Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

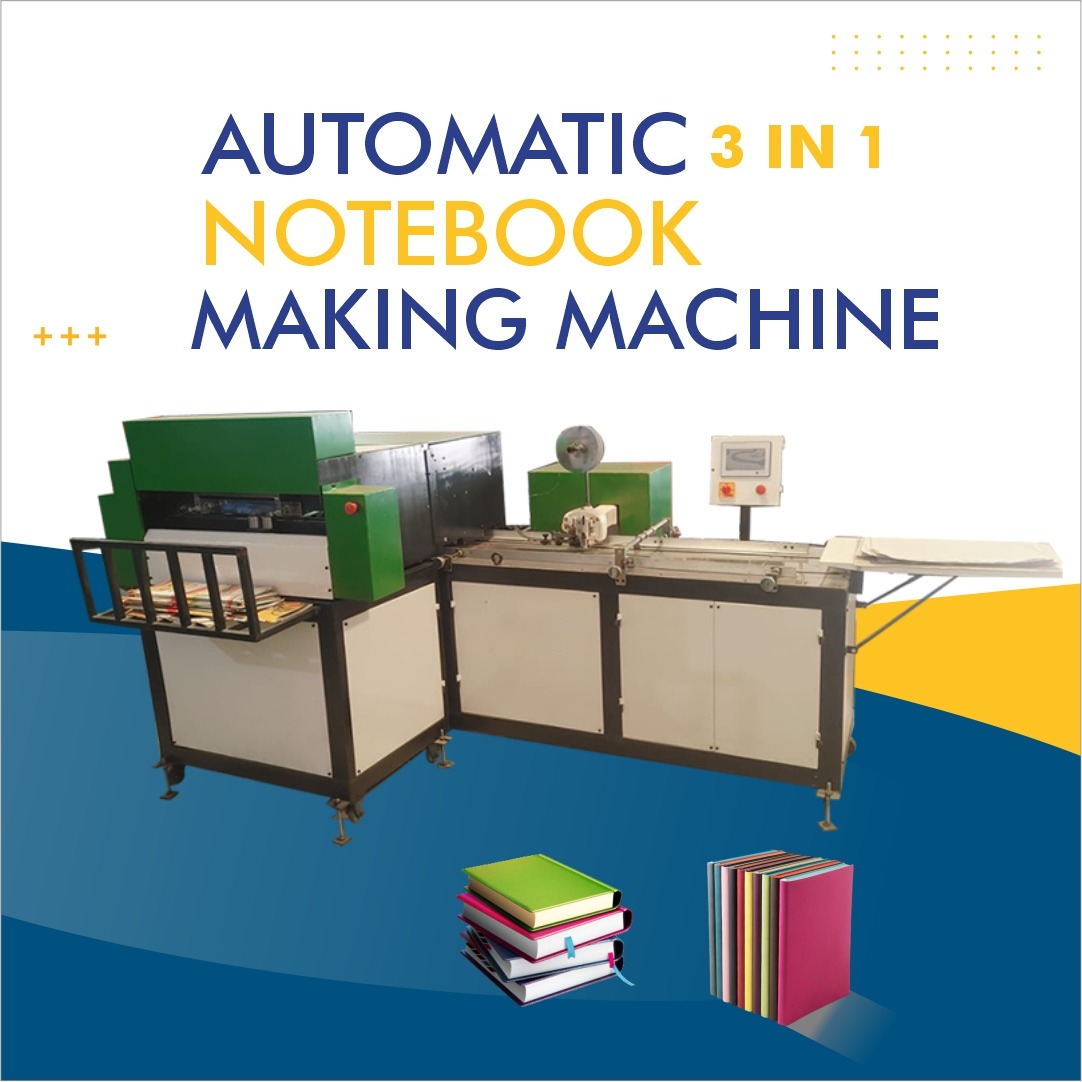

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier Sagalee – Best Notebook Machine in Arunachal Pradesh

Notebook Making Machine Sagalee | Arunachal Pradesh

Sagalee is a town in Papum Pare district of Arunachal Pradesh. Wikipedia If you are looking to establish or upgrade a notebook manufacturing facility in this region, investing in a quality notebook making machine can be the key to success. This article explores everything you need to know about acquiring, installing, operating and benefiting from a notebook manufacturing machine in Sagalee, Arunachal Pradesh.

In this guide you will find:

-

Why Sagalee is a suitable location for notebook manufacturing,

-

Types of notebook making machines available,

-

Specifications & features to look for,

-

Installation & training considerations,

-

Cost & return on investment,

-

Local challenges & opportunities,

-

Steps to procure and maintain your machine.

We also repeat key target terms such as notebook making machine, notebook manufacturing machine, automatic notebook machine, etc., to boost SEO relevance.

2. Why Choose Sagalee, Arunachal Pradesh

-

Sagalee is part of Papum Pare district in Arunachal Pradesh. It falls under a semi-rural, growing economy with increasing demand for stationery supplies in schools, colleges, offices, and governmental institutions. Wikipedia+1

-

Being closer to educational centres and regional markets, setting up a notebook production unit in Sagalee helps reduce transportation cost of finished notebooks across Arunachal Pradesh.

-

The Indian government supports MSME / small scale industries in remote and North-East regions, which may offer incentives for establishing manufacturing units in places like Sagalee.

-

Proximity to raw material suppliers (paper wholesalers), potential workforce, and relatively lower labour costs makes Sagalee a viable location for notebook manufacturing.

Together, these factors make Sagalee an attractive place to deploy a notebook making machine and build a stationery manufacturing business.

3. Types of Notebook Making Machine

When selecting a notebook making machine for your facility in Sagalee, you will typically choose among the following types:

| Type | Description |

|---|---|

| Manual Machine | Requires operator input at each stage (folding, stitching / binding, cutting). Lowest cost. |

| Semi-Automatic Machine | Automates some processes such as cutting / trimming / binding. Operator needed for loading / feeding. |

| Fully Automatic / Automatic Machine | Minimal manual intervention. Machine handles multiple steps—folding, ruling/perforation, stitching or glue binding, trimming, pressing with speed control. |

Features To Consider:

-

Production capacity (notebooks per hour)

-

Size compatibility (A4, A5, custom sizes)

-

Binding method (stitching / stapling / glue / thread)

-

Cutting / trimming precision

-

Ruling / perforation / margins

-

Power requirement (electric phase, voltage)

-

Automation grade & control panel

-

Material compatibility (paper GSM, cover board thickness)

For example, Laghu Udyog offers semi-automatic notebook making machines capable of various speeds and caters to Northeast Indian states. laghuudyogbharat.com+1 They have models that support capacities from lower volume to higher throughput.

4. Specifications & Features

To operate efficiently in Sagalee, you would want a machine with specifications tailored to local requirements:

-

Production Speed: For a startup or small-scale unit, semi-automatic machines delivering 1,000-5,000 notebooks/hour may suffice. For higher volumes consider machines rated higher.

-

Supported Sizes: A4, A5, custom sizes as demanded by schools or offices in Arunachal Pradesh.

-

Binding Type: Most notebooks use stitch binding or thread binding. The machine should support ruling & stitching / binding features integrated.

-

Power & Automation: Given fluctuations in remote power supply, select machines with stable power ratings, and possibly offline buffering or UPS support.

-

Durability & Local Service: Prefer brands / suppliers who provide service in Northeast India. Machine frame, spare parts availability, and training are critical.

-

Ease of Operation: Local workforce may require training; user-friendly interface and maintenance access is essential.

Also consider safety features and compliance with Indian machine safety norms.

5. Installation, Training & After-Sales Support

One of the most important considerations for notebook making machine is installation & commissioning. If you install a machine in Sagalee, you will need:

-

Local technician or support from the supplier

-

Operator training (folding, binding adjustment, cutting calibration)

-

Spare parts availability (blades, staples / thread / glue, electronic components)

-

Periodic maintenance schedule

Choose a supplier that either offers on-site training or remote guidance. Given the remoteness of Arunachal Pradesh, suppliers who can deliver and service machinery to your location or nearest accessible city are preferable.

6. Cost, Pricing & Return on Investment

When you select a notebook making machine, you must analyze the capital cost vs expected output & revenue:

-

Capital cost includes the machine price, shipping to Sagalee, customs or freight (if coming from outside state), installation charges, and initial raw material cost.

-

Running cost includes electricity consumption, labour for operators, maintenance, consumables (e.g. binding supplies, staples/thread/glue, cutting blades).

-

Revenue side depends on how many notebooks you can produce per day, your selling price per notebook, and demand in the local market and nearby districts.

Example scenario:

If your machine can produce 2,000 notebooks / hour, working 8 hours/day, that’s 16,000 notebooks/day. If you price each notebook at ₹20 (or based on local market), revenue potential is considerable once you sell to schools / stationery shops.

You must deduct operational costs, packaging, distribution cost from your revenue to find payback period. Typically many units recover their investment within 1–3 years depending on scale and demand.

Consider also seasonal demand peaks (e.g. ahead of academic session) – ensuring you produce enough inventory during peak.

7. Local Challenges & Opportunities

Challenges:

-

Logistic constraints: transporting heavy machinery to Sagalee may incur additional freight cost, road condition constraints.

-

Power supply reliability: occasional outages or voltage fluctuations may require electrical backup or stabilizer.

-

Raw material sourcing: paper of required quality, binding supplies may be sourced from outside Arunachal Pradesh which adds transport time and cost.

-

Skill gap: finding trained machine operators in remote locations may be difficult initially.

Opportunities:

-

Government incentives for Small Scale Industry (SSI) or MSME units in North East India. Potential subsidies, concessional electricity rates, or tax exemptions.

-

Local demand from schools (public & private), colleges, government offices for custom notebooks, homework books, registers, diaries, student exercise books.

-

Customization opportunities: local art, motifs, regional patterns on notebook covers – you could offer personalized or regional-themed stationery.

-

Expansion into nearby districts / neighbouring states given your production base in Sagalee.

8. Steps to Procure & Operate a Notebook Making Machine in Sagalee

Here is a suggested step-by-step plan:

-

Market Survey & Demand Assessment

Estimate local demand from schools, stationery shops, government tenders in Papum Pare & nearby districts. -

Choose Machine Type

Decide capacity required, automation grade (manual / semi-automatic / automatic), binding method. -

Identify Supplier

Contact manufacturers such as Laghu Udyog (which serve Northeast India) or other vendors who can ship & support equipment to Sagalee. laghuudyogbharat.com+1 -

Request Quotation

Include price, shipping cost, customs / inter-state freight, installation, training cost and warranty terms. -

Secure Funding / Government Incentive

Apply for MSME or SSI registration; explore schemes by Arunachal Pradesh government for small-scale manufacturing units. -

Venue & Infrastructure Preparation

Prepare your facility in Sagalee: flooring, electricity connection, ventilation, safety protocols, workspace for material handling. -

Installation & Training

Coordinate with supplier to install machine on-site, perform trial runs, calibrate settings. Train your staff. -

Procurement of Raw Material & Consumables

Source quality paper, binding supplies; ensure steady supply chain. -

Production & Quality Control

Start production, monitor quality (ruling alignment, binding strength, finishing), ensure packaging standards. -

Marketing & Sales

Approach local stationery shops, schools, tender contracts; possibly brand your notebook products; deliver to neighbouring markets. -

Maintenance & Scaling

Maintain preventive maintenance schedule, plan for spare part replacement. Once demand grows, scale up by adding another machine or upgrading capacity.

9. Conclusion

Launching a notebook manufacturing business in Sagalee, Arunachal Pradesh with the right notebook making machine can be a high-potential venture. With careful planning, assessment of demand, smart selection of machine features (automatic or semi-automatic depending on your scale), and robust execution including installation, training, and maintenance, you can build a successful stationery production enterprise.