Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

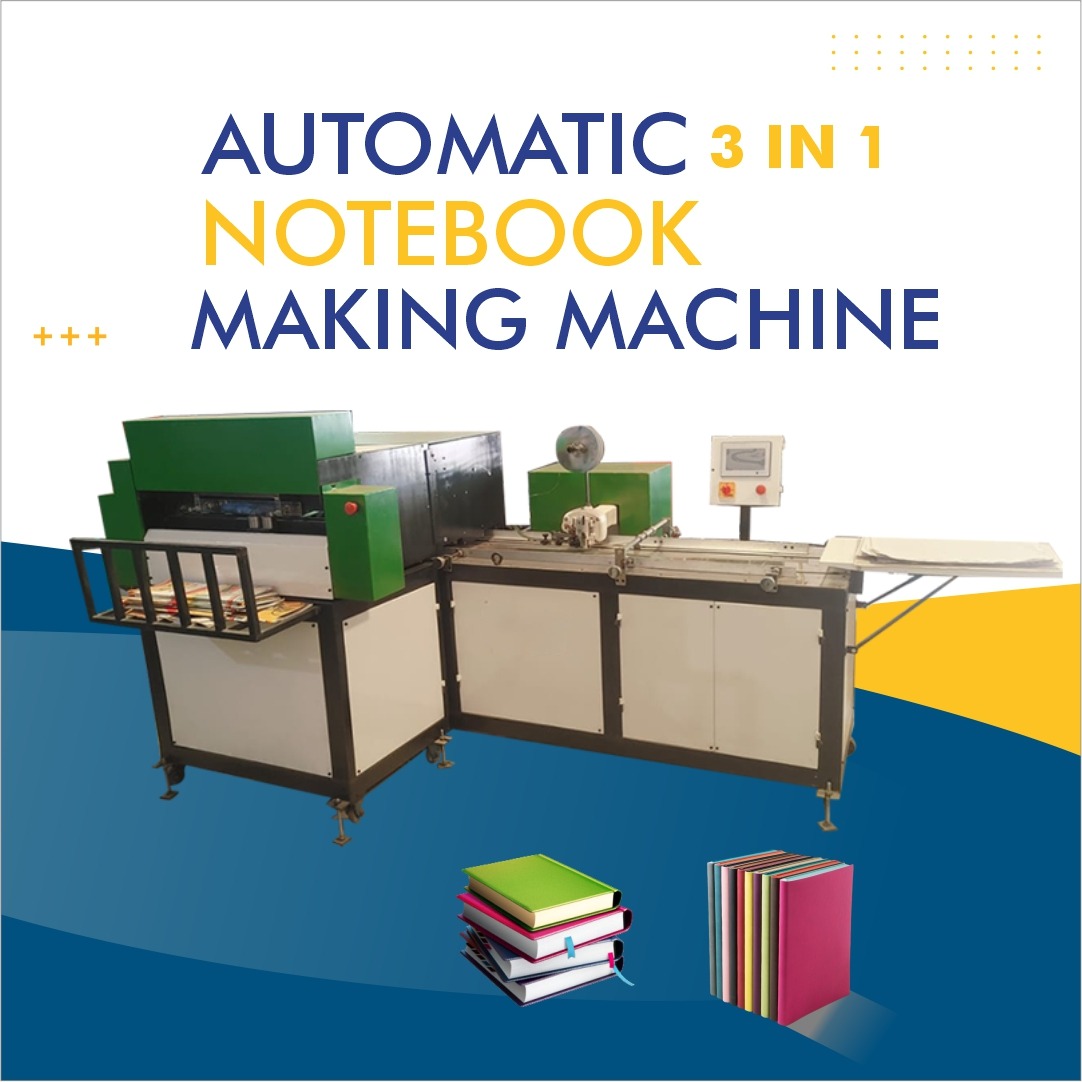

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier in Dibrugarh Assam | Reliable Machines & Support

Notebook Making Machine Supplier in Dibrugarh | Assam

In the heart of Assam, Dibrugarh is emerging as a growing centre for small-scale manufacturing, educational supplies, and printing industries. If you are planning to set up a notebook making machine unit in Dibrugarh or upgrading your existing notebook production line, you will need reliable equipment, local technical support, and compliance with regional requirements. This comprehensive guide will cover everything you need to know — from choosing the right notebook manufacturing machine to sourcing a paper binding machine near you, installation, operations, and after-sales care.

Why Choose Dibrugarh, Assam for Notebook Production

There are several reasons why Dibrugarh is an advantageous location for setting up notebook production:

-

Proximity to raw-material suppliers: paper mills, local pulp & paper sources in Assam and nearby states.

-

Lower logistics costs for North-East India distribution.

-

Growing literacy and educational demand in Assam, Arunachal Pradesh, Nagaland and neighbouring regions.

-

Access to local skilled labour and technicians familiar with printing / binding processes.

Given these advantages, investing in a high-quality notebook making machine here can give you a competitive edge.

Types of Notebook Making Machines

Before you invest, it is important to understand the types of machines available. You may require more than one to complete your process:

-

Paper cutting & trimming machine

-

Cuts large paper sheets to size. Accuracy is critical for notebook aesthetics.

-

-

Folding / Collating machine

-

Automatically folds or arranges signature sheets in sequence.

-

-

Stitching / Sewing machine

-

For bound notebooks using thread sewing or staple binding.

-

-

Spiral binding or comb-binding machine

-

If your product uses spiral coils, this binding equipment is essential.

-

-

Cover lamination / glazing / punching machine

-

Adds finishing touches, laminated covers, punched holes etc.

-

-

Notebook manufacturing machine (combined unit)

-

A more integrated option that carries out multiple steps in one line.

-

Each of these units falls under the broader category of notebook manufacturing equipment or industrial binding machine solutions.

Key Features to Look For

When selecting a notebook making machine, you should evaluate:

-

Capacity – number of notebooks per hour / shift.

-

Paper size compatibility – A4, A5, custom sizes.

-

Binding method – thread-sewn, staple-stitched, spiral bound, glued binding.

-

Automation level – manual, semi-automatic, fully automatic.

-

Power consumption – critical where power backup or generator supply is needed.

-

After-sales support – technician available nearby, spare parts supply in Assam.

-

Warranty & maintenance plan – ideally local service centre or partner agent in Assam.

Supplier Options & Local Support

To ensure reliable procurement, you can consider the following routes:

-

National / Pan-India suppliers

-

Many manufacturers in Delhi, Kolkata or Bangalore supply notebook making machines across India. Ask for dealers in Assam or service partners near Dibrugarh.

-

-

Regional vendors / dealers

-

A dealer located in Assam (or nearby cities like Guwahati) may provide advantages: faster shipping, lower freight charges, local installation teams, and knowledge of Assam’s electrical / regulatory norms.

-

-

Custom setups

-

If you require a bespoke production line, you can combine imported machines and local modifications. Here you will need an engineer / integrator partner in Assam for integrating multiple units.

-

Cost Estimates & Investment

Here are approximate cost considerations for setting up a notebook making machine unit in Dibrugarh:

| Component | Estimated Cost (INR)* | Notes |

|---|---|---|

| Basic stitching / cutting line | 3 – 6 lakh | Semi-automatic machines |

| Semi-automatic spiral binding line | 5 – 10 lakh | Includes binding unit, motor, safety features |

| Fully automated notebook production line | 15 – 25 lakh | Integrated equipment: cutting, folding, binding, finishing |

| Utility costs & installation | 1 – 2 lakh | Electrical wiring, civil modifications, foundation, safety enclosure |

| Maintenance & spares stock | 50,000 – 1 lakh | First-year spares, belts, blades, motor servicing |

* These are indicative values and will vary depending on brand, capacity, shipping charges to Dibrugarh, and import duties (if applicable).

Make sure to request formal quotations from multiple suppliers, including details on delivery lead time and freight charges to Assam.

Regulatory & Operational Considerations

Operating such equipment in Assam (specifically Dibrugarh) may require you to consider:

-

Electricity supply & voltage compatibility: Assam uses 230 V / 50 Hz; confirm machine compatibility and ensure earthing / safety compliance.

-

Factory / industrial license & safety compliance: Local municipal or district authorities may require approvals.

-

Noise & environmental norms: Ensure that your machine’s acoustic emissions comply with regional standards to avoid local complaints.

-

Training & skilled operator availability: Hire or train staff for machine operation, preventive maintenance, and safety procedures.

Benefits of Upgrading to High-Quality Machine

Investing in a modern notebook manufacturing machine (or upgrading your older paper binding machine) can bring multiple advantages:

-

Increased production speed → more notebooks produced daily.

-

Better finishing quality → fewer rejects, better customer satisfaction.

-

Lower manual labour costs → improved margins.

-

Flexibility to offer different binding styles (stitched, spiral etc.).

-

Capability to scale up when demand increases from schools, offices, and institutional orders across Assam and Northeast India.

Case Study / Example Scenario

Imagine you run a small printing firm in Dibrugarh and you currently produce 500 notebooks per day using manual stitching and hand cutting. Demand has increased during the academic season. You decide to install a semi-automatic notebook making machine line that includes a cutting-folding unit and stitching binder.

-

After installation, your capacity increases to 2,000 notebooks/day.

-

Labour cost per notebook drops.

-

Delivery time to educational institutions in Tinsukia, Sivasagar or across Upper Assam improves.

-

Profit margin improves by ~15 %.

Over the first year, you recover your investment through higher throughput and lower waste / rejects. Then you expand to offer spiral bound variants using additional binding equipment.

How to Procure & What to Ask Suppliers

Use this checklist when requesting quotes:

-

Machine model & brand

-

Throughput (notebooks per hour)

-

Binding type(s) supported

-

Dimensions & footprint (will it fit your available space in Dibrugarh workshop?)

-

Power rating & electrical compatibility

-

Delivery & installation timeline (including freight to Assam)

-

Training & commissioning support on-site in Dibrugarh

-

Spare parts access inside Assam (Guwahati / Dibrugarh region)

-

Warranty terms & preventive maintenance contracts

-

Optional attachments or upgrades (lamination, cover punching / gloss finishing)

Maintenance & After-Sales Support

To ensure minimal downtime, consider these maintenance best practices:

-

Schedule preventive maintenance: belt replacement, lubrication, blade sharpening.

-

Keep a small inventory of critical spare parts locally (cutting blades, motor belts, binding coils / staples).

-

Train at least two operators on basic maintenance tasks.

-

Establish a service contract with your supplier or local technical partner.

-

Document machine usage hours and periodic inspection logs — particularly important if you scale up your capacity.

Marketing Your Notebook Production Business

Once your machinery is operational, you can use these marketing strategies to grow orders in Dibrugarh and the region:

-

Approach schools & coaching centres in Assam & neighboring states for supply contracts.

-

Offer customized notebooks (printed covers, branded exercise books) for local academies.

-

List your business in local industrial directories under “notebook manufacturer Assam / stationery supplier Assam”.

-

Maintain quality certificates or samples to show binding strength, paper finish, and durability.

-

Provide timely delivery services to Upper Assam districts such as Tinsukia, Sivasagar, Duliajan, Dhemaji etc.

Challenges & Risk Mitigation

Some potential challenges and how to tackle them:

| Challenge | Mitigation |

|---|---|

| Power fluctuations / outages | Use stabilizers, UPS or backup generator for sensitive binding / cutting units |

| Raw-material price fluctuations | Negotiate long-term contracts with local paper suppliers |

| Demand seasonality | Scale operations during academic seasons; diversify into notebooks for coaching institutes, libraries, or custom printing |

| Transportation delays to remote locations | Plan logistics partnerships for reliable distribution within Assam and upstream to neighbouring states |

Conclusion

To summarise, investing in a reliable notebook making machine in Dibrugarh, Assam offers strong potential if you plan carefully. By selecting the right notebook manufacturing machine, ensuring local technical support, and aligning with regional demand patterns, you can build a sustainable and scalable notebook production business.