Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

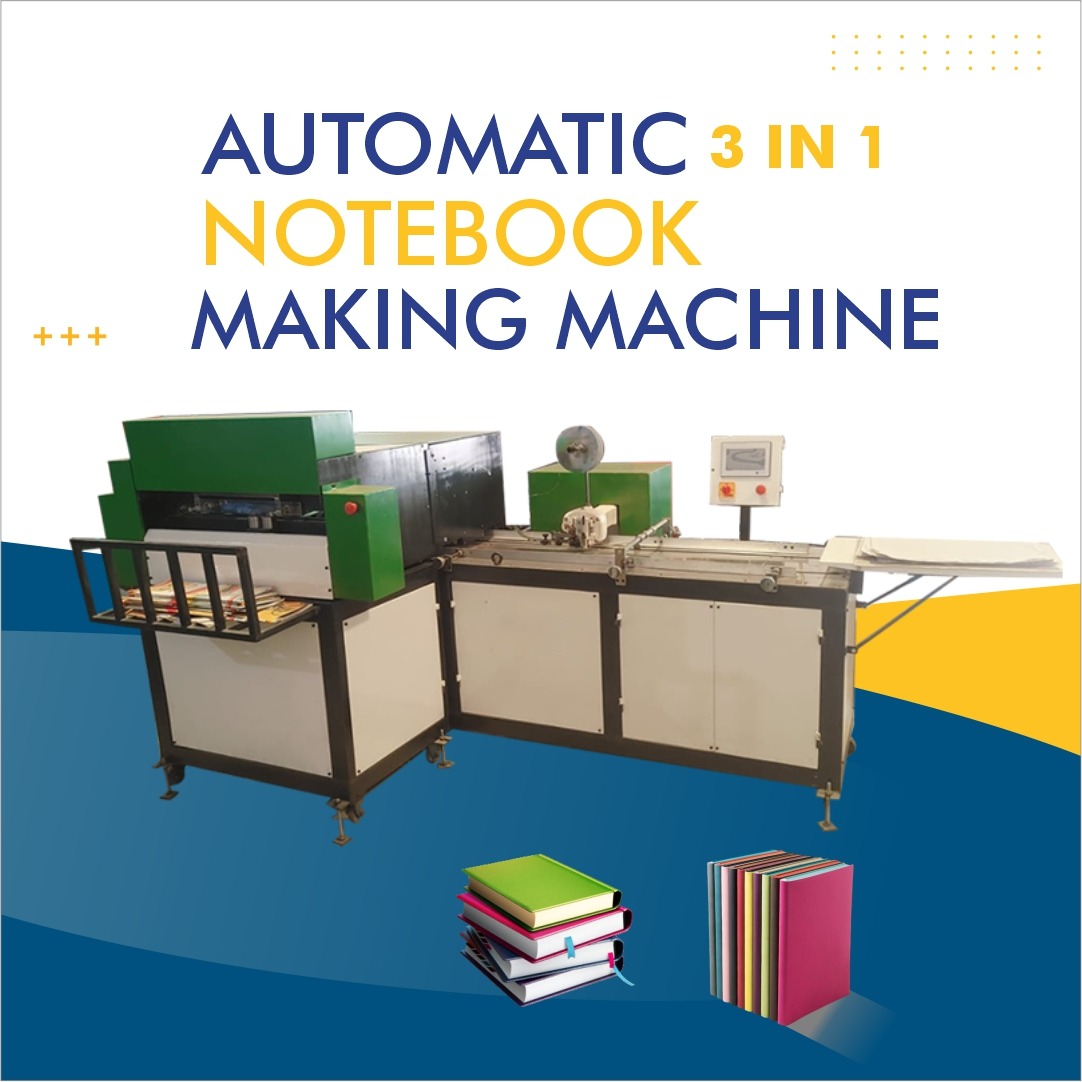

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Dhubri Assam | Automatic School / College Notebook Maker

Notebook Making Machine Dhubri | Assam

If you are looking for a reliable notebook making machine in Dhubri, Assam, you have come to the right place. A notebook making machine (also known as a notebook production machine or notebook maker) is an essential piece of equipment to manufacture school, college or corporate notebooks in-house or as a business. Whether you want to start a small-scale stationery unit, expand production capacity, or upgrade from a manual system to an automated one, an automatic notebook maker can help you improve speed, consistency and quality.

In this guide, we discuss how to select the right notebook making machine, its benefits, local suppliers near Dhubri Assam, key specifications, pricing factors, after-sales support, and everything you need to start producing notebooks efficiently.

Why Choose a Notebook Making Machine in Dhubri, Assam?

Proximity and Support

Having a machine supplier located near Dhubri Assam offers significant advantages. Lower logistics cost, faster shipping, on-site installation and timely maintenance are all easier when your machine comes from a supplier familiar with the local area. Local vendors may also help you with regulatory compliance and advice on power and infrastructure in Assam.

Growing Demand for Notebooks

Assam has a strong demand for notebooks across schools, colleges and tutoring institutes. Producing notebooks locally reduces your dependence on imports or distant suppliers, lowers your lead time, and offers faster turnaround for custom specifications such as cover design, page count, binding style, and paper quality.

Cost-Effectiveness

By investing in a notebook making machine close to your location, you reduce freight charges and customs delays. You may also benefit from local tax or subsidy schemes available in Assam or under state-level entrepreneurship schemes. These advantages can improve your return on investment.

Types of Notebook Making Machines

When you search for a “notebook making machine”, you will find multiple types. Understanding the differences helps you choose the right one for your capacity and budget.

-

Manual Notebook Maker

Basic, low-cost machines with manual feeding or hand-operated binding. Suitable for very small volume production or trial runs. -

Semi-Automatic Notebook Making Machine

These offer automatic feeding or binding partially, but require operator input at some stages. Ideal when you want to reduce labour but retain some human oversight. -

Fully Automatic Notebook Making Machine

In this model, pages are cut, collated, pressed, stitched or glued, and trimmed automatically without manual intervention. It offers high-speed, high consistency, and is well-suited for industrial-level output. -

High-Speed Continuous Notebook Maker

Designed for large volumes and minimal downtime. Excellent for commercial production units aiming to serve district-wide or regional stationery markets. -

Notebook Binding Machine as part of Full Line

Some setups include binding, trimming, cover-laminating, erasing edges, and punching for spiral or stitching binding. These are more complex but provide end-to-end notebook production.

Each variant has pros and cons in terms of cost, speed, maintenance, operator skill requirement, and space.

Key Specifications and Features to Evaluate

To make a smart purchase, here are the technical specifications and features you should evaluate:

-

Production speed (notebooks per minute or per hour)

-

Page count capacity (e.g. 16 pages, 32 pages, 64 pages per notebook)

-

Maximum sheet size (A4, letter size, custom dimensions)

-

Cover thickness and material handling

-

Binding type (stitching / stapling / glue binding / spiral)

-

Trimming margin tolerance and precision

-

Power consumption and electrical compatibility with Assam power supply standards

-

Automation level (manual effort required vs automatic feeding and ejection)

-

Footprint and floor space requirement

-

Safety features and ease of maintenance

-

Availability of spare parts locally in Assam or nearby states

-

Local technical support or service contract

A machine with high throughput and automation will cost more initially but will deliver cost savings in labour, reduced waste and higher output in the long run.

Estimating the Investment

When you consider buying a notebook making machine near Dhubri, Assam, the price depends on:

-

Automation level – fully automatic machines cost more than semi-automatic or manual versions.

-

Output capacity – higher speed and volume machines have more robust motors, precision parts, and may require larger infrastructure.

-

Brand and Build Quality – imported or international-standard machines may have premium pricing, while domestic models may offer better value for local markets.

-

After-Sales Support and Local Servicing – machines with warranty, spare-part availability and training support in Assam often command higher price but reduce downtime risk.

-

Custom Features – such as cover embossing, multiple binding styles, or custom sizes.

For example, a semi-automatic notebook making machine might cost somewhere in the mid-range depending on speed, while a fully automatic high-speed model may run into higher investment figures. You should also budget for installation, operator training, power-conditioning (stabiliser or transformer, if needed), and any civil work.

Choosing a Supplier in Dhubri / Assam

When evaluating suppliers near Dhubri, consider these points:

-

Reputation and past installations in Assam or Northeast India

-

Ability to provide on-site installation at your facility

-

Existing customer testimonials or machine units operating in Assam

-

Spare parts availability either in Assam or via a distributor in a nearby city (Guwahati or other urban centres)

-

Warranty terms and preventive maintenance contract

-

Training for operators and technicians

-

Technical compliance with Assam electricity supply (voltage stabilisation, safety standards)

You may start by contacting suppliers in Guwahati or industrial hubs around Assam, who may provide delivery and service to Dhubri district. Ask for sample production runs, site visit references, and possibly trial demonstrations.

Benefits of Using a Notebook Making Machine

Using an automated or semi-automated machine to produce notebooks offers many advantages:

-

Consistent Quality: Precise trimming, alignment, and binding ensure every notebook looks uniform.

-

Higher Throughput: Automation reduces manual time per notebook and increases daily output.

-

Lower Labour Costs: Reduced manual effort means fewer skilled operators needed for production.

-

Faster Turnaround: You can respond to large orders quickly during school season peaks.

-

Customisation Flexibility: Ability to vary page count, cover design, binding styles, and special features such as perforation or hole-punching.

-

Reduced Waste: Automated trimming and collation minimise misaligned pages or bad binding, reducing rejects.

Over time, the productivity gains typically justify the investment for small business owners, stationery manufacturers, or educational cooperatives in and around Dhubri.

Steps to Start Notebook Production in Dhubri

If you plan to begin manufacturing notebooks locally in Dhubri, here are the essential steps:

-

Market Research

Assess demand among schools, colleges, tuition centres and shops in Dhubri district. Identify preferred sizes, layouts (lined, unlined, grid), and quantity. -

Business Plan and Budgeting

Prepare a plan including capital expenditure for notebook making machine, raw materials (paper sheets, cover board, binding staples or glue), labour cost, utilities, premises and marketing. -

Location and Setup

Choose a suitable facility with adequate space, ventilation, wiring and power capacity. Ensure you comply with Assam local regulations for industrial units or home-based production. -

Select Machine and Supplier

Compare quotes from different suppliers, check sample outputs and references. Ensure delivery to Dhubri, electrical compatibility and maintenance terms. -

Raw Material Sourcing

Paper and cover board must be procured locally or from nearby cities. Ensure consistent supply and quality to support your production volume. -

Installation, Testing and Training

Once the notebook making machine is delivered, schedule installation and operator training. Carry out test production runs and quality checks. -

Quality Assurance and Branding

Design your covers with school or region-specific branding. Perform sample tests for durability, binding strength, and finish quality. Use packaging or wrapping for finished notebooks. -

Distribution and Sales

Build relationships with local stationery shops, school boards, tuition centres and government procurement departments. Offer bulk rates or customised features (logo printing, special paper). -

Maintenance & Spare-Parts Management

Keep records of maintenance schedules, order spare parts ahead of time. Local technical support will be critical for downtime reduction.

Local Considerations Specific to Dhubri, Assam

-

Power Supply and Voltage Stabilisation: Rural or semi-urban areas in Assam may have voltage fluctuations. A notebook making machine may require stabilisers or uninterrupted power backup.

-

Transport and Access: Dhubri is located in western Assam near the India–Bangladesh border. Logistics routes should be planned carefully; river routes or road access may affect delivery time and cost.

-

Skilled Labour Availability: Hiring staff trained in operating mechanical equipment or binding machines may require training. Partnership with local technical institutes or vocational centres helps.

-

Climate Effects: Assam’s humidity may affect paper quality, storage of raw sheets and machine rust-proofing. Choose machines with protective coatings or plan for dehumidified storage space.

-

Regulatory Compliance: Ensure you comply with local safety and industrial norms under Assam state regulations and any permits required for small-scale manufacturing units.

Case Example (Hypothetical)

Suppose you establish a small stationery manufacturing unit in Dhubri with a semi-automatic high-speed notebook making machine capable of producing 1,000 notebooks per day. You install a machine worth ₹ X lakhs with local supplier support in Assam.

-

Fixed cost (machine + installation + training): ₹ X lakh

-

Operating cost (labour, electricity, raw materials) per notebook: ₹ Y

-

Sale price to schools / retailers per notebook: ₹ Z

Over a full academic season of six months, you generate volume sales to nearby schools and tuition centres. Because your machine is local, you save on freight and downtime compared to importing from far away. After two seasons, you recover your investment and generate steady profit.

You then add another binding feature (perhaps spiral binding or custom cover printing) and expand your clientele to neighbouring districts beyond Dhubri.

Synonyms and Repeated Keywords Usage

To reinforce SEO ranking for related searches, the following synonyms are also used regularly:

-

Notebook production machine

-

Automatic notebook maker

-

Notebook manufacturing equipment

-

Notebook binder machine

-

Stationery manufacturing machine

Each of these terms is used through the content to improve discoverability for similar search queries.

Conclusion

Investing in a notebook making machine in Dhubri, Assam can help you establish or expand a stationery manufacturing venture with consistency, scalability and cost-efficiency. By choosing the right machine type, specifications, automation level, and supplier support, you can build a competitive business serving the local educational market.