Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

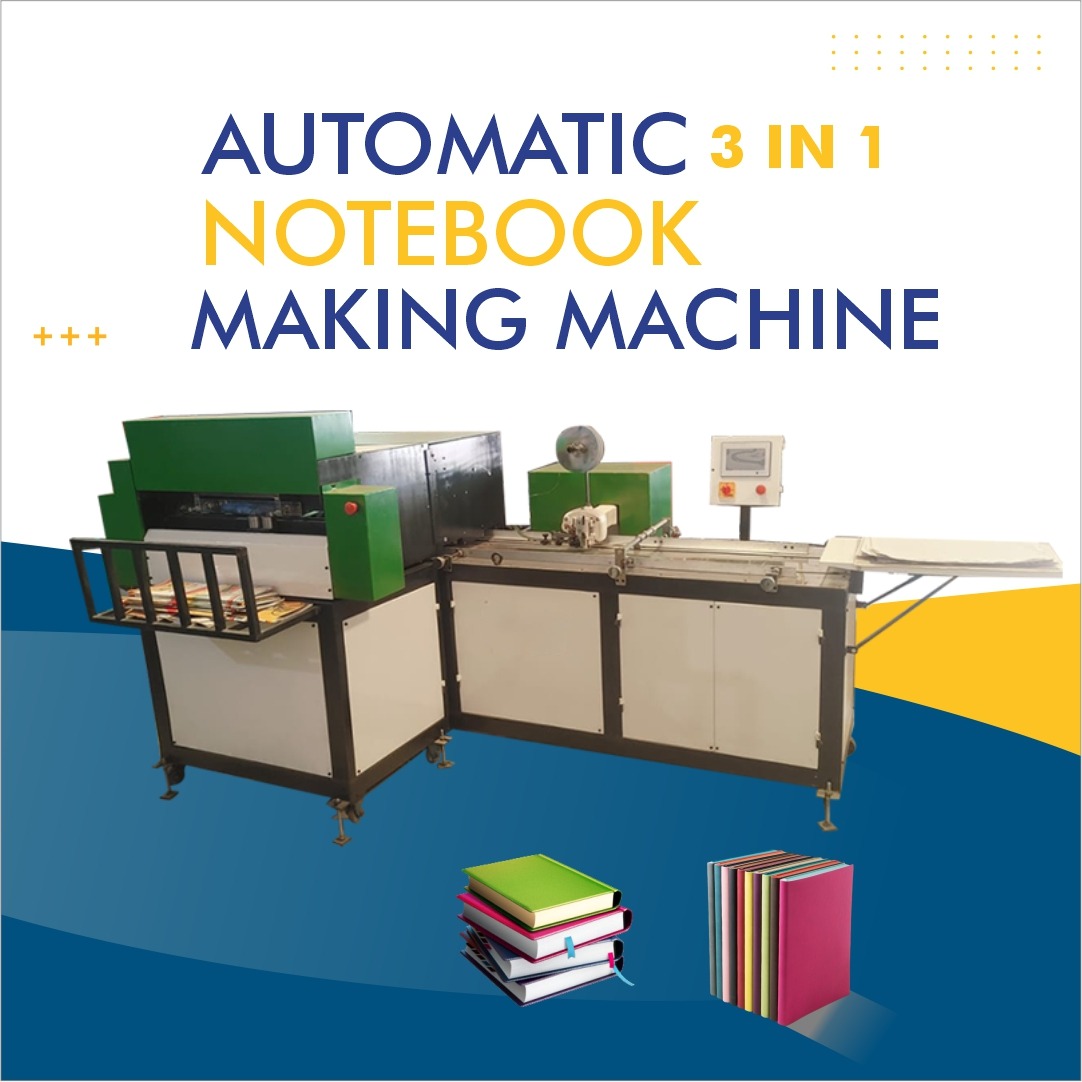

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Mago Arunachal Pradesh

Introduction

If you are searching for a notebook making machine in Kumki, Arunachal Pradesh, you’ve landed at the right place. Whether you plan to start a stationery manufacturing unit, upgrade your existing setup, or service your school or local business, you need reliable, durable, and efficient equipment. A high-quality notebook maker can boost productivity, ensure consistent product quality, and reduce manual labour, allowing you to scale your operations and maintain profitability.

In this article, we explore everything you need to know about selecting, buying, installing, and maintaining a notebook making machine in Kumki, Arunachal Pradesh. You will also find tips on choosing the right model, local service considerations, and cost factors.

Why Choose a Notebook Making Machine in Kumki, Arunachal Pradesh

-

Local Support & Servicing: Procuring a notebook making machine locally ensures that you have access to technicians, spare-parts, and maintenance services within the region. This matters in Arunachal Pradesh, where transport and logistics can be challenging.

-

Reduced Lead Time: You can get installation & commissioning faster when the supplier has or coordinates local delivery to Kumki.

-

Suitability to Regional Demand: The notebook styles popular in Arunachal Pradesh — school notebooks, exercise books, exercise copies — require machines that can handle typical sizes, margin stitching, binding style, and quantities. Purchasing locally ensures better alignment with local product standards and material availability.

-

Cost-Effectiveness: When you order via local channels or regional suppliers, you save on shipping, customs duty (if imported), and handling fees.

Key Features to Look For

To ensure you select the right notebook maker or notebook making machine, consider the following parameters:

-

Capacity & Speed

Decide how many notebooks per minute or per hour you need. Industrial notebook makers may produce from a few dozen to several hundreds per hour depending on model. -

Supported Paper Sizes

Typical sizes include A4, A5, B5, or custom regional sizes. Ensure the machine supports the format most used in Kumki / Arunachal Pradesh. -

Binding Type & Finish

You might need stitched binding, saddle-stitch, perfect binding, or spiral binding. Choose a machine that can deliver your required binding style. -

Power Requirements & Safety

Given power fluctuation in remote areas, ensure the notebook making machine you choose has voltage stabilization or a safe design compatible with local power conditions. -

Durability & Build Quality

Machines built from good steel frame, corrosion-resistant components, and heavy-duty motors will sustain continuous operation under variable climate and usage. -

Automation & Ease of Use

Fully or semi-automatic features reduce reliance on manual labour, lower errors, and improve consistency. Look for features like automatic alignment, trimming, and stacking. -

After-Sales Service & Spare-Parts Availability

Verify if spare-parts are stocked or can be shipped quickly to Kumki or nearby urban centres. Ensure warranty and maintenance contract options. -

Cost & Financing Options

Factor the upfront cost, shipping / freight to Arunachal Pradesh, local taxes, installation fees, and operating cost (electricity, maintenance). Some suppliers may offer EMI or leasing.

Types of Notebook Making Machines

Here are some common types of equipment you may encounter:

-

Manual Notebook Making Machine: Requires human intervention for feeding paper, stitching or binding, trimming edges. Good for small-scale production or schools.

-

Semi-Automatic Notebook Maker: Partial automation in feeding, trimming or stitching. Useful for medium-volume production.

-

Fully Automatic Notebook Production Line: Integrates cutting, page-assembly, binding/stitching, trimming, and packaging. Ideal for large-scale notebook manufacturing units.

-

Binding & Finishing Units: Separate modules for binding, cutting, and laminating covers. Useful if you already have some upstream paper processing equipment.

Steps to Procure & Install in Kumki

-

Define Your Production Target

Estimate daily or monthly volume of notebooks you plan to manufacture. This helps you choose capacity and machine model. -

Survey Local Market & Regulations

Check whether there are local permits or electricity-load regulations applicable in Kumki or the Arunachal Pradesh industrial zone. -

Request Supplier Quotations

Send your specifications (size, binding type, sheet count, speed) to multiple notebook making machine suppliers. Ask for cost of machine, installation, shipping, and training. -

Inspection & Factory Visit (if possible)

If the supplier has a manufacturing plant or showroom nearby (or in neighbouring states), inspect the machine or view video demos. -

Logistics & Transportation

Ensure you plan transportation from dispatch to Kumki. Arunachal Pradesh may have hilly terrain; check that freight delivery is feasible and safe. -

Installation & Commissioning

The supplier should send technicians to your site to set up, calibrate and test the machine with actual notebooks. -

Training Your Staff

Machine operators must be trained in feeding, alignment, maintenance routines, safety rules. -

Maintenance Schedule

Establish periodic servicing: lubrication, alignment checks, tightening fasteners, replacing worn parts. Keep a logbook.

Estimating Costs & ROI

-

Capital Cost: A good-grade notebook making machine may cost anywhere from INR 50,000 for manual/semi-automatic small units to several lakhs for more automated equipment.

-

Operating Cost: Electricity consumption, labour, maintenance spare-parts.

-

Revenue Potential: Calculate revenue from sale of notebooks. Example: if you produce 1,000 notebooks per day, sold at ₹10 profit margin each, that yields ₹10,000 daily profit before fixed-cost amortization. Over time, return on investment may occur within months or a year depending on scale.

-

Break-Even Analysis: Subtract fixed costs (machine cost + setup) from net profit per period to find break-even point.

Challenges & Solutions in Kumki / Arunachal Pradesh

| Challenge | Solution |

|---|---|

| Remote Location & Logistics | Choose supplier that offers door-delivery or has agents near Arunachal; plan for transportation delays. |

| Power Fluctuations | Use voltage stabilizer, UPS, or generator backup; prefer machines with robust electrical safety features. |

| Skilled Operators | Train local staff and maintain simple operating procedures; document operating manual in local language as needed. |

| Raw Material Sourcing | Ensure supply of paper sheets, cover boards, staples or binding materials within or near Arunachal Pradesh to minimize delays. |

Case Example (Hypothetical)

Suppose you are in Kumki and want to establish a small-scale notebook manufacturing unit targeted at schools across West Kameng district. You estimate demand for 20,000 notebooks per month. You choose a semi-automatic notebook maker with capacity of 500 notebooks per hour; operating six hours daily, five days a week. It will require about 120 working hours monthly, producing up to 60,000 notebooks — giving you a buffer above your target. You factor in cost of machine, electricity, operator wages, and project profit margin accordingly. Within 6 to 10 months you recover the investment and start to generate net profit for expansion.

Choosing the Right Supplier

When selecting a supplier for your notebook making machine, check:

-

Supplier’s experience in supplying to North-Eastern states.

-

Installation references or prior shipments to Arunachal Pradesh.

-

Warranty terms and spare-parts delivery time.

-

Availability of training materials or remote support.

-

Optional features: safety guards, automation upgrades, spare-part kits.

Maintenance & Operation Best Practices

To ensure long life and performance of your notebook making equipment:

-

Keep the machine clean from paper dust and debris.

-

Lubricate moving joints, bearings and rails as per manual.

-

Regularly inspect stitching or binding mechanisms for wear.

-

Replace consumable parts (blades, cutters, stapler heads) before they degrade performance.

-

Monitor speed and quality during production; adjust settings if margins are misaligned or binding is loose.

-

Maintain a log of downtime and reasons; analyse for preventive maintenance.

Expansion & Scaling Opportunities

Once you start operations in Kumki:

-

You can expand by adding trimming machines, cover laminating units, or paper cutting machines.

-

Offer customized notebooks (with printed covers, school branding, locally-themed design) to increase value.

-

Collaborate with local schools or educational offices to supply branded notebooks in bulk.

-

Explore export or distribution to neighbouring districts or states in the North-East region.

Conclusion

A well-chosen notebook making machine can transform your stationery business in Kumki, Arunachal Pradesh. From improving production speed to reducing manual labour, ensuring quality, and enabling growth — the right equipment matters. Focus on capacity, build quality, automation level, and after-sales support. Plan for logistics, training and maintenance. With proper investment and management, your notebook manufacturing unit can become a reliable source of income and local employment.