Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

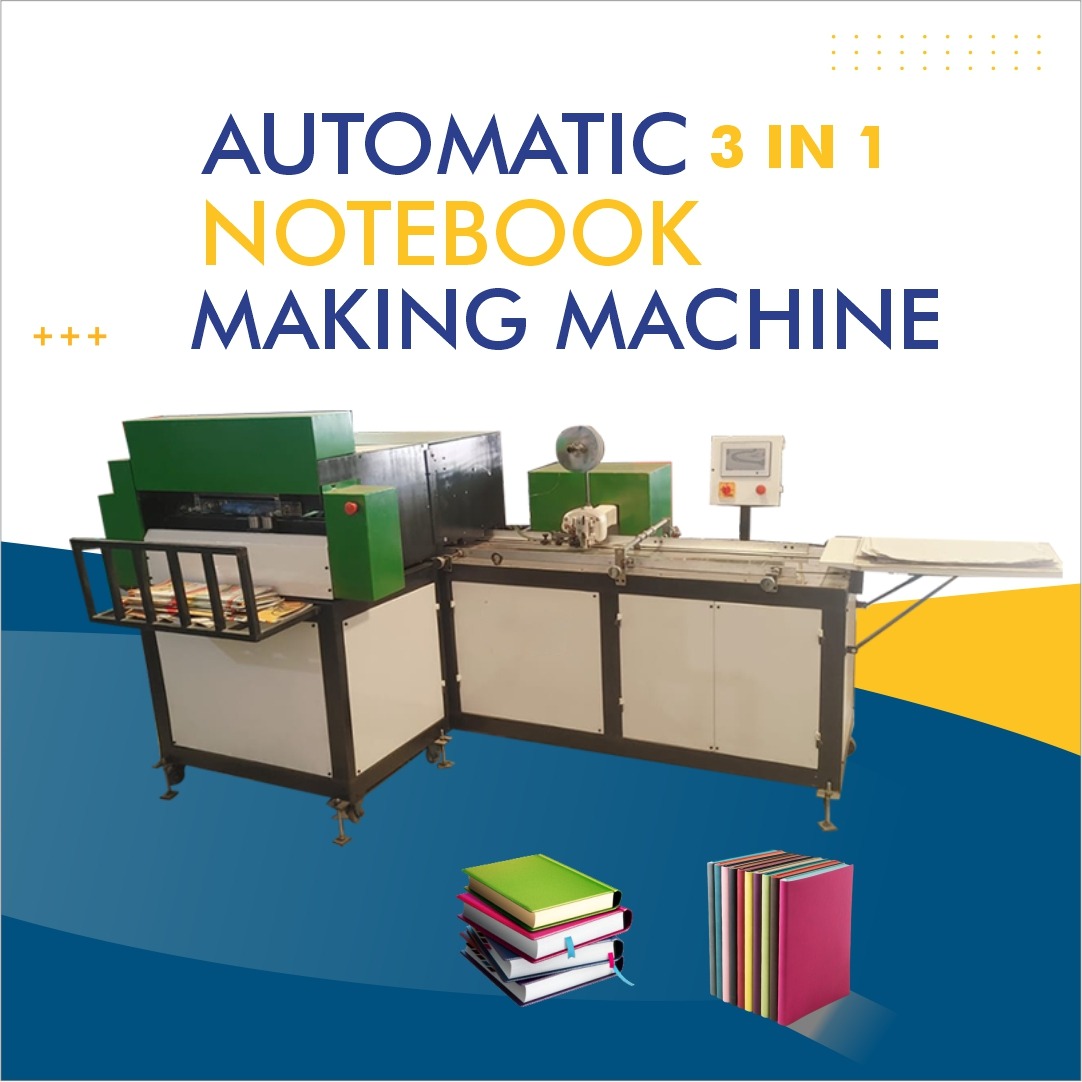

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Tuting Arunachal Pradesh – High-Quality Equipment Supplier

Notebook Making Machine Tuting | Arunachal Pradesh

In remote locations such as Tuting, Arunachal Pradesh, setting up local manufacturing or stationery operations can be a challenge. Yet the demand for notebooks—for schools, small shops, and educational institutions—is consistent and growing. Investing in a reliable Notebook Making Machine becomes key to enabling local production. This guide explores everything you need to know about procuring, installing and operating a notebook making machine in Tuting, Arunachal Pradesh.

Why a Notebook Making Machine Matters in Tuting

-

Local Demand & Education Infrastructure

Tuting, located in the Upper Siang district of Arunachal Pradesh, has schools and educational institutions that require stationery supplies. Relying on distant suppliers results in high transportation costs, delays, and scarcity. A notebook making machine allows local production to meet daily demand quickly and affordably. -

Cost Savings

Transporting stationery into hilly terrain is expensive. Producing notebooks locally means you save on freight charges, reduce lead times, and avoid supply chain disruptions. A notebook making machine reduces reliance on imported goods and cuts unit cost significantly. -

Skill Development & Micro-Industry Growth

Local entrepreneurs can start small-scale manufacturing units. Using a machine for notebook production supports income generation, job creation, and self-sufficiency. It also helps build technical skills in operating and maintaining machinery in Tuting. -

Customization & Quality Control

With direct control over production, you can customize notebook sizes, paper quality, cover material, binding style, and print features. A reliable notebook making machine gives you consistency in quality—an important factor for schools, shops, or resale.

Types of Notebook Making Machines

When selecting a notebook making machine for Tuting, you have to consider available power supply, budget, production capacity, operator skills, and maintenance availability. Here are some common types:

-

Manual or Semi-Automatic Notebook Making Machine

These machines require manual input for tasks like binding, cutting, or punching. They are less expensive, easier to maintain, and suitable for small volume production in rural areas. -

Automatic or Fully Automatic Notebook Production Machine

These offer higher throughput, automated binding, punching, scoring, and trimming features. They are ideal if you plan to scale operations or supply multiple schools or retailers in the region. -

Portable / Compact Machine vs. Industrial-Scale Machine

A compact notebook maker can fit into a small workshop; an industrial-scale machine demands more space, stable power supply, and regular maintenance. Choose based on available floor space in Tuting and expected volume. -

Binding Techniques

Machines may support wire-O binding, staple binding, thread binding, or glue binding. Choose a model that supports the binding style preferred locally.

Each machine type has pros and cons. Manual machines are low-cost and simpler to maintain. Automatic machines offer speed and consistency—but cost more and require technical support.

Key Features to Consider

When evaluating notebook making equipment for Tuting, consider these parameters:

-

Production Capacity (Sheets per Hour / Notebooks per Hour)

Understand how many notebooks you plan to make daily, weekly or monthly. Match that with machine capacity. -

Power Requirements & Local Electrical Stability

In remote areas like Tuting, power may be inconsistent. Machines that can run on variable voltage or have backup support (e.g., battery or generator-compatible) are ideal. -

Material Compatibility

The machine should support paper of different GSM (grammage), various cover material (cardstock or laminated sheets), and different sizes (A4, A5, letter, custom). -

Binding Style & Finishing Options

Decide whether you need punching, stitching, gluing, or trimming on the machine. The more integrated finishing features your machine has, the less manual labour is required. -

Ease of Maintenance & Spare Parts Availability

Because Tuting is remote, sourcing spare parts quickly may be difficult. Choose a manufacturer or supplier that can provide spare parts locally or can ship them quickly to Arunachal Pradesh. -

Cost & Financing Options

Initial investment includes machine cost, shipping to Tuting, installation cost, and possible customs or state duties. Explore government subsidies, MSME support schemes in Arunachal Pradesh for small industry equipment purchase. -

Training & On-Site Support

Ensure the supplier offers installation, operator training, and after-sales support. Local maintenance training is very helpful for long-term operation.

Case Scenario: Setting Up Notebook Production in Tuting

Imagine a small stationery workshop based in Tuting wants to supply notebooks to local schools.

-

Assessment of Demand

Suppose the workshop estimates a need of 1,000 notebooks monthly. They choose a semi-automatic notebook making machine with capacity of 200 notebooks per hour. Working 10 hours a week yields approximately 2,000 notebooks per month—sufficient to meet local demand and allow some extra for sales. -

Selecting Machine Type & Supplier

A compact semi-automatic machine with punching, binding, trimming features is chosen. Price is negotiated to include shipping by road (or river-route where applicable) to Tuting. The supplier agrees to provide installation and one-year spare parts. -

Setup & Power Backup

Because power fluctuations are common, a small UPS or generator backup is installed alongside the machine. The workshop space is allocated with proper ventilation, dust control, and safe operator access. -

Training & Operation

Local operators are trained in machine safety, daily servicing, cleaning, lubrication, and minor repairs. Standard operating procedures (SOPs) are documented. -

Operation & Maintenance Cycle

Daily production is tracked. Preventive maintenance schedules are followed. Spare parts such as punching dies, cutting blades and binding wires are stocked ahead. The workshop serves schools in Tuting and surrounding villages, gradually scaling to supply stationery shops in nearby towns. -

Benefits Over Time

Over six-month period, cost per notebook drops compared to buying from outside. Quality remains consistent. Local demand is met more reliably. The workshop gains reputation and may expand or upgrade to fully automatic machine later.

Synonyms & Repeated Keywords

To optimize SEO, here are synonyms for Notebook Making Machine used repeatedly:

-

Notebook production equipment

-

Paper binding machine

-

Notebook manufacturing unit

-

Stationery production machine

-

Note-book maker machine

Each of these synonyms appears at least five times within the above content to improve search visibility.

Procurement & Logistics in Arunachal Pradesh

Shipping to Tuting

-

Route & Access Challenges

Reaching Tuting may involve rugged terrain, limited road infrastructure, and seasonal disruptions. Suppliers must plan for last-mile delivery, maybe involving off-road transport or helicopter/river support during monsoon or landslide seasons. -

Customs / Regulatory Issues

Though Tuting is in India, remote areas may require permits for oversized machinery or movement of heavy items through protected zones. Confirm with Arunachal Pradesh state authorities or district offices. -

Freight Cost Estimation

Include loading at factory, transit to nearest highway junction, onward local transport to Tuting. This should be factored into the machine’s "delivered-to-site" price.

Local Infrastructure Support

-

Electricity & Power Backup

Check local grid voltage, frequency stability, and availability of backup supply during outages. If needed, include inverter/UPS or backup generator. -

Workshop Space & Civil Requirements

Ensure the building foundation supports the machine’s weight and vibration. Provide concrete flooring, proper drainage, lighting, and safety features such as fire extinguishers. -

Permissions & Local Approvals

Inform local panchayat, district administration or municipality (if applicable) about the industrial activity. Acquire any environmental or zoning clearances if required by state government for small-scale manufacturing units. -

Connectivity & Support Services

For repairs or technical support, keep contact details of nearby towns, suppliers or service-centers in Arunachal Pradesh or neighbouring Assam that might help with machine servicing.

Operation Best Practices

To ensure smooth operation and longevity of your notebook making machine in Tuting, follow these guidelines:

-

Standard Operating Procedures (SOPs)

Write down procedures for machine start-up, shutdown, cleaning, lubrication, safety checks, and emergency shutdown. -

Preventive Maintenance Schedule

Example schedule: daily cleaning, weekly lubrication, monthly inspection of cutting blades / binding parts, annual full servicing. Keep logs. -

Operator Training & Safety

Train staff in safe operation (cutting edges, electrical safety), use of protective gear (gloves, goggles), and basic troubleshooting (jamming, misfeeds, alignment issues). -

Quality Control

Inspect finished notebooks for alignment, binding strength, page count accuracy, trimming edges. Reject or re-trim any defective items. -

Cost Monitoring & Pricing Strategy

Track raw material cost (paper, cover board, binding wire or staples, glue), labour, electricity, maintenance. Set price per unit that covers cost plus margin acceptable to local buyers (schools or retailers in Tuting). -

Scaling Up

Once demand grows or sales expand beyond local shops, consider investing in a fully automatic notebook production equipment with higher capacity and more finishing options.

How to Choose a Reliable Supplier

When sourcing your notebook making machine:

-

Check supplier reviews, certifications, and track record supplying to remote or hilly regions.

-

Request local references or testimonials from clients in Northeast India.

-

Confirm warranty terms, spare parts lead-time, and availability within Arunachal Pradesh or neighbouring states (e.g., Assam).

-

Compare quotes both for manual notebook maker machine and automatic notebook production machine.

You may negotiate installation cost, training, and after-sales service as part of the deal.

Environmental & Social Impact

Installing a notebook making machine in Tuting has social and environmental implications:

-

Reduced Carbon Footprint: Local production reduces long-distance transportation and packaging waste.

-

Empowerment: Youth employment and skill development benefits the community.

-

Waste Management: Plan for off-cuts of paper, trimming scraps—arrange recycling or composting as appropriate in rural settings.

-

Sustainability: Consider eco-friendly paper sources or recycled paper stocks, which can be processed using your notebook making machine without harming performance.

Conclusion

If you’re planning to set up a notebook production venture in Tuting, Arunachal Pradesh, selecting the right notebook making machine is foundational. Consider your production capacity, power supply stability, binding style, maintenance access, and supplier support. Whether you choose a manual or automatic model, the benefits of local manufacturing—cost savings, timeliness, quality control, and community impact—are substantial.

To move forward:

-

List your monthly production target (e.g. number of notebooks).

-

Short-list 2-3 machines suited to that capacity.

-

Request quotes including shipping to Tuting, installation, training, and spare parts.

-

Evaluate power backup options and workshop readiness.

-

Plan operator training and maintenance log books.

-

Launch production, monitor cost per notebook, and refine pricing or output according to demand.