Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

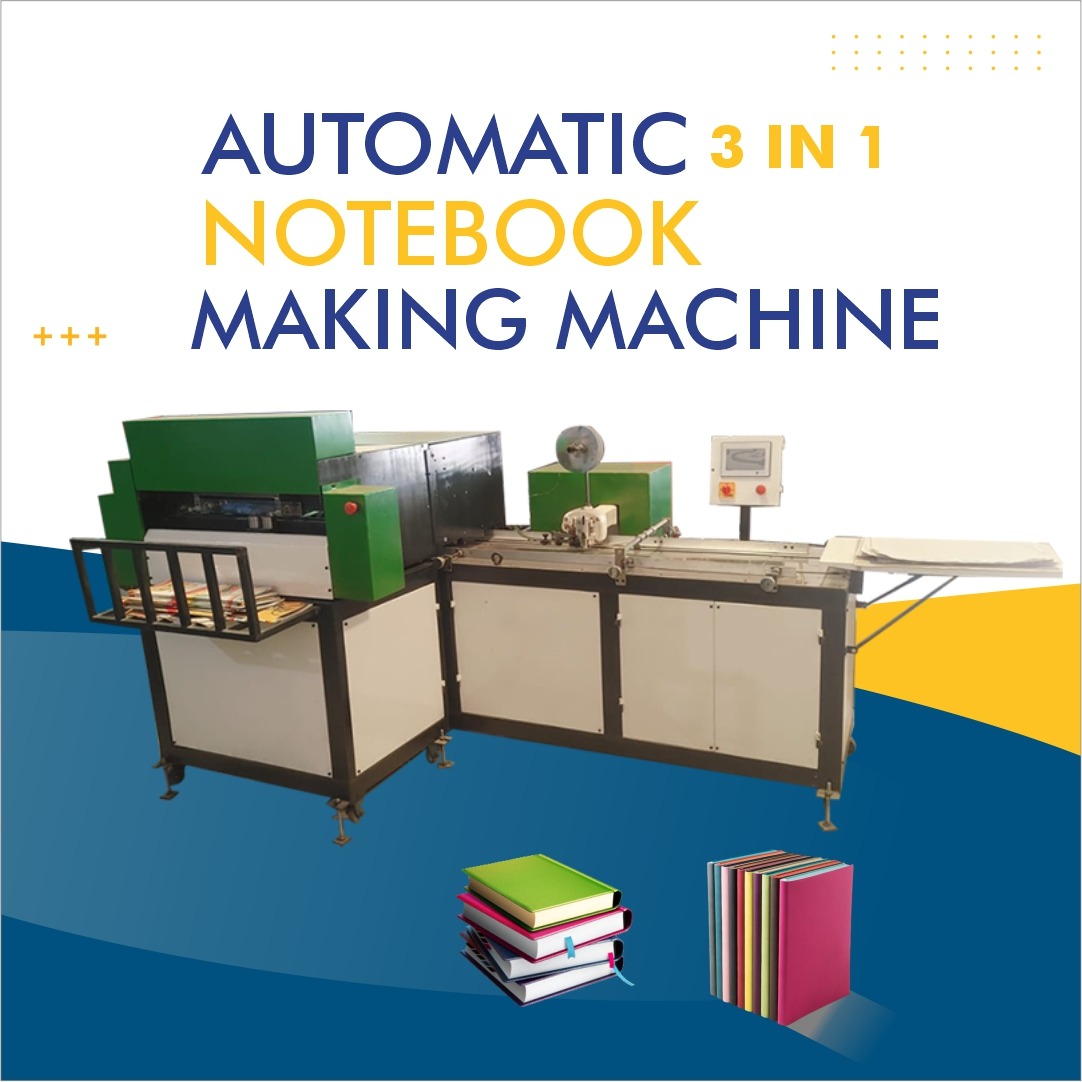

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Bikram Bihar – Manual, Semi-Automatic & Automatic Equipment

Notebook Making Machine in Bikram | Bihar

Bikram, Bihar, represents a promising location for setting up or expanding notebook production facilities. If you are in search of a notebook making machine, either manual or fully automatic, for use in or around Bikram, this guide will give you a comprehensive overview of the types, applications, selection criteria, benefits and local support for such equipment.

In this article, you will find details on various notebook making machines, their specifications, types (manual / semi-automatic / automatic), the advantages of locating operations in Bikram Bihar, how to choose the right equipment, cost and maintenance considerations, and why investing in quality notebook production machinery will benefit your venture.

Why Choose Bikram, Bihar for Notebook Making Machinery

-

Industrial Development & Incentives

Bihar Industrial Area Development Authority (BIADA) oversees multiple industrial clusters and provides infrastructure support to manufacturing businesses. Wikipedia

New manufacturing units are being promoted by the state government. The New Indian Express

If you are planning to install a notebook making machine in or near Bikram, you may benefit from local industrial policies, potential subsidies, or facilitations via BIADA or state agencies. -

Availability of Labour and Raw Materials

Notebook production requires raw materials like paper, card board, binding wires or adhesives, cover stock and finishing. The proximity to Patna and other industrial supply networks makes Bikram viable for steady sourcing of raw materials and labour. -

Logistics & Market Proximity

Being in Bihar, setting up near Bikram allows you to serve educational institutions, stationery wholesalers across the state, and neighbouring regions (Uttar Pradesh, Jharkhand, etc.). Lower freight cost and ease of distribution help reduce overall unit-cost for notebooks produced using your notebook production machine. -

Growth Potential

With rising literacy rates, school enrollment, and demand for notebooks across government programs (e.g. mid-day meals, school supplies), there is growing opportunity for stationery manufacturing. Investing in a high-quality notebook making machine positions you to meet both commercial and institutional demand.

Types of Notebook Making Machines

When selecting machinery for notebook production, you have several options. Here are the main categories:

| Type | Description | Typical Use Case |

|---|---|---|

| Manual Notebook Making Machine | Requires significant manual effort. Suitable for small-scale or startup production | Low budget operations, customized notebook batches |

| Semi-Automatic Notebook Making Machine | Allows mechanised operations for cutting, stitching or binding while some steps are manual | Medium scale manufacturing |

| Automatic Notebook Making Machine | Fully mechanised end-to-end process: cutting, stitching, folding, binding | High volume production with lower labour cost |

Examples of these machines are available in India: SBS offers manual notebook making machinery with capacity of about 3,000 notebooks/day. sbsmachine.com

Also, ASV Engineering offers semi-automatic and automatic versions with different sheet sizes and binding capacities. asveng.com

Key Specifications to Consider

When choosing a notebook production machine, evaluate these specifications:

-

Production Capacity

How many notebooks per day or per hour? Manual machines may offer lower capacity (hundreds to thousands per day), while automatic machines may produce several thousands or more. -

Automation Level

Manual vs. semi-automatic vs. fully automatic. Higher automation reduces labour cost but increases initial investment. -

Machine Size and Format

Maximum sheet size / cutting width (e.g. 32”, 36”), maximum notebook thickness (number of pages), binding type (centre-stitch, glue binding, spiral binding if applicable), finishing options. -

Power Requirements

Voltage, phase (e.g. single-phase or three-phase), energy consumption (kW rating). Ensure local power supply in Bikram meets those requirements. -

Material Quality

Frame and body material (mild steel, stainless steel), wear-resistant parts (cutting dies, stitching heads), safety features. -

Maintenance & Support

Availability of spare parts and technical support in Bihar / nearby region. Ensure the vendor offers installation, warranty and after-sales service. -

Cost & Return on Investment (ROI)

Initial cost of machine, running cost (electricity, labour, consumables), yield rate (percentage of good notebooks produced), scrap/waste rate, payback period.

Synonyms / Alternate Terms (Repeated Within the Text)

To improve SEO reach, here are alternate keywords used throughout:

-

book binder machine

-

binding machine equipment

-

notebook stitching unit

-

stationery production machine

-

notebook binding apparatus

These refer to variations of the same core idea — machinery used to manufacture notebooks by cutting, stitching, binding and finishing operations.

Setting Up Production in Bikram with Your Notebook Making Machine

Layout Planning

Design your production floor considering the footprint of the machine. Automatic machines tend to be larger and may require dedicated space, ventilation, safety clearance, and material flow routes (incoming paper, cutting waste disposal, finished stacks).

Regulatory Compliance

Check local municipal and environmental regulations for noise, waste disposal, dust control. If your operations include cutting paper or adhesives, ensure compliance with local standards in Bihar.

Labour Training

If you select a semi-automatic or automatic notebook production machine, your staff will require training for operation, maintenance schedules, quality checks, and simple repairs. Ensuring skilled operators will reduce downtime and improve yield.

Quality Standards

Use quality raw materials and periodic inspections (page alignment, binding strength, finish). Consistent quality is crucial for institutional orders (schools, government tenders), especially in Bihar where many supply contracts require specific durability standards.

Competitive Landscape & Suppliers

While Bikram may not yet host major notebook-machine manufacturers, you can source machinery from vendors across India:

-

SBS Machine (manual / semi-automatic notebook making equipment) sbsmachine.com

-

ASV Engineering (semi-automatic and automatic notebook making machine models) asveng.com

-

Other manufacturers listed via TradeIndia or Justdial for notebook making machines. TradeIndia+1

You can request quotes, inspect machine demonstrations, and arrange shipping to Bikram, Bihar. Consider folding in freight and custom local assembly to reduce setup time.

Cost Factors & Estimate

Here’s a rough outline of cost drivers:

| Cost Item | Description |

|---|---|

| Equipment Price | Manual machines tend to start lower; semi-automatic and automatic machines cost more (lakhs to tens of lakhs INR depending on capacity) |

| Shipment & Transport | From manufacturer’s location to Bikram, Bihar |

| Installation & Commissioning | Technician visit / setup cost |

| Power Infrastructure | Ensuring adequate electrical wiring, phase supply, backup if required |

| Consumables | Binding wires, glue, cover laminates, paper trimming waste disposal |

| Labour Cost | Operators, maintenance staff |

You should calculate your expected annual production volume, expected price per notebook, operating cost per unit, and derive your break-even period. Higher initial investment in an automatic notebook making machine can be justified if your production volume is high and labour cost is significant.

Marketing Your Notebook Products

Once your machine is installed and production begins, consider these strategies:

-

Local schools & educational institutions in and around Patna and other Bihar districts

-

Stationery wholesalers and retailers

-

Government tenders for supplying exercise books / notebooks

-

Branding & Quality Differentiation — e.g. eco-friendly paper, customized covers, special finishes

-

Online sales — tie-up with e-commerce platforms for bulk orders

Advantages of Investing in a Good Machine

-

Consistent Quality & Uniformity — automated cutting, stitching and binding yield better finish than manual operations

-

Higher Throughput — you can fulfil large orders faster with automatic or semi-automatic notebook production machine

-

Reduced Labour Dependency — automation reduces reliance on skilled manual labour

-

Scalability — upgrading or expanding capacity is easier using modular or scalable machines

-

Better Margins — less wastage, improved yield, ability to negotiate bulk raw material supplies

Challenges & Mitigation

-

Power Fluctuations — Ensure you have stable three-phase supply, possibly UPS or surge protection

-

Maintenance Downtime — plan preventive maintenance schedule; keep spare parts inventory

-

Supply Chain Disruptions — ensure reliable supplier relationship for paper stock, adhesives, binding wires

-

Regulatory Delays — obtaining permissions / clearances; engage with BIADA or local authorities early

Conclusion

If you are considering investing in a notebook making machine in Bikram, Bihar, the opportunity is promising. By selecting the right type of machine (manual, semi-automatic or automatic), ensuring specifications match your production goals, and securing local support and supply chains, you can build a sustainable notebook production business.

With the right notebook production machine and careful planning, you can serve both local and regional stationery markets and deliver high-quality notebooks efficiently.