Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

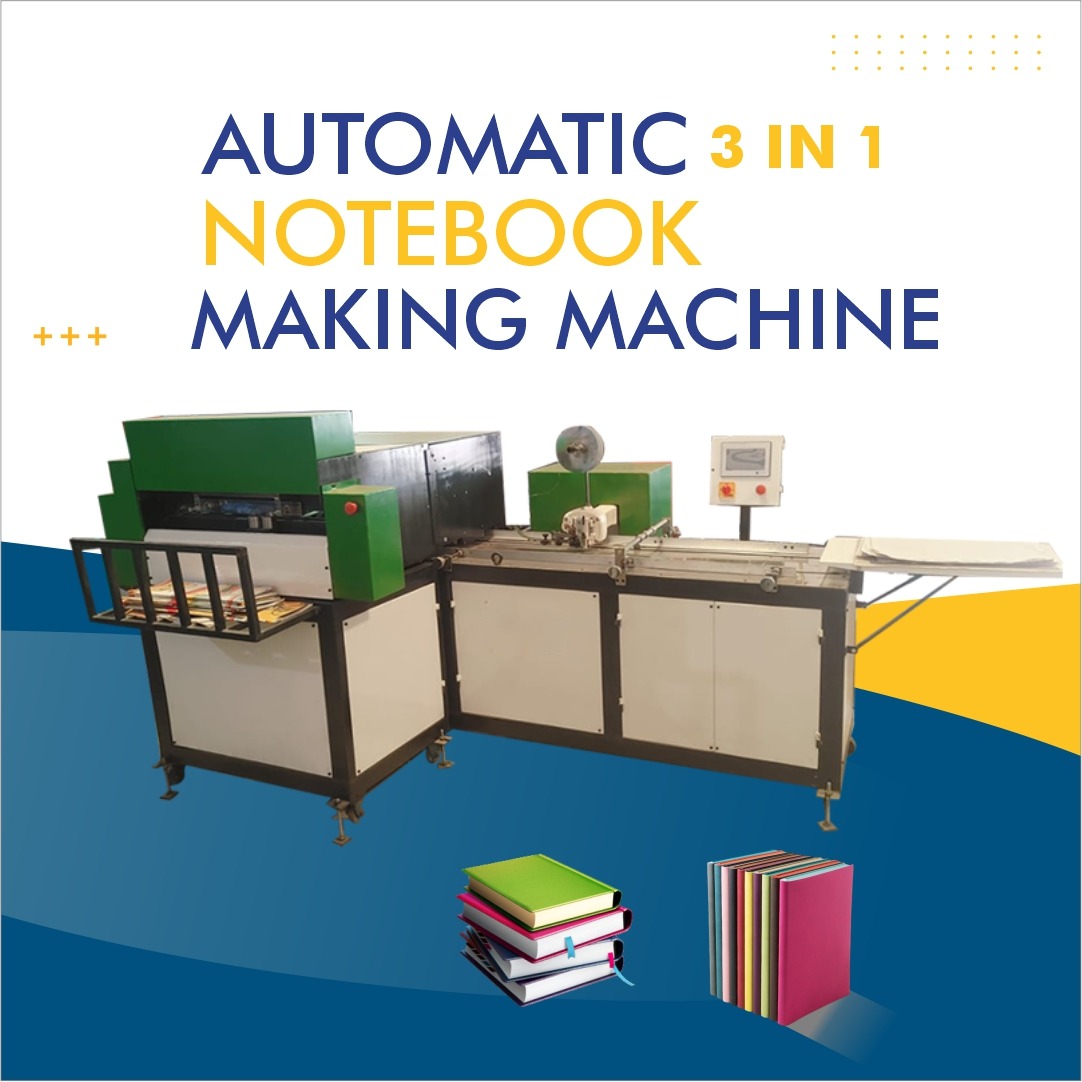

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier & Installation – East Siang, Arunachal Pradesh

Notebook Making Machine East Siang | Arunachal Pradesh

Arunachal Pradesh is increasingly exploring small and medium-scale industries to boost local employment and entrepreneurship. In East Siang district, setting up a notebook manufacturing unit using a reliable notebook making machine presents a promising opportunity. Whether you are an entrepreneur in Pasighat, Mebo or nearby areas, investing in the right machinery can help serve schools, colleges and offices across the region. This article provides a comprehensive guide to setting up a notebook making machine facility in East Siang, including types of machines, cost & installation considerations, regulatory issues, and benefits.

Why East Siang for Notebook Manufacturing?

-

Strategic Location: East Siang is part of Arunachal Pradesh, providing access to both local educational institutions and neighboring northeastern states. Local demand for stationery persists with schools, coaching centres and government offices.

-

Growing MSME Support: The Government of Arunachal Pradesh encourages MSME and small manufacturing units through subsidies, registration schemes, and simplified approvals. Setting up a unit here can benefit from state-level incentives.

-

Lower Competition: Compared to large cities, competition in East Siang is limited, giving early entrants a chance to establish brand presence and supply chains within the district and adjoining regions.

-

Potential for Employment: A notebook manufacturing setup can employ local skilled and semi-skilled labour. This contributes to local economies in villages such as Mirem or other circles around Pasighat.

Types of Notebook Making Machine & Features

To choose the right equipment, it’s important to understand what types of machines are available, and which features matter the most.

| Type | Automation Level | Suitable For | Key Features |

|---|---|---|---|

| Manual / Semi-Automatic | Partial automation | Small-scale startup, limited production | Cutting, manual stitching or gluing, limited speed |

| Semi-Automatic | Motorised assistance | Medium-volume output | Folding, stitching assistance, edge squaring, moderate speed |

| Fully Automatic | High automation | High-volume commercial production | Auto folding, stitching, trimming, edge squaring; PLC-based; high accuracy & output |

Examples of machines in India include semi-automatic or fully automatic notebook making machines from manufacturers like Bhartiya Machine Works bhartiyamachineworks.com, or models by Sujata Machines sujatamachines.in+1.

Key features to check:

-

Production capacity (books per hour)

-

Size variation (A4, A5, custom sizes)

-

Thickness of notebooks (number of pages)

-

Type of binding (wire / stitching / folding)

-

Edge-squaring or trimming capabilities

-

Power requirements (single-phase or three-phase)

-

Automation controls (manual switches or PLC / servo panel)

How Much Does a Notebook Making Machine Cost?

Here are indicative cost ranges based on Indian market data:

-

Basic semi-automatic machines may start from a few lakhs of rupees. smallbusinessolution.com+1

-

Fully automatic machines from established brands cost significantly more (several lakhs to over ten lakhs rupees). bhartiyamachineworks.com+1

-

For example, a single-head automatic notebook stitching / binding machine from Endurance Solutions is priced around ₹9.75 lakh in India. endurancemachinery.com

-

Complex automatic machines with folding, stitching and edge squaring capability may cost more depending on capacity and features. sujatamachines.in

In addition to purchase cost, you may need to budget for shipping (to East Siang), customs / import duty (if applicable), installation labour, civil works / workshop setup, electricity connection cost, and raw material storage area.

Setting Up in East Siang: Practical Considerations

Site & Infrastructure

-

Choose a location with appropriate space (floor area, height clearance), preferably in an industrial / commercial zone near Pasighat or accessible road network.

-

Electricity supply must support the machine’s power load; many heavy machines require three-phase supply. Ensure you coordinate with local electricity board.

-

Floor must be sturdy and leveled; you may need foundation or anti-vibration pads for high-speed machines.

-

Ventilation, lighting, storage for paper raw material, packaging area, loading/unloading access.

Regulatory Approvals & Compliance

-

Register as a business entity (proprietorship / partnership / private limited / MSME registration) with the state authority.

-

Obtain trade license / pollution clearance if required (though stationery units are generally low-pollution, compliance with waste disposal must be ensured).

-

Ensure safety compliance: provision for fire safety, worker safety, local building codes.

Raw Material & Supply Chain

-

Paper sheets / reams: Establish reliable suppliers for paper in required sizes and quality. Transportation cost into Arunachal Pradesh may affect margin.

-

Covers, binding wire / stitches: sourcing binding wire, glue or staples if used. Importing or bulk procurement.

-

Packaging materials: plastic wraps / cardboard packaging for finished notebooks.

Operation & Labour

-

Hire local workforce: machine operators, helpers, quality control staff, packaging staff. Provide training for using automated equipment.

-

Maintenance planning: arrange for spare parts, service support from machinery provider. Some brands provide on-site installation and training (e.g. Bhartiya Machine Works offers training & after-sales support bhartiyamachineworks.com).

-

Power cost, raw-material wastage, rejected units, quality control routines to ensure minimal waste.

Marketing & Revenue Model

-

Identify target customers: schools, coaching centres, local shops in East Siang / nearby districts (e.g. in Pasighat, Mebo, surrounding villages).

-

Pricing strategy: compute cost per notebook (paper cost + labour + power + depreciation of machine + packaging + transport).

-

Volume projection: e.g. if machine makes 1,000 notebooks/hour, and operates 8 hours a day for 25 days a month, you may produce ~200,000 notebooks a month. Adjust for downtime, quality rejects.

-

Packaging & distribution: supply to local retailers, wholesalers, or directly to schools. Explore government tender opportunities for stationary supply in schools.

Advantages & Challenges

Advantages

-

High demand for notebooks in educational sector

-

Opportunity to supply customized sizes / designs for local market

-

Better margins if you cut intermediaries and manufacture locally rather than import or buy from distant factories

-

Creation of local employment and contribution to regional development

Challenges

-

Initial capital investment is significant

-

Logistics & supply chain constraints in a hilly / remote district like East Siang (transport delays, cost of raw materials)

-

Technical maintenance & skilled workforce availability

-

Competition from established stationery brands; you must ensure quality and price competitiveness

Case Scenario – Sample Plan

| Parameter | Estimate |

|---|---|

| Machine Type | Semi-automatic or Fully-automatic notebook making machine |

| Capacity | ~1,000 to 2,000 books per hour |

| Working Hours | 8 hours per day, ~25 days a month |

| Monthly Output | ~200,000 to 400,000 notebooks (depending on hours & efficiency) |

| Revenue per notebook | Suppose ₹30 per notebook (variable depending on cost & margin) |

| Estimated Gross Revenue | ₹6 million to ₹12 million per month (variable) |

| Fixed Costs | Depreciation of machine, interest (if loan), electricity, rent / lease, labour |

| Variable Costs | Paper, binding wire / glue, packaging, transport to retailers |

| Breakeven period | Depends on capital investment; perhaps 6-18 months based on scale & efficiency |

(This is a rough illustrative scenario; you must run detailed cost-benefit analysis with local data, raw material cost & power tariff in Arunachal Pradesh.)

Conclusion

If you aim to launch a notebook production business in East Siang district of Arunachal Pradesh, investing in a quality notebook making machine is the foundational step. Choose the right automation level (semi-automatic vs fully-automatic), evaluate cost vs capacity, ensure regulatory and infrastructure readiness, and build a supply-demand plan targeting local schools and retailers. With proper planning and execution, notebook manufacturing can become a sustainable MSME in East Siang, generate local employment, and meet stationery demand in the region.