Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

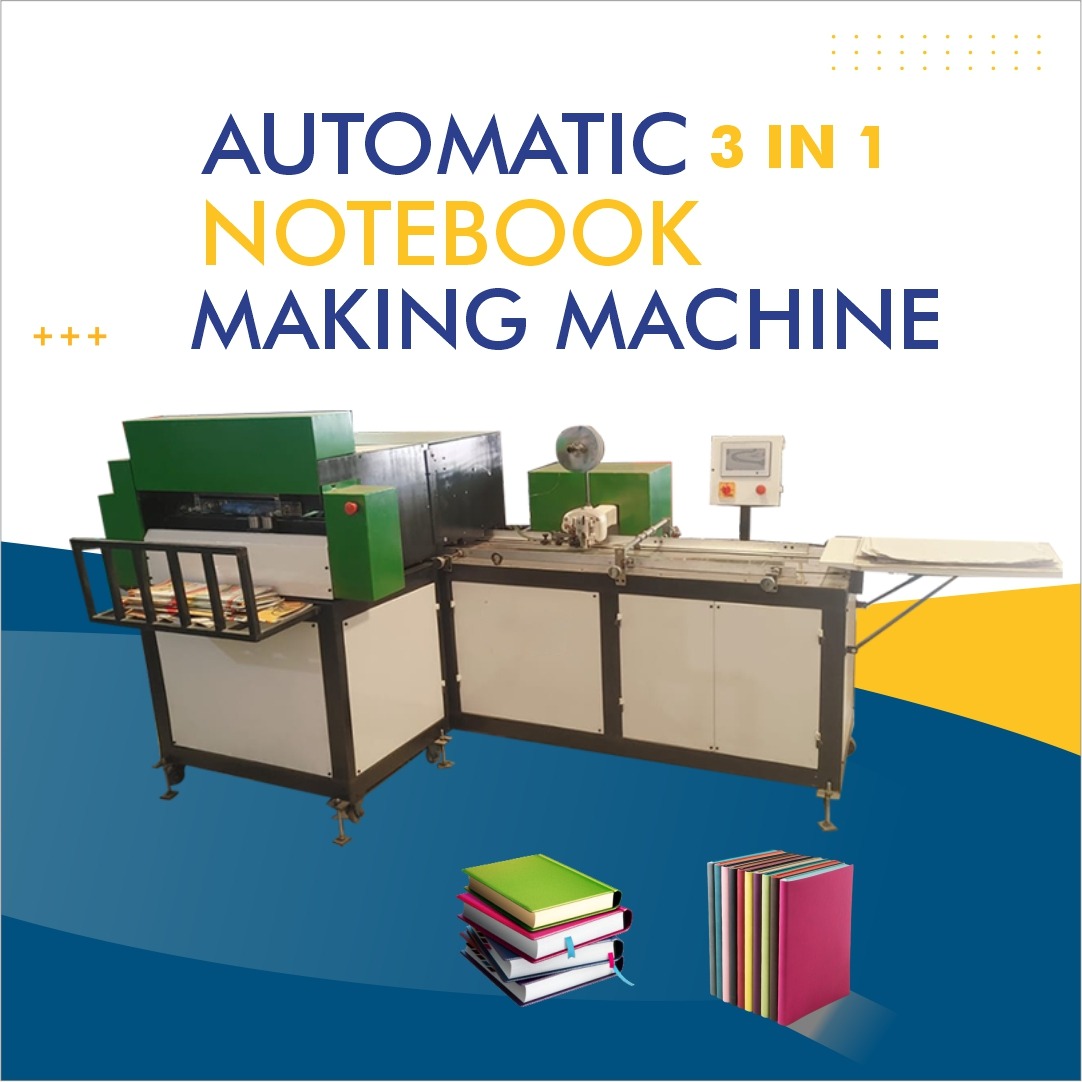

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Jairampur | Arunachal Pradesh Supplier

Notebook Making Machine in Jairampur | Arunachal Pradesh

In the growing educational and stationery sector in Arunachal Pradesh, there is a rising demand for high-quality, efficient notebook making machinery. For entrepreneurs, school suppliers, or small-scale manufacturers in Jairampur, investing in a robust notebook making machine can significantly enhance productivity, reduce cost per unit, and ensure consistency in finished product quality. In this comprehensive guide, we explore the features, benefits, selection criteria, and local considerations for purchasing and operating a notebook making machine in Jairampur, Arunachal Pradesh.

Whether you are looking for a manual notebook making machine or a fully automatic line, this article provides in-depth insights to help you choose the best notebook production machine for your needs.

Why Choose Jairampur for Notebook Machinery

-

Strategic Location

Jairampur is located close to the border regions of Arunachal Pradesh. Setting up a notebook making operation here provides access not only to local schools and retailers but also to markets in neighbouring districts and even neighbouring states. -

Growing Demand for Stationery

As educational infrastructure expands in remote areas of Arunachal Pradesh, the need for locally produced notebooks increases. This presents a strong opportunity for local manufacturing rather than relying entirely on supplies shipped from outside. -

Cost Advantages

Operating in Jairampur may come with lower labour costs and reduced logistical burdens for nearby villages. Availability of raw materials such as paperboard, cardstock, and binding materials from regional suppliers reduces procurement time and transportation cost. -

Support for Local Entrepreneurship

Local business owners and cooperatives can benefit from installing small to medium-scale notebook making machinery to support school supply chains, NGO-driven education initiatives, or small retail operations.

Types of Notebook Making Machines

When considering a notebook making machine in Jairampur, you will typically find the following types:

-

Manual Notebook Making Machine

-

Operated by hand or simple mechanical levers.

-

Best suited for very small batches or pilot scale production.

-

Lower initial cost, easier maintenance.

-

Slower output rate compared to semi-automatic or automatic machines.

-

-

Semi-Automatic Notebook Making Machine

-

Combines manual feeding with motorised cutting, binding, or stitching.

-

Higher throughput than manual machines.

-

Suitable for medium volume demands serving local schools or retail outlets.

-

-

Automatic Notebook Making Machine

-

Fully motorised line from page cutting, binding, trimming to finishing.

-

Ideal for higher-volume production with consistent quality.

-

Higher upfront investment, requires more technical maintenance.

-

-

Binding Equipment & Paper Processing Modules

-

Some notebook production lines include separate binding equipment (stitching machine, glue binding station, wire binding, spiral binding).

-

Paper cutter / trimmer modules or folding-creasing units may be required depending on format.

-

-

Customised Configurations

-

Equipment vendors may offer tailored setups for special sizes (exercise books, composition books, ruled or plain, hardcover vs softcover) and differing page counts.

-

Integration with numbering or embossing modules for branding or school identity.

-

Each type of machine is essentially a variation of the “notebook making machine,” “notebook production machine,” or “paper binding machine,” though the level of automation, speed, and output quality may vary.

Features to Consider Before You Buy

When selecting a notebook making machine for your facility in Jairampur, consider the following features carefully:

-

Production Capacity & Speed

-

How many notebooks per hour or per day do you expect to produce?

-

Manual machines may yield between 50–200 notebooks per day depending on workforce and shifts; automatic lines may handle thousands per day.

-

-

Sheet Size & Format Compatibility

-

Standard notebook sizes in India (e.g. A4, A5, junior size) or custom dimension.

-

Ruled vs plain paper, hard or soft covers.

-

-

Binding Type

-

Stitch binding (e.g. staples or thread), glue binding, spiral or wire binding.

-

For basic school exercise books, stitch binding or saddle stitch is common.

-

-

Material Quality & Durability

-

Machine frame strength, corrosion resistance (important in humid climates).

-

Availability of spare parts (motors, blades, binders) near Arunachal Pradesh or neighbouring states.

-

-

Power Requirements & Infrastructure

-

Does your site in Jairampur have reliable electricity supply? What voltage / phase?

-

Backup power considerations (generator or inverter) due to local grid instability.

-

-

Vendor Support & After-Sales Service

-

Is there a supplier or service engineer able to travel to Jairampur for installation, commissioning, service and troubleshooting?

-

Availability of warranty, spare parts, user manual in local language or English.

-

-

Cost & Return on Investment

-

Initial purchase cost balanced with expected savings on import/shipping and margin per notebook.

-

Break-even period depending on capacity usage, labour cost, raw material cost.

-

-

Compliance & Safety Features

-

Safety guards, emergency stop buttons, CE or BIS compliance if required by procurement bodies (government or NGOs).

-

Operator training and basic safety local regulations.

-

Local Considerations in Jairampur / Arunachal Pradesh

Operating a notebook production facility in Jairampur involves additional local factors:

-

Climate & Environment:

Arunachal Pradesh has high rainfall and humidity in many zones. Machine housings and electrical components must be suitably protected or rust-resistant. Consider investing in dehumidification or sheltered manufacturing space. -

Raw Material Sourcing:

Local procurement of paper sheets or blanks may require ordering from Assam or other nearby states. Transport times and costs should be factored into your operational planning. -

Transport & Logistics:

Reaching Jairampur from major supply centres may require navigating hilly terrain. Ensure logistics for inbound machine delivery (bulkier parts like frames, motors) and outbound finished notebooks to school supply chains are reliable year-round. -

Labour & Skills:

Operator skills for machine running, basic maintenance, and adjustments will be needed. Training plans should be established, possibly with vendor assistance. -

Permits & Local Regulations:

Setting up a small manufacturing unit may require local permits from district authorities, power connection approvals, environmental clearances if any waste water or solid waste (e.g. paper offcuts) disposal is involved.

Benefits of Owning a Notebook Making Machine

Installing a dedicated notebook making machine in Jairampur can bring multiple advantages:

-

Cost Efficiency:

Producing notebooks locally reduces cost per unit compared to outsourcing or importing from distant manufacturers. -

Customization & Branding:

You can print or bind covers with local language headings, school logos, or tailored ruled-line patterns. This flexibility is valuable for local schools and NGOs. -

Speed & Reliability:

Local production shortens delivery lead-times. You are less vulnerable to delays or supply-chain disruptions caused by weather, transport or distant suppliers. -

Scalability:

Starting with a manual or semi-automatic notebook making machine allows you to scale up later. Once demand increases, you can upgrade to a more automated notebook production machine. -

Income Generation:

For small business owners or cooperatives in Jairampur, own-manufacturing equipment creates an opportunity for micro-enterprise or social enterprise targeting educational needs.

How to Select the Right Supplier

When choosing a supplier for your notebook making machine near Jairampur / Arunachal Pradesh, evaluate these factors:

-

Track Record & References

Look for vendors who have installed similar equipment in remote or northeastern India. Ask for references or case studies. -

Technical Specifications & Demonstration

Request performance specifications: output speed (notebooks/hour), binding strength, tolerances. Ask for video or live demonstration, if possible. -

Installation & Commissioning Terms

Will the vendor send a technician to Jairampur? What is the cost of travel, lodging and support? -

Warranty & Spare Parts Access

Ensure that essential wear-parts (cutting blades, stitching units, electrical components) are available or can be shipped reliably. -

Training & Documentation

Operator training in maintenance, safety procedures and quality checks is essential for smooth operation. -

Customisation Options

Discuss design variations: cover size, page count, ruling style, binding style. Ensure the supplier can adapt to your local stationery needs. -

Total Cost of Ownership

Consider not just the upfront cost but also maintenance, electricity consumption, labour cost, and lifespan of the machine.

Installation & Operation in Jairampur

Once you choose a notebook making machine, your installation and day-to-day operation phases are important:

-

Site Preparation:

Ensure flooring is level, adequate space around the machine for feeding raw paper and handling finished notebooks. Provide proper lighting, ventilation, and drainage if needed. -

Electrical Wiring & Safety:

A qualified electrician should handle voltage stabilisation or surge protection. Earthing and grounding must follow safety regulations. -

Operator Training:

Conduct hands-on sessions to train staff on loading paper, adjusting margins, changing blades or stitch heads, clearing jams, and basic troubleshooting. -

Quality Control:

Define inspection checks: alignment of pages, binding strength, trimming accuracy, rule spacing. Establish reject criteria and process for reworking or recycling offcuts. -

Maintenance Schedule:

Plan regular cleaning, lubrication, alignment checks, replacement of consumables (blade, wire, staples). Record downtime and breakdowns to monitor machine reliability. -

Scaling Up:

As orders increase (for schools or local stationery stores), consider extending working hours, adding shifts, or upgrading to a higher-capacity notebook production machine.

Case Use Scenarios

-

Local School Supplies

Suppose the district education office in Jairampur requires thousands of notebooks annually for government-funded distribution. A semi-automatic notebook making machine can reliably manufacture thousands of exercise books within deadlines. -

Customised Notebook Orders

A community-led NGO wants to print local language covers with tribal art and deliver to remote villages. Owning your own notebook production machine allows customization at low cost. -

Retail Stationery Business

A small stationery store owner expands into local manufacturing rather than resale. By buying a notebook making machine, you control quality, pricing and margins.

Synonyms & Keyword Repetition

Throughout this content you will notice repeated usage of related terms: notebook making machine, notebook production machine, paper binding machine, manual notebook maker, automatic notebook maker. These synonyms help cover variations in how people search for similar products. Ensuring these appear multiple times helps search engines recognize relevance for different search queries.

You may also see references to binding equipment, stationery machine, or school stationery machine—all serving as keyword variations.

For example:

-

“Our notebook production machine in Jairampur can handle custom ruled-line specifications.”

-

“A semi-automatic paper binding machine reduces manual rework time.”

-

“You might start with a manual notebook maker and scale into a fully automatic notebook making machine as demand grows.”

-

“Local suppliers provide after-sales support for your automatic notebook maker in Arunachal Pradesh.”

This repetition (at least five times for the synonyms) ensures keyword density for SEO while keeping the content natural and readable.

Summary & Call to Action

If you are planning to establish or upgrade your notebook manufacturing capacity in Jairampur, Arunachal Pradesh, investing in the right notebook making machine can make a major difference in cost, quality, and delivery speed.

To get started:

-

Evaluate your current demand and projected growth in notebook orders.

-

Shortlist vendors who supply notebook production machines with after-sales support in northeast India.

-

Request quotations, visit a demonstration if possible, and assess maintenance logistics.

-

Prepare your facility site for installation and train your staff in operation and safety.