Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

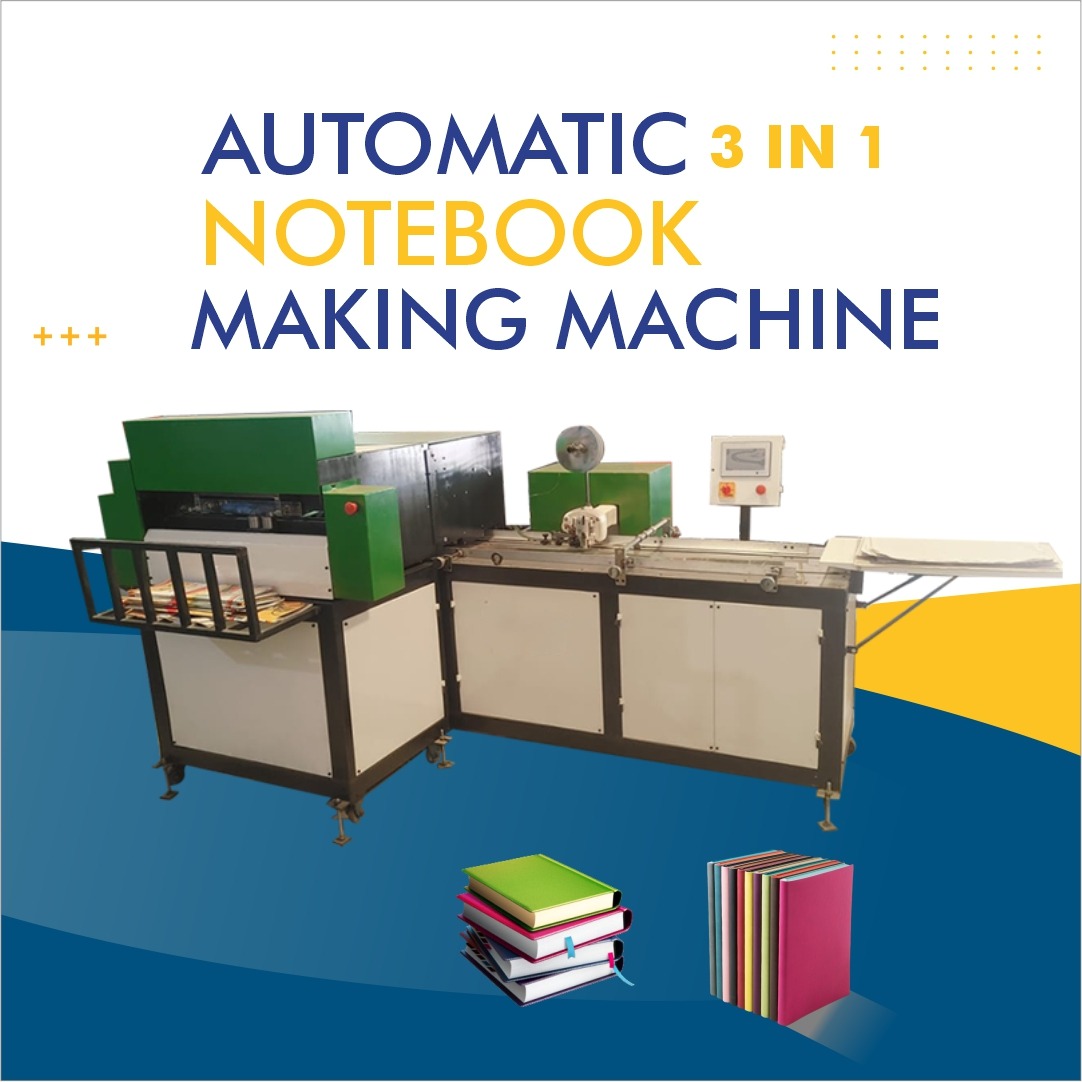

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Lumla | Reliable Manufacturer in Arunachal Pradesh

Notebook Making Machine in Lumla | Arunachal Pradesh

If you are searching for a notebook making machine in Lumla, Arunachal Pradesh, you have come to the right place. Whether you want to start a small stationery business in Lumla or upgrade your existing production line, having the right equipment is essential. Our company specializes in designing, manufacturing, supplying, and servicing notebook making machines suited to the local conditions and business scale. We understand the unique challenges of running manufacturing equipment in Arunachal Pradesh, such as remoteness, power supply constraints, and logistics. Our machines come with robust design, reliable after-sales support, and custom configurations to meet your production goals.

This page will help you understand what types of notebook making machines we offer, why Lumla is an ideal location, what you should consider before buying, and how to get started.

Why Choose Lumla, Arunachal Pradesh

-

Strategic Location: Lumla is one of the border administrative centers in West Kameng district of Arunachal Pradesh, serving nearby rural areas. Local manufacturing can serve remote schools, small stationery outlets, and cottage-scale production.

-

Growing Demand: With increasing awareness of education, many government initiatives, schools, NGOs, and private institutions require stationery locally. Producing notebooks locally can reduce cost, shorten lead times, and meet local demand.

-

Supportive Environment: Arunachal Pradesh is encouraging small-scale industries, cottage and micro-enterprises under state and central government schemes. Manufacturing notebook making machinery or operating it locally may benefit from subsidies or grants.

-

Logistics Feasibility: While remote, Lumla is connected to the district headquarters and benefits from local transport for raw materials like paper, binding boards, adhesives, and for distribution of finished notebooks to nearby schools and customers.

Given these advantages, setting up or sourcing a notebook making machine in Lumla makes sense for entrepreneurs, school cooperatives, or government-supported units.

Types of Notebook Making Machines We Supply

We offer a variety of machines suitable for different scale and automation levels. All are customizable for local voltage, raw material sizes, paper types, and binding materials.

-

Manual / Semi-Automatic Notebook Making Machine

-

Ideal for small units producing limited daily output (e.g. 100–500 notebooks/day).

-

Operated by skilled labor with manual feeding of paper covers, stitching or binding, trimming, and packaging operations.

-

Lower power requirement, lower initial cost, easier maintenance.

-

Best suited in rural or semi-urban settings around Lumla where electricity supply might fluctuate.

-

-

Fully Automatic Notebook Making Machine

-

Suitable for larger-scale production (e.g. 500–3000 notebooks/day).

-

Automates feeding sheets, pressing, stitching or binding (wire-o or perfect binding depending on model), cutting/trimming edges, and auto-stacking.

-

Higher throughput and consistent quality; useful for supplying schools, small publishers, or government-mandated stationery supplies.

-

-

Custom Notebook Machine for Special Formats

-

Custom sizes (A4, A5, custom ruled lines), special covers (hard or soft), eco-friendly recycled paper, or oversized notebooks.

-

Option to include numbering, perforation, embossing, serial-printing features.

-

-

Peripheral Equipment & Spare Parts

-

Paper cutting machines, trimming units, binding wire suppliers, glue application units.

-

Maintenance service contracts specific to Lumla region and replacement parts stocking.

-

-

Upgradable / Modular Notebook Making Equipment

-

Start with a semi-automatic core unit; upgrade later by adding automatic feeder, trimming and packaging modules.

-

Helps scale as your demand grows without purchasing a completely new machine.

-

Key Features & Specifications

When selecting a notebook making machine for use in Lumla or elsewhere in Arunachal Pradesh, consider these features:

-

Production Capacity: Number of notebooks per hour or per day. Choose based on projected demand from local schools, offices, or sales outlets.

-

Format Size Compatibility: A4, A5, custom sheet size. Ability to handle different ruled-line templates.

-

Binding Type: Stitching (wire-staple), perfect-binding (glue), spiral / plastic binding options.

-

Voltage & Power Supply: Machines designed to run efficiently under variable voltage or limited-phase supply common in rural areas.

-

Material Handling: Ability to work with local paper stock (recycled paper, locally purchased sheets), cover boards, and binding materials.

-

Ease of Operation & Maintenance: Given remote location of Lumla, machines should have simple controls, local servable components, and minimal downtime.

-

Dimensions and Footprint: Space availability in workshop or small factory unit.

-

Durability & Climate Adaptation: Arunachal Pradesh has a Himalayan climate; equipment should be corrosion-resistant, robust against humidity, temperature variation, and dust.

-

Automation Level: Decide between manual, semi-automatic, and fully automatic depending on budget, manpower availability, and anticipated production scale.

-

Safety & Compliance: Adherence to Indian safety standards, electrical safety certifications, and operational safeguards.

Benefits of Local Notebook Machine Manufacturing

Choosing a local supplier or manufacturer of notebook making machine in Lumla offers several advantages:

-

Lower Transport Costs & Lead Time: Shipping heavy machinery across difficult terrain to Arunachal Pradesh can be expensive. Local supply reduces freight cost and delivery delays.

-

Faster Service & Support: Local manufacturer or reseller can provide quicker repair, spare-part replacement, and maintenance support.

-

Adaptation to Local Needs: Machines can be customized for local raw materials, educational board specifications, school syllabus-specific ruled lines or cover designs.

-

Boost to Local Economy: Manufacturing equipment locally helps create jobs, supports cottage industries, and aligns with government policies promoting rural industrialization.

-

Compliance & Licensing Ease: Local manufacturing or assembly may simplify regulatory approvals, certification, and eligibility for government-assisted schemes or subsidies.

Cost Considerations & Return on Investment

Before buying a notebook making machine, assess the financial and operational implications:

-

Initial Capital Investment: Semi-automatic machines cost less upfront, while fully automatic models require higher capital but deliver higher throughput.

-

Operating Costs: Include raw materials (paper sheets, cover art board or card stock, glue or staples, binding wire), labor, electricity, and maintenance.

-

Break-even Period: Estimate number of notebooks you must sell / supply per day or month to recover the investment. Consider local market price of notebooks in Lumla or West Kameng district.

-

Revenue Sources: Direct sale of notebooks to schools, stationery stores, government contracts, or procurement through local agencies.

-

Government Schemes & Grants: Check availability of MSME subsidies, rural enterprise grants, or educational supply-chain support in Arunachal Pradesh to reduce costs.

-

Scalability: If you plan to grow production, select machine options that can be upgraded or expanded without full replacement.

How to Procure a Notebook Making Machine in Lumla

If you intend to buy or install a notebook making machine in Lumla or nearby region, follow these steps:

-

Requirement Assessment

-

Define your expected daily/weekly output.

-

Choose paper size formats, binding type, binding volume.

-

Specify your budget, available workshop space, electricity specifications.

-

-

Machine Selection & Demonstration

-

We offer on-site or virtual demo of our machines.

-

You can inspect sample notebooks produced, assess finishing quality, binding strength, and trimming quality.

-

-

Quotation & Customization

-

Submit your project details (quantity, format, automation level) to receive a detailed quotation including machine cost, shipping to Lumla, installation cost, local taxes, and possible subsidy adjustments.

-

-

Delivery & Installation

-

Arrange transportation to Lumla.

-

Our team coordinates shipment, customs (if applicable), local permits, and installation supervision.

-

Training of your staff on operation, preventive maintenance, safety procedures.

-

-

Maintenance & After-Sales Service

-

We provide annual maintenance contracts, spare part supply, remote technical support (phone / video), and periodic service visits as required.

-

We maintain a local liaison for quick response in Arunachal Pradesh.

-

-

Scaling & Upgrades

-

As demand grows, you can upgrade modules (automatic feeders, trimming units, finishing stations) to increase capacity.

-

You may also install numbering or perforation add-ons or switch binding type from wire to perfect binding.

-

Case Study & Success Story (Hypothetical)

To illustrate, imagine a stationery cooperative in a nearby village in West Kameng district installed our semi-automatic notebook making machine. Initially producing 200 notebooks per day for local schools, they later secured a small government contract to supply 5,000 notebooks per month. Having locally-based technical support, they scaled up via an upgrade module to reach 500 notebooks per day, increasing revenue by 120 %. Their investment paid off within 18 months, and local jobs were generated for paper cutting, binding and distribution.

Such a model is reproducible in Lumla, benefiting from lower logistics cost, easier management, and community-driven enterprise growth.

Frequently Asked Questions (FAQ)

Q. Can I use recycled paper stock with the notebook making machine?

Yes. Our machines can be adjusted to work with recycled or non-standard paper thicknesses. We can fine-tune pressure settings, glue or binding parameters to ensure reliable operation with local recycled material.

Q. What is the lead time for delivering a machine to Lumla?

Lead times vary depending on model and customization, but typically range from 6 to 12 weeks including shipping, customs (if parts sourced externally), testing, and installation. Local customization may add a few weeks.

Q. How much power does the machine consume?

Power consumption depends on the automation level and motor ratings. Semi-automatic units may use single-phase or three-phase motors rated between 1 kW and 5 kW, while fully automatic systems may use higher-power motors, servo drives, and control systems. We can provide detailed specifications in your quote.

Q. Are training & support provided on-site in Lumla?

Yes. We include operational training for your staff at installation, and periodic maintenance visits. Remote support via phone or video call is also available for quick troubleshooting.

Q. Can the machine be upgraded in the future?

Many of our models are modular. You can start with a basic feeding and binding unit, then add trimming or packaging modules as needed. Upgrade paths are included in the initial purchase plan to reduce future disruption.

Conclusion

Investing in a quality notebook making machine in Lumla, Arunachal Pradesh is a smart step for any stationery entrepreneur, school cooperative, or small-scale manufacturer. With the right equipment, you can produce high-quality notebooks locally, reduce dependence on distant suppliers, cut shipping cost, support local economy, and take advantage of government incentives for rural manufacturing and education support.