Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

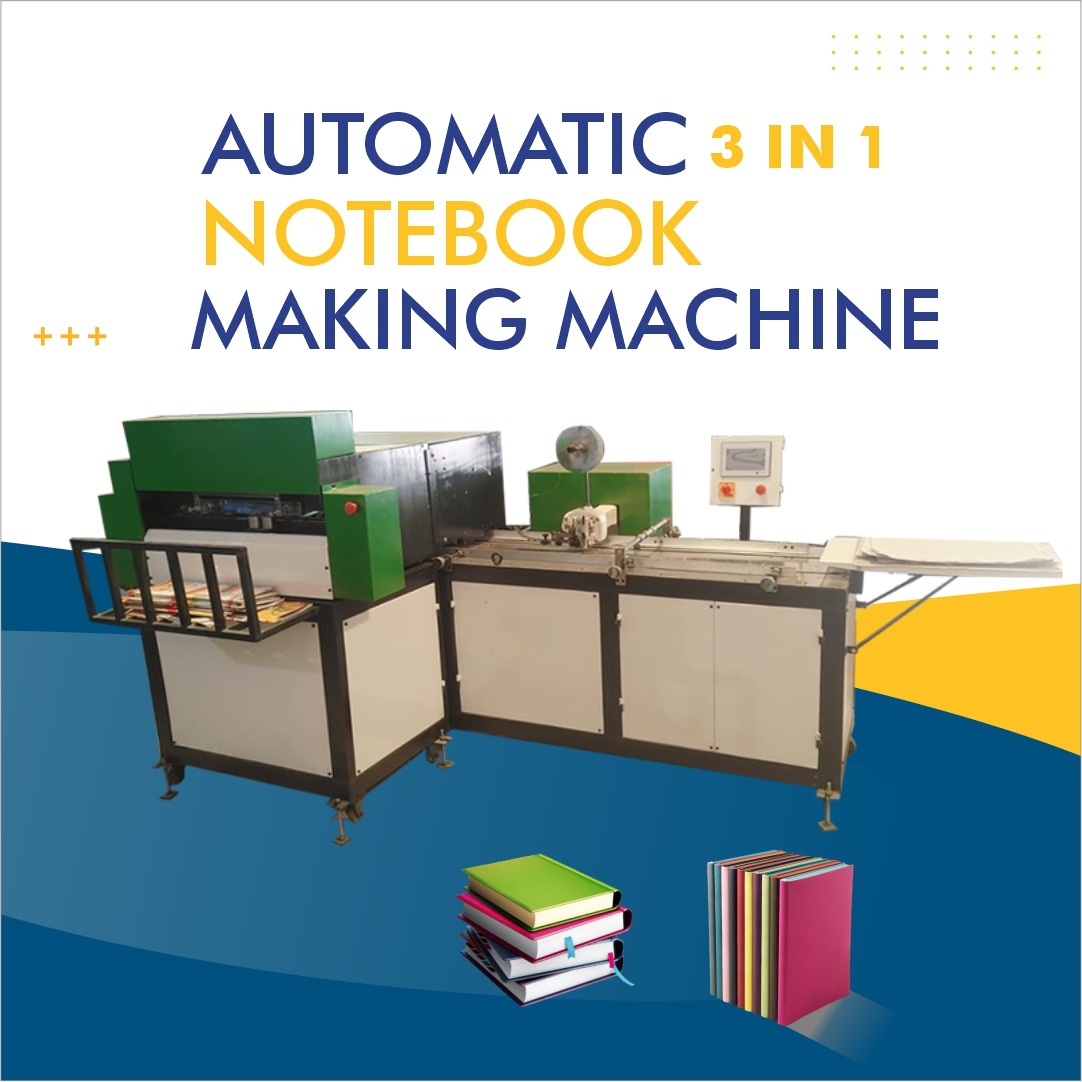

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Roing Arunachal Pradesh | Best Machinery Supplier

Introduction

Arunachal Pradesh is witnessing rapid growth in small-scale industry and cottage manufacturing units. One area with bright potential is stationery production, particularly notebooks. If you are looking to establish or upgrade a production unit in Roing, having a notebook making machine is essential. In this article, you will find comprehensive information on purchasing, installing, and using a quality notebook production equipment in Roing, Arunachal Pradesh. We cover features, types, suppliers, business prospects, and technical guidance to help you make a well-informed decision.

Why Choose Notebook Making Machine in Roing, Arunachal Pradesh

-

Strategic Location

Roing is well-positioned for small-scale industrial growth with access to road networks, local labour, and proximity to raw materials. Setting up a notebook production plant here could tap both local schools and regional markets. -

Untapped Market Opportunity

Many schools, shops, and stationery outlets in Arunachal Pradesh currently source notebooks from outside the state. By establishing local notebook production you can reduce logistics costs and supply faster to district towns like Pasighat, Tezu, Namsai, and beyond. -

State Incentives & Support

The Government of Arunachal Pradesh offers support for micro, small and medium enterprises (MSMEs). Investment in manufacturing machinery like stationery manufacturing machine may qualify for subsidies or incentives. Check with Arunachal Pradesh Industrial Development & Financial Corporation (APIDFC) or relevant state departments. -

Quality and Customisation

A modern notebook making machine or automatic notebook maker enables you to customise cover designs, page counts, binding types, and sizes. That gives you a competitive edge over generic, mass-imported notebooks.

Types of Notebook Making Machines

Depending on your production capacity and budget, you can choose among various types of machines:

| Type | Description |

|---|---|

| Manual / Semi-automatic Notebook Production Equipment | These require manual feeding or some human intervention. Ideal for low to medium volumes or pilot setup. |

| Fully Automatic Notebook Maker | These handle automatic feeding of sheets, cutting, binding, binding cover folding, and trimming. Suitable for higher throughput. |

| Booklet Binding Machine | Focuses on binding notebooks or booklets after sheets are cut and printed. It may work alongside cutting or trimming machines. |

| Cover Laminating + Binding Line | Includes machines for laminating covers, trimming covers, crease folding, and binding with staples or stitching. |

Each variant of notebook production equipment has its own cost, maintenance needs, and skill requirements.

Essential Features to Look for

When selecting a notebook making machine, pay attention to these features:

-

Production Capacity: pages per minute, number of notebooks per hour.

-

Maximum Size & Page Count: what formats can the machine handle (e.g. A5, A4, custom sizes).

-

Binding Type: stapled binding, sewn binding, spiral binding (if applicable).

-

Automation Level: manual interventions vs automatic paper feeding, trimming, and binding.

-

Accuracy & Finish Quality: margins, trimming quality, alignment of pages and cover.

-

Power Requirements: voltage, phase, consumption—important in Roing where electricity supply infrastructure might have constraints.

-

After-sales Support & Spare Parts: consider supplier proximity, availability of spare parts, maintenance service.

-

Cost & Return on Investment: initial capital cost, operating cost, manpower cost, and expected payback period based on sales.

Using the right stationery manufacturing machine with the correct technical specification can significantly reduce wastage and improve finished notebook quality.

Synonyms & Related Terms Usage

Throughout this content we will use the following synonyms for the main phrase:

-

Notebook making machine

-

Notebook production equipment

-

Stationery manufacturing machine

-

Booklet binding machine

-

Automatic notebook maker

You will see these used repeatedly to emphasise relevance to search queries.

Supplier Selection & Import Considerations

If you are looking to buy a notebook production equipment for your Roing-based factory, consider the following steps:

-

Local or National Suppliers

Check suppliers across India who have experience supplying notebook manufacturing machines. Request references where they have installed similar equipment in northeast India. -

Technical Demonstration

Ask for a demo video or factory visit to see a stationery manufacturing machine in operation. Check the quality of binding, speed, and reliability. -

Transportation & Installation

Because Roing is in Arunachal Pradesh and may involve road logistics through hilly terrain, ensure the supplier can arrange delivery and installation at your premises. -

Customisation & Upgrades

Ensure your automatic notebook maker can be upgraded later—for example adding a cover laminator, or increasing page count capacity. -

Training & Support

Insist on training for your staff—machine operations, safety protocols, maintenance. Confirm that spare parts for your notebook making machine are available locally, or can be dispatched quickly. -

Compliance & Certification

The machine should meet electrical safety standards, and any industrial licensing or environmental approvals applicable in Arunachal Pradesh.

Business Case & Production Planning

Investment Estimate

Below is a rough template you might use for planning a small notebook production facility in Roing:

| Item | Estimate |

|---|---|

| Cost of notebook manufacturing machine | ₹ X lakhs (depending on automation level) |

| Power Setup / Electrical Works | ₹ Y lakhs |

| Building or Factory Space | Rent or Construction Cost for facility (office + production floor) |

| Raw Material Cost | Paper, cover boards, laminating film, staples or binding wire |

| Labour Cost | Operators, assistants, supervisory staff |

| Annual Maintenance & Downtime Buffer | ~5 % of capital cost per annum |

| Marketing & Packaging | Branding, printing customised covers, packaging boxes |

| Sales Price & Volume Estimate | For example, selling 10,000 notebooks per month at ₹ Z per piece yields turnover of ₹ (10,000 × Z). |

Break-Even & Profitability

Use the estimates to calculate how many notebooks per month you must sell to cover fixed costs and recoup your capital expense. Factor in demand from schools, colleges, stationery markets, and institutional supply in Arunachal Pradesh.

Product Range & Diversification

With a good notebook making machine or booklet binding machine, you may diversify into related stationery products such as:

-

Notepads and memo pads

-

Diaries, planners, and exercise books

-

Promotional gift-pack notebooks with custom covers

Such diversification helps absorb fixed costs and improves profitability.

Site & Installation in Roing

Location & Infrastructure

Select a site near Roing town with adequate infrastructure: reliable electricity, drainage, road access, and security. Ensure that the production area is properly ventilated and has enough floor space for raw paper storage, machine operation, finished goods stacking, and packaging.

Utility Requirements

Determine the voltage, amperage, and phase (single or three-phase) needed by your stationery manufacturing machine. Verify that local power supply meets the specifications. If not, consider installing dedicated transformer or power stabiliser.

Workflow Design

Design a productive workflow: raw-paper storage → cutting/trimming → binding (booklet binding machine or automatic notebook maker) → cover finishing → packaging → dispatch. Use lean layout planning to minimise material movement and wastage.

Workforce Training

Train staff in operating the notebook making machine safely and efficiently. Establish standard operating procedures (SOPs), safety protocols, cleaning schedules, and routine maintenance logs.

Quality Control

Set up QC checks after binding: check alignment of pages and cover, ensure binding integrity, inspect trimming margins, check packaging weight and presentation. Such consistent quality will help you build good reputation with institutional buyers.

Marketing & Sales Strategy

To sell notebooks produced via your notebook making machine in and around Roing:

-

Local School Tie-ups

Approach government and private schools in Roing and nearby districts (like Anjaw, Lower Dibang Valley) for annual supply contracts. -

Retail Partnerships

Partner with stationery shops in Pasighat, Dibrugarh (Assam border), and Tezu for distribution. Emphasize advantages of “Made in Arunachal” notebooks in promotional material. -

Government Tender Participation

Government departments sometimes invite tenders for supply of exercise books / registers. Register your MSME and bid for those tenders. Having your own notebook production equipment gives you credibility. -

Online & Social Media Branding

Create a brand name for your notebooks. Use local themes or cultural motifs (Tribal art of Arunachal) on covers. Promote via local-language flyers, social media groups, and marketplaces. -

Custom Orders & Bulk Supply

Offer customised notebook printing and binding for offices, NGOs, tourist lodges, or gift-shops. Use your automatic notebook maker’s features to support bespoke orders (custom cover design, size, page count).

Maintenance & Sustainability

-

Schedule regular preventive maintenance of all moving parts, blades, motors in your machine.

-

Stock essential spare parts (cutting blades, belts, binding wires).

-

Monitor electricity consumption and machine uptime to optimise productivity.

-

Ensure safe disposal of trimming waste (paper off-cuts) and adopt recycling where possible.

-

Plan for future expansion: if demand grows, you should be able to add a second notebook production equipment or expand shifts.

Risk Factors & Mitigation

While investing in an automatic notebook maker or stationery manufacturing machine has clear advantages, you should consider:

-

Supply Chain Delays – import of machine parts or raw materials may be delayed due to terrain or customs. Mitigate by maintaining buffer stocks.

-

Power Interruptions – in mountainous regions, electricity cuts or voltage fluctuations can damage motors. Use stabilisers or UPS backups.

-

Demand Fluctuations – school purchases vary with academic calendar. Plan seasonal buffer inventory and diversify end-users.

-

Skill Shortage – training local staff to operate high-end notebook production equipment takes time. Partner with technical institutes or employ experienced technicians.

Case Study (Hypothetical Example)

Suppose you install a semi-automatic notebook making machine in Roing with capacity of 500 notebooks per day. The initial cost is ₹5 lakhs for the machine and ₹2 lakhs for infrastructure upgrades. You plan to sell each notebook at ₹50. Monthly fixed costs (rent, power, labour) are ₹1 lakh. Variable cost per notebook is ₹20 (paper, cover film, staples).

-

Monthly production: 500 × 25 working days = 12,500 notebooks

-

Revenue: 12,500 × ₹50 = ₹6,25,000

-

Variable cost: 12,500 × ₹20 = ₹2,50,000

-

Gross profit: ₹3,75,000

-

Subtract fixed cost: ₹1,00,000 → Net operating margin ~ ₹2,75,000 per month

-

Payback period: ₹7 lakhs capital cost / ₹2,75,000 ≈ 2.5 months

This simplified model shows that with efficient use of the notebook machine and good market demand, the venture can be profitable in Roing.

Conclusion

Investing in a notebook making machine or related notebook production equipment in Roing, Arunachal Pradesh can unlock strong business potential. By selecting the right level of automation, securing reliable supply chains, planning your operations carefully, and marketing effectively, you can establish a stationery manufacturing venture that serves schools, retailers, and institutional buyers across the region.