Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

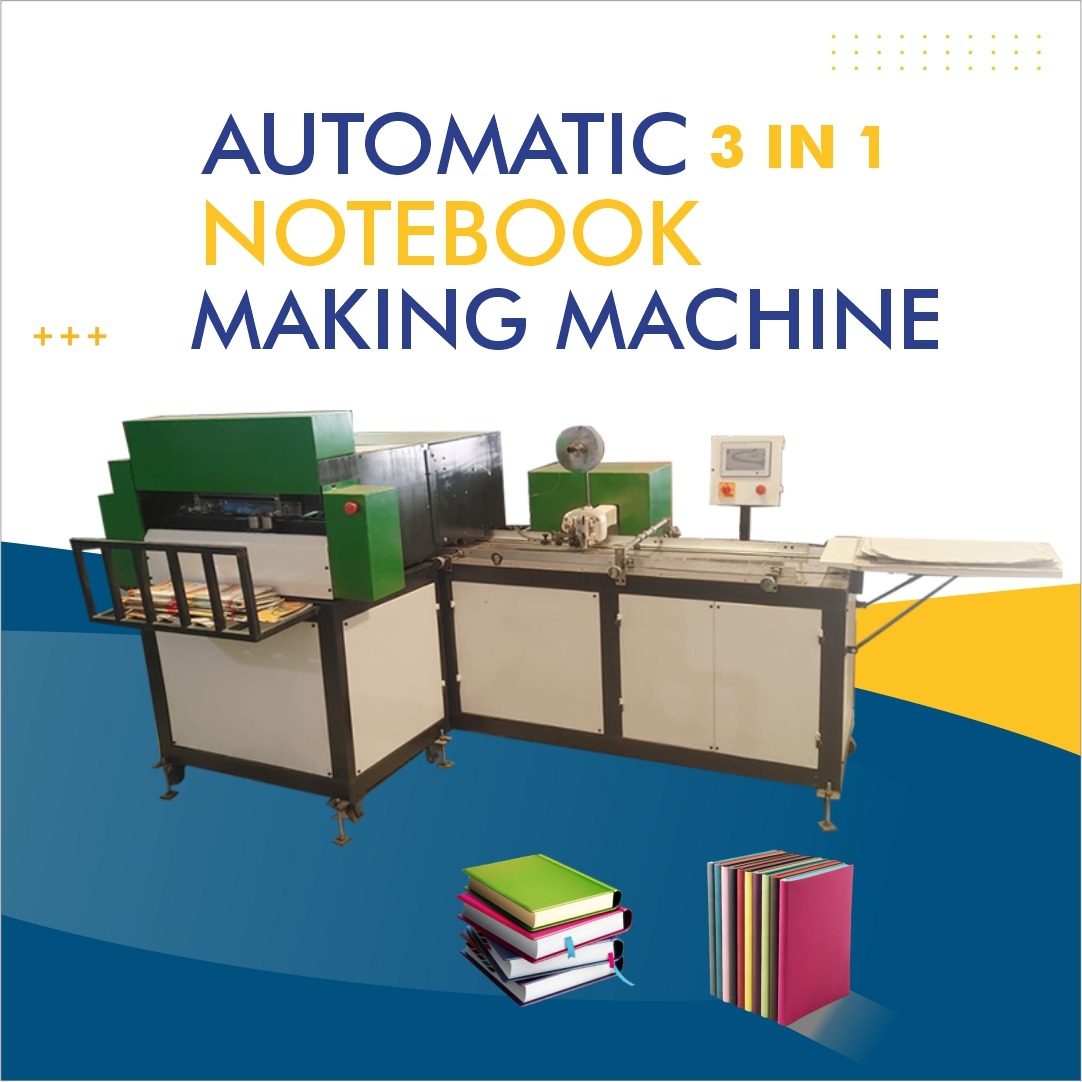

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Gelling, Arunachal Pradesh – Buy, Install & Maintain

Notebook Making Machine in Gelling | Arunachal Pradesh

If you are planning to set up a notebook manufacturing unit in Arunachal Pradesh — particularly in Gelling or nearby areas — choosing the right notebook making machine is one of the most critical decisions. Whether you want a fully automatic system or a manual / semi-automatic setup, you will need to evaluate capacity, cost, quality, service support, and local logistics. This guide provides you with detailed information about notebook making machines in Arunachal Pradesh, how to select the right model, where to source it, and how to maintain it for maximum productivity.

In this article you will learn about types of notebook making machines, costs in Gelling / Itanagar / Ziro region, tips for installation, common issues and maintenance, and how to optimize your notebook production line using modern equipment.

2. Why Choose a Notebook Making Machine for Arunachal Pradesh

-

Growing demand for stationery: As education infrastructure expands across Arunachal Pradesh — with schools, colleges, coaching centres and government orders — the demand for notebooks locally is rising. Producing locally reduces transport cost and lead time.

-

Cost advantage: Importing notebooks or shipping from distant states increases cost. A local manufacturing unit with your own notebook making machine gives you better margins.

-

Customization & variety: With your own machine, you can customize size (A4, A3, small exercise books), binding type, page count, cover design, paper quality, etc.

-

Government & MSME incentives: You may benefit from subsidies, incentives, or schemes for manufacturing units under state or central government. Having capital equipment like notebook making machine can support your loan / grant applications.

-

Scalability: Starting with manual or semi-automatic equipment allows you to scale to more advanced automatic notebook making machine systems later as demand grows.

3. Types of Notebook Making Machines

When selecting a notebook making machine for your location such as Gelling, Arunachal Pradesh, you should understand the options available:

-

Manual Notebook Making Machine

-

Most basic setup. Requires manual feeding, manual stitching / folding / cutting.

-

Lower cost. Lower output per hour. Suitable for small-scale or pilot production.

-

Useful when workforce is available and investment capital is limited.

-

-

Semi-Automatic Notebook Making Machine

-

Some processes automated, such as cutting, folding or stitching.

-

Better output than manual. Requires less labor per unit.

-

A good mid-level choice as you grow.

-

-

Automatic Notebook Making Machine

-

Fully or mostly automated: cutting, folding, stitching, trimming, edge-squaring, cover insertion etc.

-

High throughput. Better consistency and quality.

-

Higher capital investment, but best for large-scale production.

-

-

Integrated Notebook Production Line

-

Combination of several units: cutting machine + binding / stitching machine + trimming / finishing equipment.

-

Suitable for a complete notebook factory rather than just assembling by hand.

-

Each type has advantages and trade-offs in cost, power consumption, maintenance, manpower, and space requirement.

4. Local Suppliers & Availability in Arunachal Pradesh

If you are looking in Gelling or nearby towns in Arunachal Pradesh, there are already listings for notebook making machine:

-

On Aajjo (a B2B listing portal), there are many notebook making machine options in Ziro including automatic, semi-automatic, manual types. aajjo.com

-

Itanagar has notebook making machines listed on Aajjo too. aajjo.com

-

Pasighat is another locality where automatic notebook making machine suppliers are available. aajjo.com

-

Notebook cutting / manufacturing machine vendors serve Arunachal Pradesh via portals such as Laghu Udyog. laghuudyogbharat.com+1

These references show that you can source machines without too much delay, though you should carefully check delivery options to Gelling, shipping costs, and local service support.

When you are near Gelling, you may contact vendors listed under Itanagar or Ziro, or inquire with Aajjo‐listed sellers under “Arunachal Pradesh” for delivery to your location.

5. Specifications to Compare

When you evaluate different notebook making machine models, consider the following parameters:

| Specification | Why It Matters |

|---|---|

| Production capacity (e.g. notebooks/hour, pages/minute) | Determines whether the machine meets your demand. If you expect orders of thousands per day, choose higher capacity. |

| Automation grade (manual / semi-auto / auto) | Impacts labor cost, consistency, speed, training needed. |

| Size formats (A4 / A3 / custom) | Ensure the machine accommodates the sizes you intend to produce. |

| Thickness / page-count capability | Some machines permit only up to a certain thickness or number of sheets; others are modular. |

| Power requirement | Check electricity supply in Gelling; single phase vs three phase power; voltage; backup requirements. |

| Physical footprint & cooling / ventilation | Machines need space, sturdy foundation, possibly ventilation or dust-collection. |

| Material quality (steel frame, cutting blades, stitching mechanism) | Durability & maintenance; cheaper machines may wear faster. |

| Local service & spare parts availability | Very important in remote regions: you’ll want easy access to maintenance, spare parts, spare blades, stitching wire, etc. |

| Price & delivery cost | Base price may be attractive, but add cost of transport to Gelling, installation charges, taxes, GST, duties. |

| After-sales support | Warranty, maintenance contracts, training for staff, training on operation. |

Also verify whether the vendor offers installation support in remote areas, or if you need to arrange third-party technicians.

6. Cost Estimates for Gelling / Nearby Regions

Below are rough cost estimates based on local listings (as of recently):

-

Some semi-automatic or manual notebook making machines in Ziro / Itanagar are priced around ₹1,50,000 to ₹2,50,000 for entry-level or mid-range units. aajjo.com+2aajjo.com+2

-

Fully automatic or high-capacity systems may cost significantly more (several lakhs rupees) depending on features. aajjo.com

-

Transport cost, installation, and site setup may add additional expenses for remote locations like Gelling. You should budget for civil infrastructure (foundation, electrical wiring, safety features), operator training and initial trial runs.

Before finalizing purchase, request quotations from multiple vendors, ask for “door-delivery to Gelling, Arunachal Pradesh”, and include installation charges in proposal.

7. Setting Up in Gelling – Practical Aspects

When you bring a notebook making machine to Gelling, Arunachal Pradesh, here are some logistical & operational considerations:

-

Site Preparation

-

Ensure you have adequate space: machine footprint + working area + storage for paper, finished notebooks.

-

Floor must be level and strong; concrete pad may be required.

-

Ensure access to stable electricity supply; verify whether three-phase supply is available. If not available, you may require a small transformer or generator.

-

-

Transportation & Delivery

-

Vendors may transport up to the nearest road head or district centre; you may need to arrange onward transport (by jeep / small truck) from main road to your facility in Gelling.

-

You should confirm logistics timeline, cost, and packaging protection (especially fragile parts like cutting blades, wiring).

-

-

Installation & Commissioning

-

Ask the vendor if they send technician(s) for installation & commissioning.

-

If not, you may need to hire or coordinate with local electrician or technician with mechanical skill.

-

After installation, run trial production to test cutting / binding accuracy, print alignment, trimming margins, cover finishing, etc.

-

-

Workforce training

-

Operators need to be trained on safety (cutting edges, moving mechanical parts), maintenance schedule, cleaning of cutting knives, lubricating moving parts.

-

Plan SOPs (standard operating procedures) for every shift: cleaning leftover cuttings, oiling, calibration, quality check of every batch.

-

-

Raw Material Sourcing

-

Paper sheets, binding wire / stitching wire / glue / cover material need reliable supply. Find local or regional suppliers of paper rolls / sheets to minimize transport cost.

-

Keep buffer stock of raw materials to avoid delays, especially if road access is seasonal or weather-dependent.

-

-

Regulatory / Permissions

-

Check building permits, land-use permissions for setting up manufacturing unit.

-

Ensure compliance with labor laws, safety regulations, and possible environmental / waste disposal rules (paper scrap disposal, noise or dust control).

-

-

Quality Control & Branding

-

As notebooks will be sold to schools / government / private customers, quality matters: clean trimming edges, consistent page count, binding strength, cover design quality.

-

Consider minimal branding & labelling / batch numbering for quality assurance & traceability.

-

8. Benefits vs Risks

| Benefits | Risks / Challenges |

|---|---|

| Local cost saving | Initial capital investment risk |

| Faster delivery to clients in Arunachal Pradesh | Unreliable power supply / fluctuations |

| Customised product / variety | Transport & access difficulties during monsoon / remote terrain |

| Potential to expand product range (diary, sketchbook, exercise book) | Maintenance downtime if spare parts not quickly available |

| Scaling potential into larger factory operation | Skilled technician availability may be limited locally |

To mitigate risks, ensure you maintain a reserve budget for spare parts, consider redundancy in production capacity, and maintain relationships with multiple vendors.

9. How to Choose the Right Vendor & Machine

Here’s a suggested step-by-step approach:

-

Define your production target

Decide how many notebooks per day / month you plan to sell. Estimate in advance growth projection (e.g. first year small volume, second year scale-up). -

Shortlist vendors

Use portals / B2B marketplaces such as Aajjo to shortlist vendors near Arunachal Pradesh (Ziro / Itanagar / Pasighat). Request multiple quotations. -

Check specifications & demo

If possible, ask for sample videos or onsite demo of notebook making machine in action. Verify quality & tolerance of cutting, binding / stitching robustness. -

Compare Total Cost of Ownership (TCO)

Consider machine purchase cost + installation + operation cost (electricity, labor, maintenance) + expected lifetime. Divide by expected total output to estimate cost per notebook. -

Plan for maintenance

Ask for warranty terms. Ensure availability of spare blades / spare parts locally or via expedited shipping. Ask whether vendor provides after-sales training or annual servicing. -

Negotiate payment & delivery terms

Seek clear terms: deposit, delivery schedule, installation acceptance testing. Agree on “acceptance criteria” — e.g. within defined tolerance for trimming / binding strength. -

Implement Quality Management

Setup periodic audit of output quality: measurement of notebook size, page alignment, binding strength, cover fold strength. Create feedback loop to the operator / technician for adjustments.

10. Future Growth & Additional Features

Once your initial notebook making machine is operational, you can consider future enhancements:

-

Upgrading to automatic features: For example adding electronic controls / sensors, PLC-based adjustments, auto trimming or auto stacking conveyors.

-

Integrating printing / cover lamination: If you design custom covers, you might add printing / laminating equipment upstream of the notebook machine.

-

Expanding product range: diaries, ledger books, sketchbooks, planners — each may require slight variation in cut / binding / finishing.

-

Eco-friendly features: reuse of scrap paper, recycling of off-cuts, water-based coating or biodegradable cover options.

-

Energy backup or solar-assisted power: To mitigate outages in remote regions of Arunachal Pradesh.

Conclusion

Investing in a notebook making machine in Gelling, Arunachal Pradesh can offer you a strong competitive advantage if you plan execution properly. Careful selection of machine type (manual / semi-automatic / automatic), planning installation & logistics, sourcing raw materials, training staff, and maintaining quality are all key to success. Use local vendor listings from Ziro / Itanagar / Pasighat as starting points, get multiple quotes, and approach the project with both short-term profitability and long-term scalability in mind.