Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

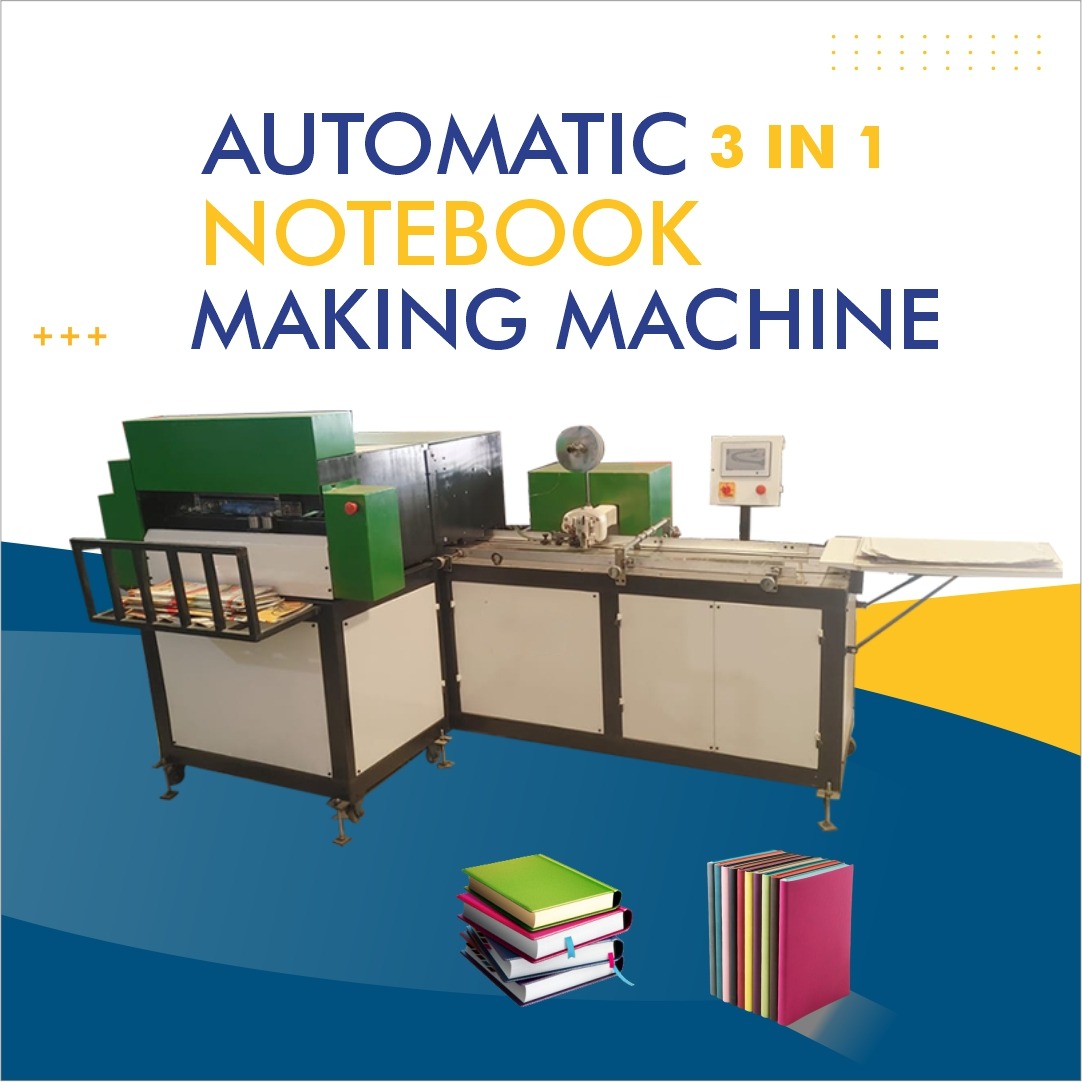

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Ziro | Automatic & Semi-Automatic Notebook Machinery Arunachal Pradesh

Notebook Making Machine in Ziro | Arunachal Pradesh

If you are setting up or expanding a notebook manufacturing unit in Ziro, Arunachal Pradesh, choosing the right notebook making machine is critical. Whether your requirement is for automatic notebook maker or semi-automatic systems, your investment must deliver quality output, reliable performance, minimal downtime, and adaptability to various sizes. This guide explains everything you need to know — features, variants, selection criteria, benefits, local considerations, and how to procure notebook manufacturing machinery in Ziro.

Why Ziro, Arunachal Pradesh is the Right Location

-

Ziro is an emerging hub in Arunachal Pradesh with increasing industrial activity.

-

Suppliers list shows multiple notebook making machine models listed for Ziro on machinery-supplier directories. aajjo.com

-

Transport routes within Arunachal Pradesh and northeastern markets may benefit from a local manufacturing setup.

-

Local demand for educational stationery (schools, colleges) supports investment in notebook production equipment.

Types of Notebook Making Machines

When you search for notebook making machines, you will encounter several categories. It helps to understand which suits your needs:

-

Manual Notebook Making Machine

-

Requires human operation for cutting, folding, stitching or binding.

-

Lower initial cost.

-

Suitable for low-volume production, bespoke sizes, or prototyping.

-

-

Semi-Automatic Notebook Machine

-

Automates certain stages such as stitching, pinning, folding or trimming.

-

Requires manual feeding or occasional operator intervention.

-

Balances cost vs productivity.

-

-

Automatic Notebook Making Machine

-

Fully automated workflow: cutting, stitching / binding / folding / squaring in a unified line.

-

Higher throughput (hundreds to thousands of notebooks per hour).

-

Ideal for medium to large scale production.

-

-

3-in-1 or Multi-Function Machinery

-

Combines cutting, stitching & folding or trimming & squaring in one integrated system.

-

Reduces labor, increases uniformity & quality.

-

-

Notebook Pinning & Folding Machines

-

Specialized for stapling or pinning the edges, folding and squaring sheets.

-

Key Features to Compare

When procuring a notebook manufacturing machine, check these important specifications:

-

Automation Grade: Manual / Semi-automatic / Fully automatic.

-

Production Capacity: Number of notebooks per hour or per minute.

-

Maximum Notebook Thickness: Capability to stitch or bind thick notebooks.

-

Sheet Size Compatibility: A4, A5, custom sizes.

-

Cutting Size or Blade Width: Maximum width of sheet/cutting blade.

-

Power & Phase: Single-phase or three-phase electrical supply.

-

Mechanical Build: Body material (mild steel / stainless), frame rigidity.

-

Speed & Accuracy: Stitching speed, fold precision, trim quality.

-

After-Sales Service & Spare Parts Availability: Especially important in remote locations like Ziro.

-

Compliance & Certifications: Quality standards, local regulations, safety features.

Benefits of Investing in Notebook Making Machinery

-

Cost Efficiency & Scale: Moving from manual to semi or fully automatic systems increases throughput and reduces labor cost per unit.

-

Consistency & Quality: Automated systems maintain uniform binding, edge trimming, fold alignment.

-

Flexibility: Machines that handle multiple sizes/formats allow you to produce exercise notebooks, school notebooks, custom bound notebooks as required.

-

Market Advantage: Having in-house notebook production helps you respond quickly to orders for schools, coaching institutions, local distributors in Arunachal Pradesh.

-

Return on Investment: High-quality machines with good uptime and low maintenance can recover costs over months through volume production.

Challenges & Considerations Specific to Ziro / Arunachal Pradesh

While Ziro offers opportunities, there are a few local considerations:

-

Logistics & Transportation: Moving large machinery to remote hill-terrain areas can incur extra cost. Ensure the supplier supports delivery & installation in Ziro.

-

Power Supply Variability: Ensure selected machine supports local phase/power supply conditions (voltage stability, single vs three-phase).

-

Spare Parts & Maintenance: Verify that periodic maintenance service or spare-parts availability is feasible within Arunachal Pradesh, or that the supplier provides support.

-

Training & Operator Skills: Semi or full automatic machinery may require trained operators. Plan for training, staffing & possibly remote/manual assistance.

-

Regulatory & Local Permissions: Local bodies or industrial development authorities may have rules for setting up manufacturing units. Ensure compliance with any local licensing.

How to Select a Supplier in Ziro

To procure a notebook making machine locally or regionally, you can follow these steps:

-

Requirement Assessment

-

Estimate your monthly or yearly notebook production volume.

-

Define formats (size, thickness, binding style).

-

Determine level of automation desired (manual / semi / full).

-

-

Shortlisting Suppliers

-

Check directories / platforms listing machinery in Ziro or Arunachal Pradesh. For example, there are listings of models available in Ziro on Aajjo platform. aajjo.com

-

Compare multiple models: cost, features, brand reliability, user reviews.

-

-

Requesting Quotations

-

Ask for detailed quotations including machine price, shipping to Ziro, installation charges, training, maintenance contract.

-

Verify warranty, quality assurance & after-sales service arrangements.

-

-

Site Visit / Demonstration

-

If possible, visit a demonstration unit or request video / factory demonstration.

-

Test sample notebooks for binding quality, trimming precision, fold alignment.

-

-

Procurement & Installation

-

Confirm electrical compatibility (voltage / phase).

-

Ensure civil foundation or structural support at your workshop.

-

Arrange for training of operators and preventive maintenance planning.

-

-

Monitoring & Optimization

-

After commissioning, monitor output rate, rejection rate (defective notebooks), downtime.

-

Work with the supplier to optimize settings (stitching pressure, fold angle, trimming speed) to minimize waste.

-

Case Example / Scenario (Hypothetical)

Suppose you plan to produce 5,000 school notebooks per month with A4 size, up to 80 pages, stitched binding. You expect to upgrade from manual binding to semi-automatic stitching & trimming.

-

You review a semi-automatic notebook making machine in Ziro. It offers capacity ~800 notebooks per hour, accepts sheet size up to A4, thickness 5–8 mm.

-

Quotation shows price ₹ 3,50,000 (including shipping & installation).

-

After installation, monthly output meets requirement with margin for increase; labor cost reduces; quality improves.

-

Within 12-18 months, ROI is achieved compared to manual labor & external outsourcing.

This demonstrates how local availability of notebook manufacturing machinery in Ziro can support small to medium scale notebook production units in Arunachal Pradesh.

Maintenance & Operational Best Practices

Once you install your notebook making machine, adopt best practices to prolong lifespan & ensure consistent quality:

-

Schedule preventive maintenance: lubricate sliding parts, check blade sharpness, tighten fasteners.

-

Monitor wear on stitching pins, fold rollers, trimming blades; arrange for spare parts order ahead of time.

-

Regular calibration: align fold, trimming squaring, ensure binding margins.

-

Train operators in safety procedures, machine guards, emergency stop handling.

-

Keep log of machine runtime, downtime, maintenance activities — helps in planning service intervals or upgrades.

Scaling Up & Diversification

Once your initial notebook production is stable, you can consider scaling up:

-

Move from semi-automatic to fully-automatic systems to increase throughput.

-

Add complementary machinery: e.g. paper cutting machine, lamination or hard-cover binding equipment.

-

Offer custom notebook formats: spiral binding, cork covers, specialty paper.

-

Target nearby markets: other districts in Arunachal Pradesh, Assam, Sikkim or Northeast region.

Conclusion

Investing in a notebook making machine in Ziro, Arunachal Pradesh provides a strategic opportunity to establish or enhance notebook production capacity with local advantages. By choosing the right automation level, selecting reliable machinery, planning maintenance & operation carefully, you can build a competitive notebook manufacturing setup serving schools, institutions & retailers across the region.