Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

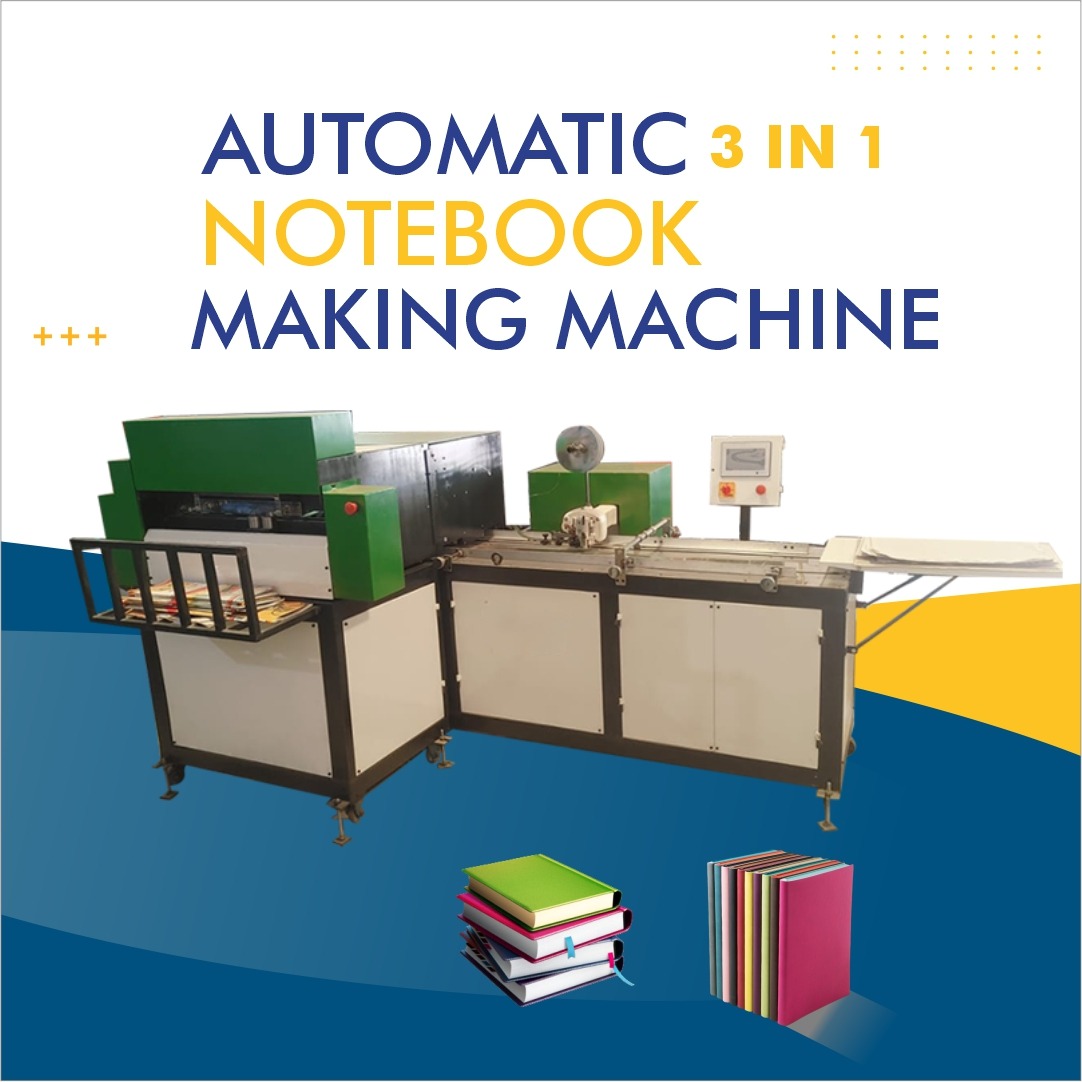

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Vilasipara Assam – Supplier, Price & Setup Guide

Notebook Making Machine Vilasipara | Assam

If you are planning to set up a notebook manufacturing business in or near Vilasipara, Assam, choosing the right notebook making machine is a critical first step. Whether you want a manual, semi-automatic, or fully automatic machine, understanding the features, price range, supplier network, and installation support will influence your success. In this guide we cover types of machines, cost, supplier options around Assam, and practical advice for running a small or medium scale notebook unit in Vilasipara.

This content includes repeated usage of notebook making machine and related synonyms to help in search engine ranking.

Market & Location Context: Vilasipara / Assam

-

Assam has a growing demand for stationery and education-related products. Setting up manufacturing closer to raw material sources and within the state can reduce logistics cost and improve turnaround time.

-

While Vilasipara may not yet host many large scale machine suppliers, nearby cities like Guwahati serve as hubs for sourcing equipment, spare parts, and technical support.

-

Many suppliers list their machines under “Assam / Guwahati / Northeast India” which means they may deliver or support installations around Vilasipara. For example, Laghu Udyog offers notebook making machines across Assam including rural areas. Laghu Udyog

-

Also several wholesalers or machine dealers in Guwahati (e.g. Khanapara) list notebook making machines. Justdial+1

Because of your location in Rāni Khera / Delhi zone though, you may want shipping routes, freight costs, and local labour availability to be considered if you bring machines via Guwahati or import them.

Types of Notebook Making Machines

When purchasing a notebook making machine, you need to decide on the level of automation and capacity. Below are common categories:

| Type | Description | Use-Case |

|---|---|---|

| Manual Notebook Making Machine | Fully manual processes for cutting, ruling, folding, stitching / binding. Suitable for very small scale or startup units. | Low investment, high labour, limited throughput. |

| Semi-Automatic Notebook Making Machine | Some steps automated (eg cutting, stitching), others manual. Better throughput with moderate cost. | Small‐to-medium scale manufacturing in Vilasipara or nearby towns. |

| Automatic / Fully Automatic Notebook Making Machine | Most steps automated (cutting, ruling, stitching, trimming, binding). High speed, consistent results. | More capital investment but higher output, less manual dependence. |

Each of these options has pros and cons:

-

Manual machines cost less initially, are easier to repair, and may require less technical support — useful for testing product lines or custom notebooks.

-

Semi-automatic machines hit a middle ground: you get better consistency, somewhat higher capacity, and still manageable maintenance.

-

Automatic machines offer best speed and lower labour cost per unit in the long run, but require more capital, technical expertise, maintenance, and sometimes more reliable electricity/facilities.

Examples: some manual notebook making machines (SBS brand) offer production up to ~3,000 notebooks per day; price may range in lakhs of rupees for full setup. sbsmachine.com

Another example: fully automatic models in Assam / Guwahati area listed via ExportersIndia cost in the high Lakhs to multiple Lakhs range. ExportersIndia+1

Cost & Price Ranges

Here’s an overview of typical price ranges in India / Assam region you can expect when buying a notebook making machine:

| Machine Type | Indicative Price Range* | Notes |

|---|---|---|

| Manual Notebook Making Machine / Basic Setup | Rs 1.5 lakh to Rs 3 lakh | Low capacity versions, may require manual binding or finishing. |

| Semi-Automatic Notebook Making Machine | ~Rs 2-6 lakh depending on capacity & features | Includes automated cutting or stitching, moderate throughput. |

| Fully Automatic Notebook Making Machine | Rs 6 lakh to Rs 15 lakh or more | High speed models with greater output, more advanced features. |

| Specialized or high capacity machines | Up to Rs 10-13 lakh or more for premium equipment | For example, some fully automatic models may exceed Rs 10 lakh. sbsmachine.com+1 |

*Prices vary widely based on capacity (units per hour/day), automation grade, brand, power requirements, and delivery / installation costs near Vilasipara.

Also consider additional costs: shipping / freight from Guwahati or supplier location; installation charges; civil foundation or power upgrades; labour training; spare parts & maintenance.

Choosing the Right Vendor / Supplier

When procuring a notebook manufacturing machine, consider the following factors:

-

Proximity & After-Sales Support

Since Vilasipara is rural or semi-rural in Assam, choosing a supplier that can deliver, install, and service your machine locally is valuable. Suppliers based in Guwahati, or firms that explicitly support Assam (e.g. Laghu Udyog) may offer faster support. Laghu Udyog+1 -

Capacity & Throughput Requirements

Estimate how many notebooks you plan to produce per day or month. For small-scale, manual or semi-automatic may suffice; for growth, plan for capacity headroom. -

Power / Infrastructure

Automatic machines may need stable power supply (3-phase or high voltage), space for installation, dust management and raw material feeding (paper sheets, covers, binding materials). Check whether your building in Vilasipara can meet electrical / structural requirements. -

Raw Material & Labour Availability

Ensure local availability of paper sheets, binding thread / staples, cover material etc. Also ensure that you have trained operators or can hire labour to run stitching, trimming, ruling, finishing. -

Maintenance & Spare Parts

Machines with local support or suppliers with spare-parts inventory (in Assam / Guwahati region) will reduce downtime. Check guarantee / warranty terms. -

Cost vs ROI Assessment

Calculate return on investment: cost of machine + installation + input materials + labour / power — divided by revenue from selling notebooks. For a startup unit based near Vilasipara, ensure that demand (schools, stationery shops, local markets) can absorb your production, or plan for distribution to nearby towns. -

Licence / Regulatory / Quality Standards

In some cases you may require permits for commercial manufacturing, paying GST, quality checks. For notebooks used in schools, ensure paper-gramme standards, ruling standards, binding quality, cover finishing etc.

Setting Up a Notebook Making Unit in Vilasipara

Here is a step-by-step approach you can follow:

-

Market Survey & Demand Estimation

Survey nearby schools, stationery shops, local markets (Vilasipara, nearby towns) to estimate demand for notebooks (exercise books, custom ruled notebooks, size formats). -

Select Machine Type & Capacity

Based on demand estimate, choose if you want manual / semi-automatic / fully automatic machine. Estimate initial volume, growth plan. -

Procure Machine

Contact suppliers in Guwahati / Assam (for example via directories like Justdial, ExportersIndia, Aajjo etc). Request quotations including freight to Vilasipara, installation cost, training. -

Location & Infrastructure Preparation

Prepare a small shed or factory-room: ensure stable power supply, ventilation, table / storage space for raw material & finished notebooks. Ensure safety (machine guarding, operator training). -

Raw Material Sourcing

Arrange supply for paper sheets, binding material (thread, staples), cover boards / cover paper, ruling / printing ink if applicable. Local paper mills or paper dealers in Assam may help reduce cost. -

Labour / Staff

Hire / train staff for operation of machine, quality control, packaging. Allocate space for finishing, trimming, bundling & packing for local sale or distribution. -

Production » Quality Control » Packaging

Implement checks for ruling accuracy, stitch / binding strength, trimming / edge finishing, cover durability. Package notebooks in bundles for retail sale. Develop brand / label / packaging. -

Marketing & Sales

Approach local stationery shops, school contracts, direct sale in local markets. Also consider online sales or nearby larger towns (Guwahati, etc). -

Maintenance & Scaling

Keep spare parts and basic tools. Maintain logs for breakdowns. Evaluate performance monthly and plan for capacity expansion (e.g. adding additional machine later).

Benefits of Locating in Vilasipara / Assam

-

Lower land / rental cost compared to metropolitan areas.

-

Potentially lower labour cost and proximity to local markets.

-

Support from state / local policies for small & medium enterprises (SMEs) or rural industrial development (you may investigate Assam government schemes for “Laghu Udyog / MSME / Startup assistance”).

-

Opportunity to scale to supplying not only local demand but neighbouring districts.

Also using an efficient notebook production machine can allow you to develop custom notebook products (different sizes, ruling styles, cover designs), which may help differentiate your business in the marketplace.

Risks & Mitigation

While the opportunity is promising, you should plan for certain risks:

-

Machine breakdowns or downtime without local support

-

Fluctuation in raw material price (paper cost, binding material)

-

Electricity supply instability in rural or semi-rural Assam

-

Competition from imported or cheaper notebooks from outside Assam

-

Quality compliance (durability, safety of binding, finishing).

Mitigation strategies include: maintaining a buffer stock of raw materials, periodic maintenance schedule, sourcing a trusted supplier with warranty / service, and building local relationships with schools & bulk buyers.

Conclusion

Setting up a notebook manufacturing unit in or near Vilasipara, Assam is definitely feasible if you select the right notebook making machine, plan capacity carefully, ensure infrastructure, and establish supply chain links. Whether you begin with a manual or semi-automatic machine and grow gradually, or invest in a fully automatic system from the start, attention to local support, cost vs ROI, and quality will be key.