Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

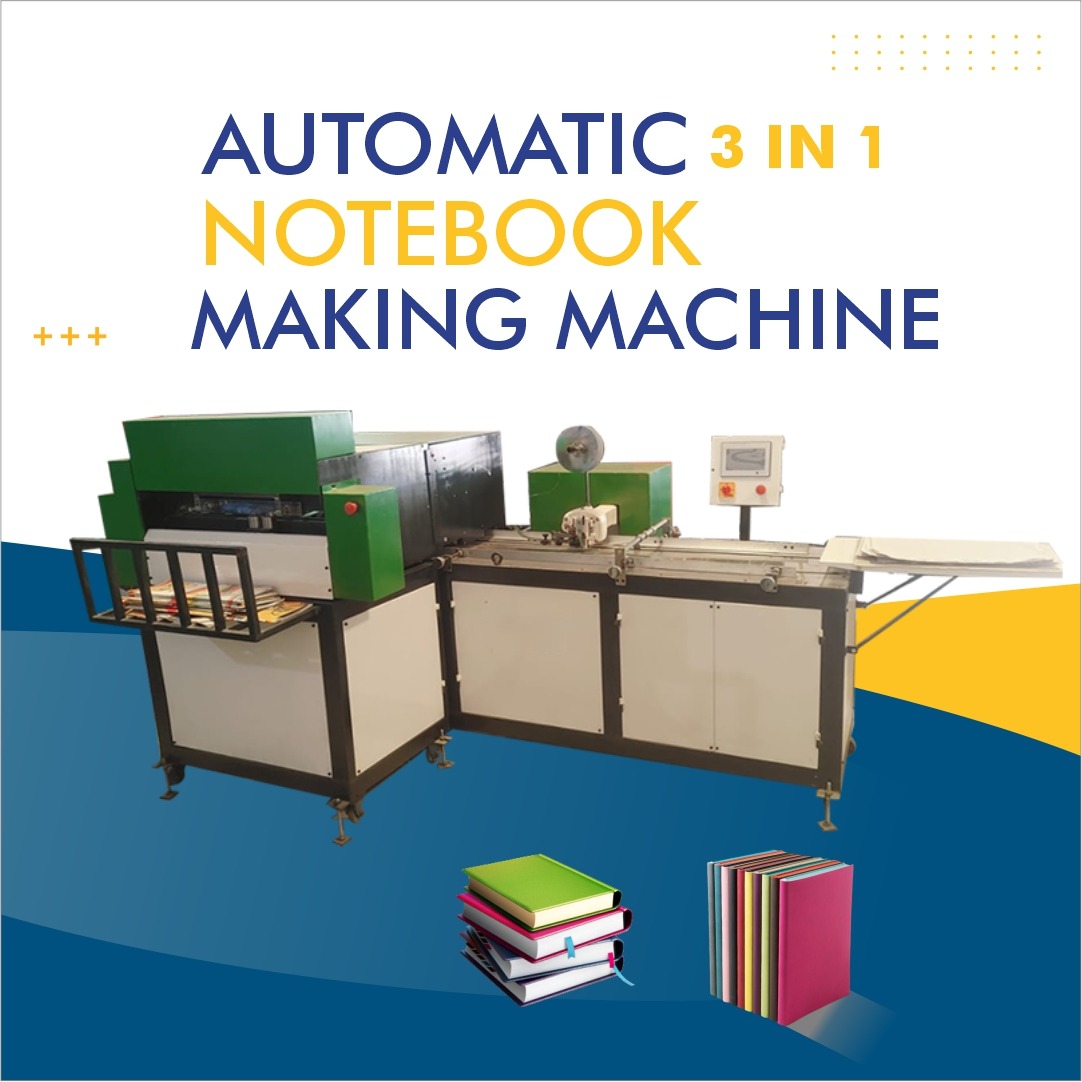

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Mago Arunachal Pradesh | Buy, Service & Setup

Notebook Making Machine in Mago | Arunachal Pradesh

Arunachal Pradesh is seeing increasing interest in small-scale manufacturing and cottage industries under various state and central schemes. Entrepreneur India+1 For entrepreneurs in Mago, Arunachal Pradesh, setting up a notebook manufacturing unit can be a viable opportunity. A core requirement for this is the notebook making machine. Whether you are planning manual, semi-automatic, or fully automatic operations, this guide will cover everything you need to know – from types of machines, cost, installation challenges, to local permits and benefits.

This page explains the benefits of setting up notebook making operations, what machine types are available, how you can source them, cost factors, site preparation, technical details, and operational tips. It also highlights how this applies in the local context of Mago, Arunachal Pradesh.

Why Consider a Notebook Making Machine in Mago, Arunachal Pradesh

Local Industry Policy & Support

-

Arunachal Pradesh has several schemes and infrastructure to support small industries, village‐level manufacturing, and MSMEs. NEDFi+2Kuey+2

-

District Industrial Centers and relevant departments are likely to provide guidance, subsidies, or permits for new manufacturing units. Entrepreneur India+1

-

There is growing impetus to promote rural entrepreneurship and reduce dependency on imports by local manufacturing units.

Market Opportunity

-

Demand for school stationery, registers, notebooks remains steady in Northeast India.

-

Local schools, colleges, and small shops around Mago and nearby towns may prefer lower-cost local production over imported notebooks.

-

You can target neighbouring districts within Arunachal Pradesh and even Assam for supply.

Strategic Location Considerations

-

While Mago is remote compared to metropolitan hubs, establishing production locally reduces transportation costs of finished goods.

-

You should verify access to reliable electricity, road connectivity, workforce availability, and local raw materials (paper, boards, binding supplies).

Types of Notebook Making Machines

When considering procurement, there are several categories of notebook making equipment (synonym): manual, semi-automatic, and fully automatic. Here’s a rundown:

Manual Notebook Making Machine

-

These are labor-intensive machines that require manual feeding, cutting, stitching or binding.

-

Example: “Manual Notebook Making Machine Full Setup (SBS NB-01)” has capacity around 3,000 units/day. sbsmachine.com

-

Advantage: lower capital cost, simpler operation, easier to maintain locally.

-

Suitable for small batch production, startups or pilot manufacturing in Mago.

Semi-Automatic Notebook Making Equipment

-

Combines manual intervention with mechanized parts such as cutting, folding, binding.

-

Example: ASV Engineering’s semi-automatic notebook making machine (“36” model) is marketed for daily capacity in thousands of units. asveng.com

-

Offers better throughput than manual while being less costly than fully automatic.

-

Useful when scaling from prototype to regular production.

Automatic Notebook Making Machine

-

Fully automatic machines handle sequential operations (cutting, folding, stitching, trimming) without manual intervention.

-

For instance, TradeIndia lists machines capable of producing 9,000 – 10,000 pcs/day. TradeIndia

-

These are higher cost, require better maintenance but offer economies of scale if production volumes are high.

Other Related Equipment

-

Notebook cutting machine

-

Register making machine (synonym)

-

Register binding or book binding machine for customized variants

-

Edge squaring, trimming machines

-

Paper folding / creasing units

-

These supplementary machines are part of a full notebook production line.

Features & Technical Specifications

When evaluating a notebook production machine (synonym), consider the following:

| Feature | Typical Parameters |

|---|---|

| Production Capacity | e.g. 3,000 / day, 5,000 / day, up to 9,000–10,000 units/day TradeIndia+1 |

| Automation Grade | Manual / Semi-automatic / Automatic |

| Motor / Power Requirement | Single phase or 3-phase electric supply; KW rating depends on model |

| Size of Paper & Cutting Format | A5, A4, custom sizes; size of cutting blades |

| Binding / Stitching Type | Staple / Thread / Glue / Spiral (depending on machine) |

| Material of Construction | Mild steel, case-hardened components, bearing type parts |

| Footprint & Installation Space | Floor area and ceiling height; structural base support |

| Maintenance Requirements | Access to spare parts, local technicians, periodic lubrication / calibration |

| Quality of Output | Page alignment, stitched binding quality, trimming accuracy |

Also consider whether machine suppliers provide after-sales service and spare parts in Northeast India.

Cost & Investment Estimate

Here’s a rough outline of cost components:

-

Machine Cost

-

Manual machines could cost in lower lakhs of rupees.

-

Semi-automatic machines may range higher depending on features (cutting size, binding capacity).

-

Fully automatic machines are more expensive (several lakhs to over ten lakhs rupees). Examples from JustDial / TradeIndia show prices in that range. Justdial+1

-

-

Site Preparation & Civil Work

-

Construction or allocation of a small workshop space in Mago.

-

Flooring, electrical wiring, safety fittings.

-

-

Power & Utilities

-

Ensure stable electricity supply (single-phase or three-phase as required).

-

Backup power (generator / inverter) if grid fluctuations are a concern.

-

-

Labour & Training

-

Hire or train local workers to operate the notebook making machine.

-

Training for maintenance, quality checking, raw material handling.

-

-

Raw Material & Input

-

Paper sheets, boards, binding supplies (e.g. thread, staples, glue), cover material.

-

Transportation cost of raw material into Mago area.

-

-

Regulatory & Licensing

-

Permits from the Industrial Department / District Industry Center.

-

Compliance with local taxes, labour laws, environmental norms.

-

-

Logistics & Shipping

-

Cost to ship the machine to Mago (which may be remote / hilly terrain).

-

Freight / customs / handling charges from supplier location to Arunachal Pradesh.

-

-

Working Capital & Financing

-

Upfront capital may be financed through MSME schemes or state subsidies.

-

Routine working capital for raw material procurement, utilities, salaries.

-

A realistic budget for small-to-medium scale setup might start from a few lakhs rupees (for manual / semi-automatic) and scale up to several lakhs or even over ₹10 lakh if opting for a fully automatic line.

Setting Up in Mago: Practical Steps

Here is a recommended checklist tailored for Mago, Arunachal Pradesh:

-

Market Survey & Demand Assessment

-

Talk to local schools, stationery shops, educational institutions in nearby villages.

-

Estimate potential monthly demand / quantities.

-

-

Acquire Permissions & Identify Support Schemes

-

Visit the Arunachal Pradesh Department of Industries website. indarun.gov.in

-

Check for MSME / startup support schemes.

-

Explore whether Mago is under any industrial cluster or zone.

-

-

Select Machine Vendor

-

Seek quotations for manual / semi-automatic machines from suppliers (e.g. Delhi / Kolkata / other manufacturers).

-

Compare specs: capacity per day, power consumption, maintenance terms.

-

-

Arrange Transportation & Installation

-

Finalize delivery logistics to Mago (road condition, permits for transporting heavy equipment).

-

Prepare workshop location: bench, layout, safety.

-

-

Hire & Train Workforce

-

Engage locals with mechanical aptitude.

-

Ensure personnel understand operating procedures, safety standards, quality inspection.

-

-

Quality & Testing

-

Produce initial test runs of notebooks.

-

Check binding strength, dimensions, finish.

-

Iteratively improve process (e.g. trimming accuracy, alignment).

-

-

Marketing & Distribution

-

Brand the notebooks as “Made in Mago, Arunachal Pradesh”.

-

Approach local shops, government schools, district stationery counters.

-

Expand into nearby towns / districts; possibly tie-up with supply-chain networks.

-

-

Scale-up Planning

-

Start with manual or semi-automatic capacity.

-

Track monthly output, waste / rejects, defect rate.

-

Once demand increases, plan upgrade to higher capacity semi-automatic or automatic notebook making machine.

-

Challenges & Risk Mitigation

While the opportunity is promising, you should consider:

-

Logistics Delay: Moving heavy machinery into remote areas may face delays due to road infrastructure or weather.

-

Power Reliability: Fluctuating power could damage sensitive components; consider stabilizers or UPS.

-

Skilled Maintenance: Spare parts or technical support may not be locally available; ensure supplier provides remote or periodic service visits.

-

Demand Fluctuations: School seasonality or changing stationery preferences may affect sales volumes; diversify products (registers, custom notebooks).

-

Competition: Imported or large-scale notebooks from outside the state may compete on price; your edge would be local delivery time & customization.

Benefits & Revenue Potential

Here’s a summary of advantages:

-

Local production reduces shipping cost & time.

-

Customised designs (regional artwork, local tribal motifs on covers) can differentiate your notebook product.

-

Value-add: you can also produce registers, exercise books, diaries etc. using the same notebook making equipment (book binding machine / register making machine as synonyms).

-

Over time, upgrading to higher capacity machines increases economies of scale and profit margin.

Revenue projection depends on production volume, pricing per notebook, cost per piece (raw material + labour + utilities). If you can produce 2,000 notebooks per day at ₹20 per notebook (sale price), that’s ₹40,000/day gross revenue; scaling-up or diversifying adds to income potential.

Conclusion

Installing a notebook making machine in Mago, Arunachal Pradesh is feasible and promising for small-scale manufacturing entrepreneurs. By carefully assessing demand, selecting appropriate machine type (manual / semi-automatic / automatic), ensuring proper site readiness, and leveraging state-level support for MSMEs, you can establish a productive and profitable notebook manufacturing unit.