands efficiently.

-

Consistent Quality: Automatic and semi-automatic machines ensure uniformity in notebook size, page alignment, and binding quality. This consistency enhances brand reputation and customer satisfaction.

-

Cost-Effective: Though initial investment may vary, notebook machines reduce labor costs and wastage, resulting in long-term savings.

-

Versatility: Modern machines can handle different paper sizes, thicknesses, and binding styles. This flexibility allows manufacturers to produce a variety of notebooks, including school notebooks, office notebooks, and premium notebooks.

-

Durability: High-quality notebook making machines are built to last and can handle continuous production without frequent maintenance, making them a smart investment for businesses in Bihar.

Notebook Manufacturing Process Using Machines

-

Paper Cutting

The first step involves cutting large sheets of paper into the required notebook size. Automatic paper cutting machines ensure precise measurements and reduce wastage. -

Folding and Stacking

Cut sheets are folded and stacked according to the notebook design. Machines automate this process to maintain uniformity across all units. -

Binding and Stitching

The stacked pages are stitched or glued together using notebook binding machines. This process is crucial for notebook durability and usability. -

Covering and Laminating

Notebook covers are added, and optional lamination can be done to enhance appearance and protection. High-speed laminating machines in Dehri help achieve professional results efficiently. -

Trimming and Finishing

The final step involves trimming excess edges and ensuring smooth finishes. Automatic trimming machines help produce notebooks with precise dimensions, giving them a clean, professional look.

Why Choose Dehri Bihar for Notebook Making Machines

Dehri, Bihar, has emerged as a hub for small and medium-scale manufacturing units. The advantages of investing in notebook making machines in this location include:

-

Strategic Location: Easy access to raw materials and transportation networks across Bihar and neighboring states.

-

Skilled Workforce: Availability of trained technicians and machine operators ensures smooth operations and maintenance.

-

Affordable Costs: Competitive pricing for machinery and operational costs make Dehri an attractive destination for notebook manufacturing businesses.

-

Support and Services: Local suppliers provide reliable installation, maintenance, and spare parts services, minimizing downtime for production units.

Key Features of Modern Notebook Making Machines

-

High-speed production capacity for large-scale manufacturing.

-

Adjustable settings for different notebook sizes and page counts.

-

Energy-efficient operation to reduce electricity costs.

-

Easy-to-use control panels and automation for error-free operation.

-

Durable construction using high-quality materials to withstand continuous use.

Tips for Choosing the Right Notebook Making Machine

-

Assess Production Needs

Determine the number of notebooks you plan to produce daily to choose between automatic and semi-automatic machines. -

Consider Budget

While automatic machines are more expensive, they offer higher productivity. Semi-automatic machines are ideal for budget-conscious entrepreneurs. -

Check Machine Specifications

Ensure the machine can handle desired notebook sizes, binding styles, and cover types. -

After-Sales Support

Choose suppliers in Dehri Bihar who provide installation, maintenance, and spare parts support. -

Energy Efficiency

Opt for machines with low power consumption to save on operational costs in the long run.

Conclusion

Investing in a notebook making machine in Dehri Bihar is a strategic decision for manufacturers aiming to capitalize on the growing stationery market. With options ranging from automatic to semi-automatic machines, businesses can find equipment that meets their production requirements and budget. High-quality notebook machines ensure efficient, consistent, and cost-effective notebook manufacturing, allowing businesses to deliver premium products to schools, colleges, and corporate clients.

Whether you are starting a new notebook production unit or expanding an existing one, Dehri Bihar provides the infrastructure, skilled workforce, and local support to make your investment successful.

By choosing the right notebook making machine, manufacturers can streamline production, reduce wastage, and maintain consistent quality, ensuring long-term profitability in the competitive stationery market.