Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

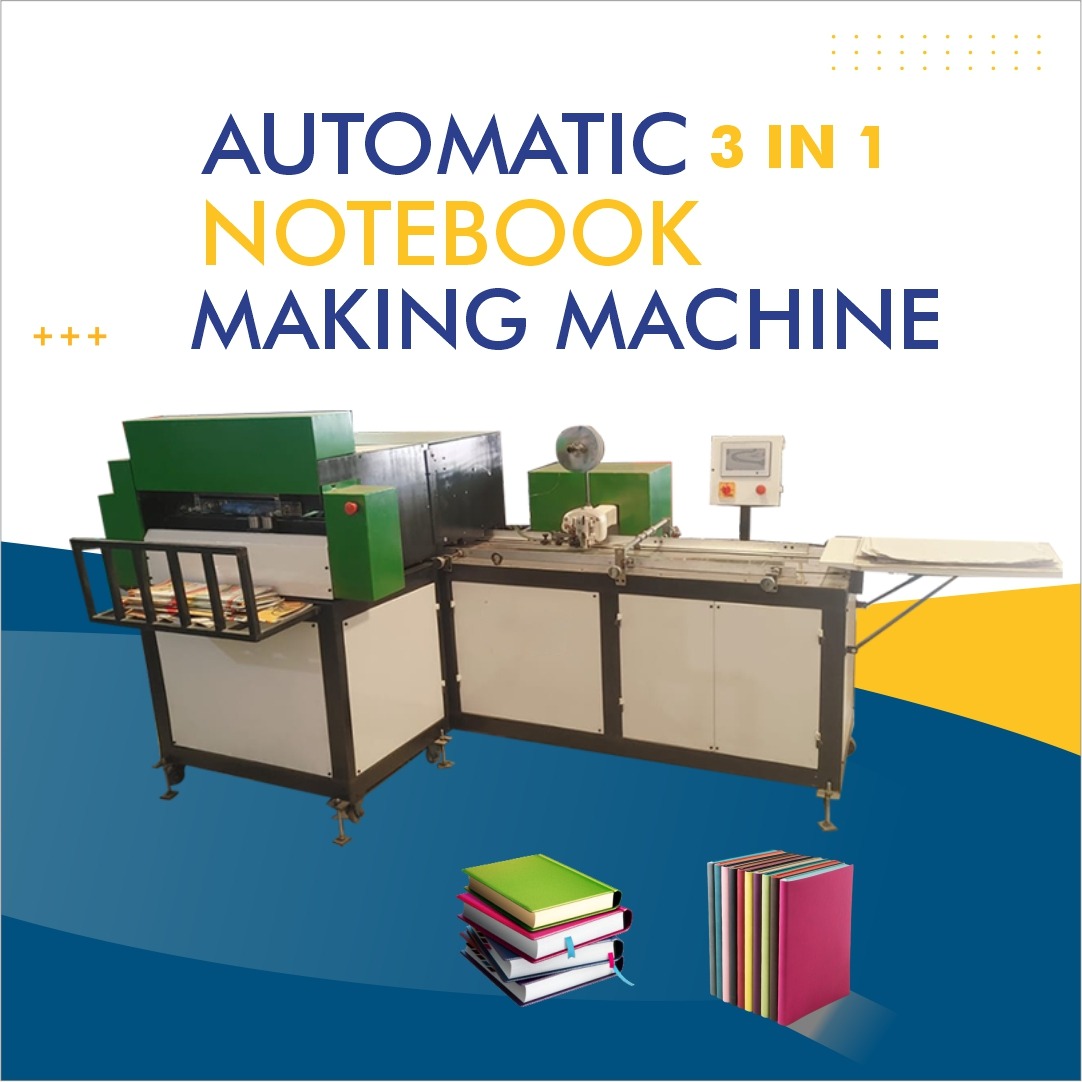

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Seppa | Best Manufacturer & Dealer Arunachal Pradesh

Notebook Making Machine in Seppa | Arunachal Pradesh

If you are searching for a notebook making machine in Seppa, East Kameng (Arunachal Pradesh), you have reached the right place. Whether you want to start a small stationery unit or scale up to full notebook production, choosing the correct machine with local support matters. This article will help you understand types of machines, cost considerations, installation & service in Seppa / Arunachal Pradesh, and how to pick the right notebook manufacturing solution for your needs.

Location Context — Seppa, Arunachal Pradesh

Seppa is the headquarters of East Kameng district in Arunachal Pradesh. DCMSME

Being in a remote hill region, any manufacturing business here must factor transport costs, availability of skilled labor, local approvals, and power infrastructure. Setting up notebook production in Seppa offers an opportunity to serve local schools, government supply orders, and regional stationery demand.

Given its status under various MSME / district-industrial profiles, Seppa is also seeing growth in small scale manufacturing units under Udyam-MSME registrations. PeakAI+1

If you locate your machine / factory near Seppa, you will need to consider access roads, electricity supply, skilled manpower, raw-material logistics, and compliance with district industrial regulations.

Types of Notebook Making Machine

When selecting a notebook making machine for Seppa or nearby areas, you should know the broad types available:

-

Manual Notebook Making Machine

-

These machines require significant manual intervention. Operators feed paper, align, fold, stitch / bind manually.

-

Lower upfront cost. Good for very small scale or pilot/educational use.

-

Production capacity may be limited (e.g. a few hundred to a few thousand notebooks per day).

-

Example: SBS NB-01 manual notebook making machine produces up to 3,000 notebooks/day. sbsmachine.com

-

-

Semi-Automatic Notebook Making Machine

-

Some processes (cutting, binding, folding) may be motorised or assisted, but require human supervision or manual steps.

-

Balanced cost & productivity. Useful when you expect modest volumes but want improved output over fully manual.

-

Example models are available via various manufacturers. asveng.com+1

-

-

Automatic Notebook Making Machine

-

Most operations automated: cutting, folding, stitching / binding, trimming etc.

-

Higher capacity, less manual labor, better consistency.

-

Higher initial investment, more power consumption, and possibly more maintenance.

-

Example: SHKI Industries offers fully automatic notebook making machine units. shkimachinery.com

-

-

Hybrid / Customized Units

-

You may choose a combined setup: semi-automatic cutting + manual binding, or automatic folding with manual finishing.

-

Useful if raw materials or power supply are variable, or you want to test market first.

-

Key Features & Specifications

When purchasing a notebook making machine in Seppa / Arunachal Pradesh, look at:

-

Production Capacity: Number of notebooks per day / per hour. This must match your demand or sales forecast.

-

Automation Grade: Manual, semi-automatic, automatic. More automation = more cost but less labor over time.

-

Machine Size / Footprint: Physical dimensions, space required. Remember your available factory space in Seppa.

-

Power Requirements: Voltage/phase, kilowatt (kW) load. Reliable electricity is essential; local infrastructure may have constraints.

-

Material & Build Quality: Steel frame, motor quality, precision of cutting / stitching mechanism.

-

Maintenance & Spare Parts Availability: Since Seppa is remote relative to big cities, you should ensure spare parts can be procured or shipped in timely manner.

-

Vendor Support / Installation: Prefer vendors who offer installation, training, and after-sales service in or near Arunachal Pradesh.

Cost Considerations

Because Seppa is remote, costs may be higher in certain ways. Keep in mind:

-

Transport & Freight: Moving heavy machinery up to Seppa may incur extra transport cost compared to metro areas.

-

Customs / Duties / Local Levies: If parts or machines come from outside Arunachal, or require regulatory clearances, budget for them.

-

Power Backup: If electricity is unreliable, you might need backup (generator / UPS), increasing installation cost.

-

Labor Costs & Skill: Labor in Seppa may be less expensive in terms of wages, but training might be required for operating machinery.

-

Raw Materials: Paper, binding wire / threads, cover sheets — local procurement may or may not be available in large volumes.

Why Set Up a Notebook Making Machine in Seppa

There are several potential advantages to locating notebook production near Seppa:

-

Closer to demand from schools, educational institutions in East Kameng and nearby districts.

-

Support from government and MSME / district industrial policies (such as Udyam registration).

-

Lower land / rental cost compared to major cities.

-

Opportunity for niche or customized notebooks (local design, local languages, customized covers for regional use).

However, you also face challenges:

-

Logistics (transporting paper & finished notebooks to markets beyond Arunachal).

-

Power & infrastructure constraints.

-

Possibly slower procurement of spare parts or machine replacement due to remoteness.

How to Procure a Notebook Making Machine for Seppa

If you plan to purchase a notebook making machine for your business in Seppa, follow these steps:

-

Define your capacity requirement: Estimate how many notebooks per day you expect (e.g. 1,000 / 5,000 / 10,000).

-

Choose Automation Level: Decide whether you want manual / semi-automatic or fully automatic.

-

Obtain Quotes: Contact several manufacturers (e.g. SBS, SHKI, ASV, etc.) for machine models, price, shipping to Arunachal Pradesh, installation cost.

-

Check for Local Permissions: Ensure compliance with East Kameng district industrial or MSME guidelines. Register under Udyam if applicable.

-

Arrange for Logistics & Setup: Plan for transport to Seppa, floor space, electrical connection, foundation / civil work if needed.

-

Staff Training: Hire or train operators to run the machine, do routine maintenance & quality control.

-

Marketing & Sales: Identify your market — local schools, stationery shops in nearby towns (Itanagar, etc.), government supply contracts, or retail sale.

Synonyms / Related Keywords (Used Above)

To help SEO, these related terms are used repeatedly in the content:

-

notebook making machine

-

notebook manufacturing machine

-

automatic notebook making machine

-

manual notebook making machine

-

semi-automatic notebook making machine

-

production equipment

-

stationery production machine

-

notebook production unit

Example Use-Case Scenario

Suppose you want to produce 2,000 student notebooks per day in Seppa.

-

You decide on a semi-automatic machine to balance cost & output.

-

You contact a vendor for a semi-automatic notebook making machine that can do 3,000–5,000 notebooks/day (for future scaling).

-

You inspect its power usage and check that your electrical load in your unit in Seppa supports it.

-

You budget for freight from supplier city to Seppa, plus installation cost.

-

After installation & training, you produce notebooks with local designs or language, supply to schools in your district, possibly expand to supply neighbouring districts.

This gives you a low-risk way to start, with capacity to scale later by upgrading to automatic or expanding machines.

Service & Maintenance Tips

To ensure long-term productivity:

-

Schedule regular preventive maintenance (lubrication of moving parts, checking cutting blades, aligning binding mechanism).

-

Keep spare consumable parts in stock (binding wire or thread, glue, cutting knives, motor spare fuses).

-

Record machine usage hours and plan for replacement parts in advance.

-

Maintain quality control: check that each notebook’s pages are aligned, cover is properly affixed, binding is secure.

-

Monitor energy consumption and switch off / shut down the machine at idle times to reduce electricity cost.

Conclusion

Choosing the right notebook making machine in Seppa, Arunachal Pradesh demands balancing cost, capacity, availability of service & infrastructure. Whether you start with a manual model or invest in semi-automatic / fully automatic equipment, proper planning of logistics, permissions, installation, and ongoing maintenance will make the venture viable. With growth in demand for stationery in the region and support from local business / MSME infrastructure, a well-chosen machine can offer you an opportunity for sustainable local manufacturing.