Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

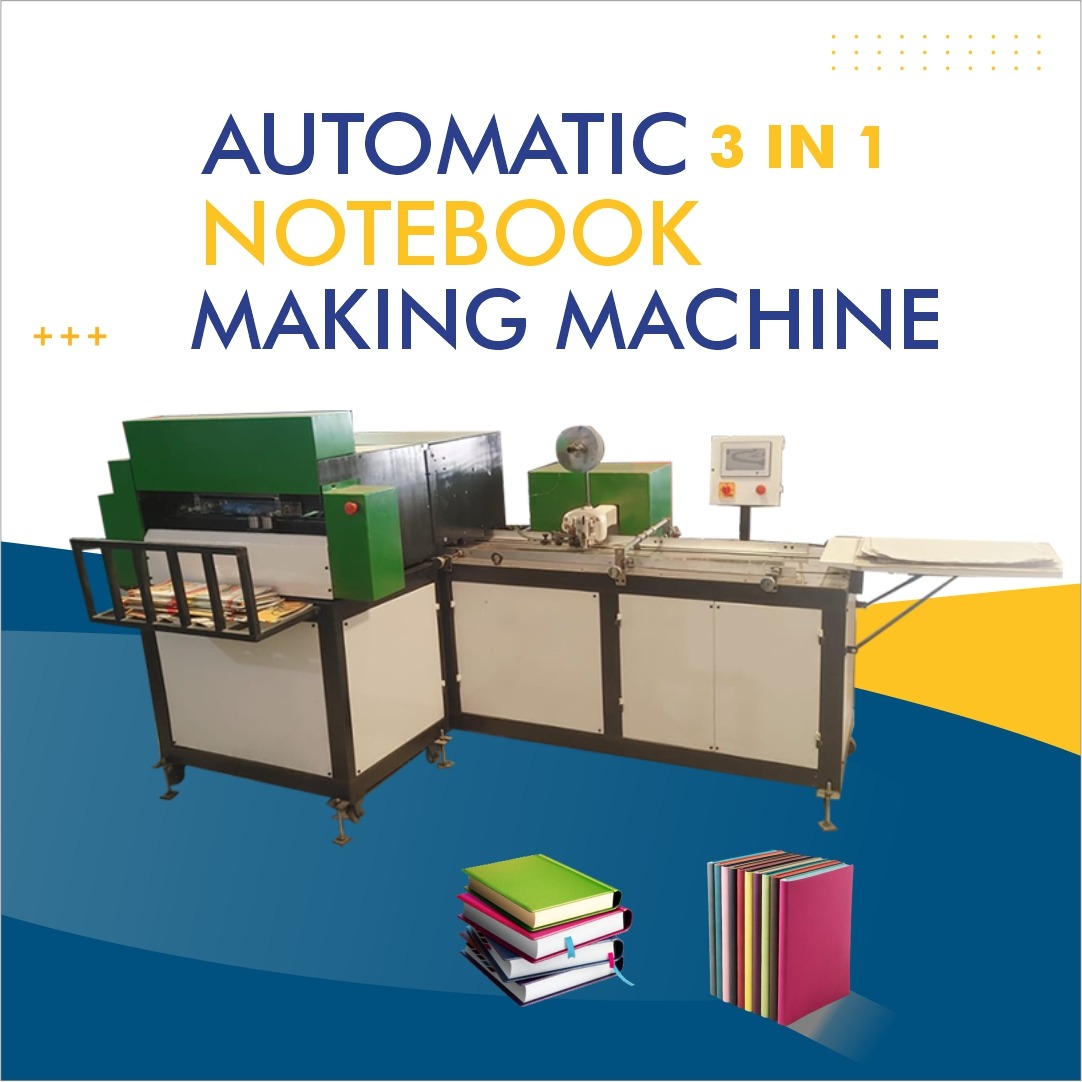

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine – Supplier & Manufacturer in Yingkiong, Arunachal Pradesh

Notebook Making Machine in Yingkiong | Arunachal Pradesh

In the scenic region of Yingkiong, Arunachal Pradesh, entrepreneurs and small-scale manufacturers are increasingly looking to set up local stationery production units. One of the most essential investments for producing notebooks is a notebook making machine. Whether you’re aiming to manufacture notepads, school exercise books, spiral notebooks or customized journals, having the right machinery ensures efficient production, consistent quality, and economic viability.

In this comprehensive guide, we cover everything you need to know about notebook making machines in Yingkiong, Arunachal Pradesh — from features and types to setup, local benefits, sourcing, installation, operation, and maintenance.

We will also explore key considerations when choosing notebook manufacturing equipment, and how having operations in Arunachal Pradesh gives you strategic advantages.

Why Choose Yingkiong, Arunachal Pradesh for Notebook Manufacturing?

Local Advantage and Logistics

-

Yingkiong is a town in the Upper Siang district of Arunachal Pradesh, offering potential access to local raw materials (paper, binding supplies, packaging).

-

Being closer to rural markets and schools gives you demand linkages for stationery products.

-

State initiatives and central schemes may support small industries and MSMEs (Micro, Small & Medium Enterprises) in remote or hilly areas.

Strategic Opportunity

-

Many parts of Arunachal Pradesh are under-served for stationery manufacturing. Setting up your own machinery here reduces transportation cost, delays, and supply chain dependencies.

-

Local manufacturing also helps you tap into government tenders for schools and educational institutions across North-East India.

Incentives & Local Support

-

You may benefit from state government incentives, subsidies or tax relief under the MSME or “Industry in Border or Hill Areas” schemes.

-

Local workforce can be trained for machine operation, reducing labor cost and helping social development.

With these advantages, installing a good notebook manufacturing machine in Yingkiong becomes an ideal business initiative for aspiring entrepreneurs.

Types of Notebook Making Machines & Equipment

To select the right machine for your setup, it’s important to understand the different types and functions:

-

Automatic Notebook Making Machine

-

Designed to perform multiple steps (cutting, binding, stitching, trimming) with minimal human intervention.

-

Ideal for medium-to-large scale production. Offers higher throughput and consistency.

-

-

Semi-Automatic Notebook Maker

-

Some manual involvement required, but combines automated feeding, cutting or trimming steps.

-

Suitable for smaller production volumes, or startups.

-

-

Manual Notebook Cutter / Binding Equipment

-

Basic machines for cutting paper to size, trimming edges, and simple binding methods such as saddle-stitching or hand-binding.

-

Lower capital cost; suited for very small-scale or pilot production.

-

-

Book Binding Machine (Edge Binding / Spiral Binding / Thread Sewn Binding)

-

For finishing operations: punching holes, inserting spiral wire, or stitching binding.

-

Complements cutting and stacking operations in notebook production line.

-

-

Spiral & Wire Binding Unit

-

If you intend to make spiral-bound notebooks, this unit helps coil insertion and trimming of binding edge.

-

-

Notebook Cutting and Trimming Machine

-

Precise guillotine cutters or trimming machines to finish edges cleanly and uniformly.

-

Each of these equipment types plays a vital role in the notebook manufacturing equipment inventory. Your choice depends on production scale, available capital, and design variety.

Key Features You Should Look For

When selecting a notebook making machine, consider the following critical features:

-

Production Capacity: Units per hour or per day. For example, can it produce 200 notebooks per hour or 1000 per shift?

-

Size & Format Range: Supports various dimensions (e.g. A4, A5, custom sizes).

-

Binding Method Compatibility: Stitching, glue binding, wire or spiral binding.

-

Cutting Precision: Clean trimming with minimal wastage.

-

Automation & Control System: Digital controls, safety guards, error detection.

-

Power Requirements & Efficiency: Given remote hilly connectivity, machines with lower energy consumption and correct voltage compatibility are preferred.

-

Maintenance & Spare Parts Availability: Choose a supplier who can deliver spare blades, motors or binding components to Arunachal Pradesh.

-

Footprint & Installation Space: Floor layout, supporting infrastructure (foundation, electricity, ventilation).

Also check whether the machine supplier provides installation, training and after-sales service — especially important in remote locations like Yingkiong.

Sourcing Notebook Making Machine for Yingkiong

Here are the steps to source and install your notebook making machinery:

-

Market Research & Supplier Selection

-

Search for Indian manufacturers or suppliers of stationery machinery.

-

Evaluate their product catalog, capacity, price, and terms of delivery to Arunachal Pradesh.

-

Ask for demo videos, specifications (motor rating, cycle times), and certifications (safety, quality).

-

-

Request Quotation & Technical Details

-

Share your production requirements (size, binding type, output per hour).

-

Obtain quotations inclusive of freight to Yingkiong, customs or transit permit (if any through neighboring states), and local taxes.

-

-

Site Survey & Layout Planning

-

Prepare your workshop layout: power hookup, floor load capacity, ventilation.

-

Ensure that the machine can be installed safely, leveling foundation or plinth as required.

-

-

Installation & Training

-

Arrange for supplier technician visit to Yingkiong for installation and start-up.

-

Train your operational staff in machine handling, quality control, and maintenance tasks.

-

-

Operational Testing & Quality Control

-

Run pilot batches to calibrate trimming, binding strength, line feed alignment, and overall finish quality.

-

Adjust settings for paper thickness, binding wire tension, and ensure minimal rejection rate.

-

-

Maintenance & Spare Parts Stocking

-

Stock essential spare parts (cutting blades, binding wire or coils, motor fuses).

-

Set routine preventive maintenance schedule to reduce downtime.

-

-

Scaling & Workflow Optimization

-

As demand grows (for schools, local markets or even regional orders), consider upgrading to higher-capacity or fully automated notebook making machine lines.

-

Monitor production KPIs: output per shift, reject rate, wastage, and power consumption.

-

Typical Applications & Business Opportunities

Operating a notebook making machine in Yingkiong can support the following applications:

-

School Exercise Books & Notebooks for local schools and tuition centres across Upper Siang district.

-

Custom Journals & Diaries for local businesses or tourist-oriented gift shops.

-

Promotional Notepads for NGOs, local government offices, or small enterprises.

-

Regional Supply to neighbouring districts in Arunachal Pradesh, or even across the border into Assam or other North-East states.

-

Export Potential (small volumes) to other regions if you maintain consistent quality and competitive pricing.

By combining good machinery with local branding and sustainable operations, you can develop a niche stationery business in this relatively underserved market.

Cost Estimates & Financial Considerations

While actual costs vary widely depending on brand, automation level, and supplier, here are some rough estimates and factors to consider:

-

Capital Expenditure (CapEx)

-

Manual or semi-automatic notebook cutter / binder units may cost anywhere from INR 50,000 up to few lakh rupees.

-

Fully automatic notebook making machine lines could cost several lakhs, depending on throughput, brand and features.

-

-

Operational Expenditure (OpEx)

-

Electricity costs in remote areas may be higher or variable; plan for backup or stable power supply.

-

Labour cost for operators, maintenance staff, raw paper procurement, binding supplies.

-

-

Return on Investment (ROI)

-

Calculate payback period by estimating revenue per notebook (cost of raw paper, binding, packaging, labour, and transport) versus selling price to schools, stationery outlets or direct customers.

-

Factor in wastage rate, downtime, maintenance and training overheads.

-

-

Funding & Loan Options

-

Explore MSME loans available through national or state-level banks.

-

Apply for scheme-based capital subsidies for industries in hilly or border areas via Arunachal Pradesh government or Central Government schemes.

-

A well-planned investment in a quality notebook making machine can deliver returns within 1 to 3 years depending on scale, productivity and market access.

Challenges & Risk Mitigation

Operating in a remote area like Yingkiong comes with its own set of challenges. Here’s how to address them:

-

Power Reliability – Remote locations may face outages or voltage fluctuations. Use stabilizers, backup generators or UPS systems.

-

Supply Chain Delays – Spare parts or binding materials may take longer to reach; maintain buffer stock.

-

Skilled Labour Availability – Provide training programmes for local workers to operate machine safely and maintain quality.

-

Quality Control – Without easy access to external quality labs, maintain in-house checks for binding strength, page alignment, trimming precision.

-

Logistics & Transport – Transporting finished notebooks to marketplaces may involve difficult terrain, long distances or limited road access; plan cost accordingly.

By proactively planning for these risks and having mitigation strategies, your notebook manufacturing setup in Yingkiong can run more reliably and profitably.

Case Scenario / Example Workflow

Imagine you install a semi-automatic notebook making machine in a 500-square-foot workshop in Yingkiong. Your target is to produce 500 exercise-books per day of size A4 with stitched binding. Using local paper sourcing and in-house binding, you supply local schools at negotiated rates.

Your steps would include:

-

Procuring paper reels or sheets via Assam-based distributor.

-

Feeding sheets into the cutter/trimmer.

-

Binding stacks using the binding machine.

-

Trimming final edges using a finishing cutter.

-

Packaging the notebooks in bundles and delivering to schools.

You monitor waste percentage, optimize setup time per batch, adjust your binding tension and trimming alignment to reduce rejects to under 5 %. At an average price of INR 50 per notebook, with daily output of 500 units, your gross revenue could reach INR 25,000 per day. After subtracting material, labour, electricity and overhead, you can estimate monthly profit margins and calculate payback period for the machinery cost.

Scaling can include making custom printed covers locally (outsourced print service or own minimal printing press) to add value and improve margins.

Maintenance Tips & Best Practices

To ensure long life and consistent performance of any notebook manufacturing equipment:

-

Daily Cleaning – Remove paper dust, lint or adhesive residue from cutters, binding heads and feeders.

-

Lubrication – Apply appropriate lubricant to moving mechanical joints at recommended intervals.

-

Alignment Checks – Regularly check alignment of cutting blades and binding path to avoid mis-cuts or binding failure.

-

Safety Checks – Ensure safety guards are intact, sensors and emergency-stop switches operational.

-

Record-Keeping – Maintain log of machine hours, maintenance performed, part replacements and any downtime events.

Also schedule periodic servicing with the supplier or trained technician to calibrate sensors, check motor health, inspect electrical wiring and replace worn components early.

Conclusion

If you are planning to establish a stationery production business in Yingkiong, Arunachal Pradesh, investing in a reliable notebook making machine is a foundational step. Consider the type of machine (automatic, semi-automatic or manual), capacity, binding options, and after-sales support. Source the equipment from trusted suppliers, ensure proper installation, train your staff, and put in place maintenance procedures.

With the right investment, you can serve local educational institutions, grow into regional markets, and build a sustainable stationery manufacturing business in this hilly region. Proper planning around cost, quality, supply chain and risk management will help you achieve success.