Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

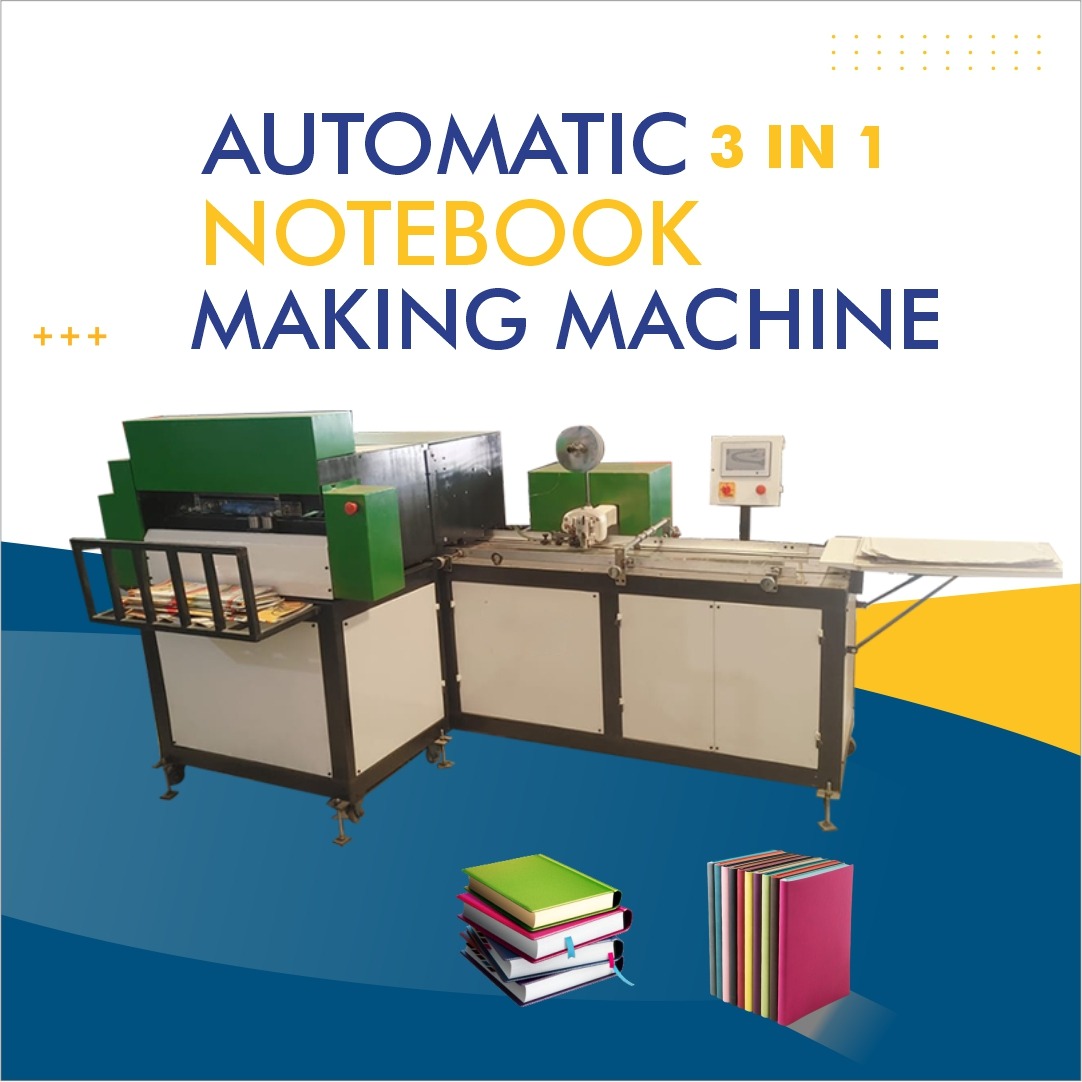

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer & Supplier at Dirang H.Q Arunachal Pradesh

Notebook Making Machine in Dirang H.Q | Arunachal Pradesh

If you are seeking a notebook making machine in Dirang H.Q, Arunachal Pradesh, you’ve come to the right place. Dirang is a scenic headquarters in West Kameng district, and establishing manufacturing operations here can bring multiple benefits — closer access to tribal markets, government incentives for industries in Northeast India, and lower logistics cost for regional demand centres. In this article we discuss types, features, advantages, installation, maintenance, and why your choice of notebook production equipment in Dirang H.Q matters.

This guide also covers how an efficient notebook manufacturing machine setup can boost productivity, cut costs, and deliver quality notebooks tailored to local needs (school exercise books, personalised diaries, custom notepads).

Why Choose Dirang H.Q for Notebook Making Machine Deployment

-

Strategic Location

Dirang H.Q sits in Arunachal Pradesh, offering a gateway for local demand and acts as a node for fostering entrepreneurship in remote Himalayan foothill regions. Having your notebook equipment based at Dirang gives you access to nearby districts, schools, NGOs working in education, and government-funded welfare schemes. -

Lower Operating Overheads

Compared to major metropolitan areas, setting up assembly or small-scale notebook production in Dirang can reduce real-estate / land cost, and enjoy some regional incentives under northeast states policies. -

Growing Demand

Schools, local co-operative societies, and educational institutions in Arunachal Pradesh and nearby Assam may prefer sourcing locally manufactured notebooks to reduce transport cost and delays. -

Support & Service

By positioning your manufacturing machine locally, you can ensure quicker maintenance response, spare-parts supply, and customised support.

Thus installing a notebook making machine in Dirang H.Q is a viable opportunity for entrepreneurs and small-scale industrialists in Arunachal Pradesh.

Types of Notebook Making Machines

To meet varied production requirements, you can consider the following types of notebook manufacturing machines:

| Type | Description |

|---|---|

| Manual Notebook Making Machine | Basic equipment where binding, cutting, folding and stitching are done with significant manual input. Ideal for very small-scale production or training workshops. |

| Semi-Automatic Notebook Making Machine | Machinery automates certain operations (e.g. cutting, folding, pinning), but still needs manual loading or supervision. Offers a balance between cost and productivity. |

| Automatic Notebook Making Machine | Fully automated setup that executes cutting, folding, stitching, trimming, and packaging steps with minimal human intervention. Suited for higher volume production. |

| Spiral / Wire-Binding Notebook Machine | For spiral-bound notebooks, requires specialised stitching or coil insertion units as part of the notebook machine line. |

| Edge-Squaring and Trimming Add-Ons | These modules ensure that the notebook edges are neat and uniform after cutting and binding; often sold as accessories to the main notebook making equipment. |

Each type has trade-offs in speed, cost, labour requirement, and maintenance overhead.

Key Features to Look For

When selecting a notebook making machine for your unit at Dirang H.Q or nearby, consider the following technical and practical criteria:

-

Production Capacity: Measured in notebooks per hour (e.g. 500-5,000 pcs/hr), this determines whether the setup suits low-volume local demand or higher-volume sales.

-

Automation Grade: Manual, semi-automatic or automatic as per your staff bandwidth and budget.

-

Binding Mechanism: Pin/staple binding, wire/spiral binding, or glue binding depending on style.

-

Machine Footprint & Power Requirement: Given Dirang’s terrain and infrastructure constraints, ensure the power supply (single or three-phase), floor area, and ventilation.

-

Material & Build Quality: Stainless steel or heavy-gauge sheet-metal construction ensures durability, especially considering the local climate (humidity, dust).

-

After-Sales Service & Spare Parts Accessibility: Suppliers should provide local servicing or timely delivery of critical parts.

-

Flexibility for Notebook Sizes: A machine that handles multiple formats (A4, subject-notebook size, custom diary formats) gives you business agility.

-

Compliance & Safety: Guards, emergency stops, operator safety compliance as per Indian machinery safety norms.

Advantages & Benefits

Installing a quality notebook making machine in Dirang H.Q brings multiple benefits:

-

Cost Savings: Reduced transportation cost if you supply notebooks to local schools and NGOs in West Kameng and adjoining districts.

-

Faster Turnaround: Local production means you can respond quickly to demand spikes (e.g. before school academic sessions).

-

Customization: Ability to produce personalised notebooks (with logos, customised covers, regional languages) for local institutions.

-

Job Creation: Supporting local labor employment; skill development in machine operation, binding, finishing.

-

Scalability: You can expand from manual to semi-automatic to automatic as demand grows, by incremental investment.

Implementation: From Setup to Operation

Here’s a step-by-step approach to implement a notebook making machine facility at Dirang H.Q:

-

Site Selection & Utilities

Identify suitable workshop space in Dirang H.Q. Ensure electricity (voltage stability), water drainage, proper floor leveling, lighting, and access for delivery of raw materials (paper, covers). -

Procurement & Installation

Source the machine from a reputable manufacturer or supplier (either local or delivered). Check alignment, test runs, calibration of cutting / stitching units. Train operators. -

Raw Material Supply Chain

Establish reliable sources for paper sheets, cover boards, spiral wire (if required), glue/binding staples etc. Possibly from Guwahati / Assam route or regional vendors. -

Operation & Quality Control

Maintain standard operating procedures (SOPs) for quality—alignment, trimming accuracy, binding strength, finish. Monitor rejects and maintenance downtime. -

Licenses, Certifications & Compliance

Ensure you follow any local industrial registration (Udyog / MSME registrations in Arunachal Pradesh), environmental compliance, safety clearance, and signage. -

Marketing & Distribution

Supply notebooks to nearby schools, NGOs, stores; offer customised print or cover design options; build relationships with district education offices. -

Maintenance & Spare Parts

Arrange a schedule for preventive maintenance—lubrication, blade sharpening, machine alignment. Maintain inventory of key spare parts locally (staple wires, cutting blades, belts). -

Scaling Up

As demand grows, you can consider adding more units or upgrading to higher-speed automatic notebook making machine to increase throughput.

Local Considerations & Challenges

Operating a notebook machine facility in Dirang H.Q comes with its specific challenges to be aware of:

-

Logistics: Transporting heavy machinery via hilly roads may cost more or require advance planning.

-

Power Stability: Ensure backup arrangements (e.g. voltage stabilisers or UPS) in case of fluctuations.

-

Skilled Operators: Training local workforce to operate sewing/stitching / binding / finishing modules safely and efficiently.

-

Climate & Environment: Humidity variations may affect paper handling and binding glue performance; choose materials accordingly.

-

Regulatory & Government Incentives: Investigate whether the Arunachal Pradesh government offers incentives or subsidy under MSME or state-industrial development programs for Northeast States.

Being aware and proactive about these factors ensures smooth operation and long-term viability.

Why Partner With Us at Dirang H.Q

If you are considering establishing or expanding your notebook production line in Arunachal Pradesh, we offer:

-

Consultation on choosing the correct notebook making machine model (manual / semi-automatic / automatic).

-

Support for installation, commissioning, and operator training within Dirang region.

-

Local service support and spare-parts replenishment.

-

Advice on upgrading capacity as your demand grows.

We understand the unique geography, transportation constraints, and regulatory environment at Dirang H.Q, and can help tailor a solution accordingly.

Conclusion

A well-chosen notebook making machine at Dirang H . Q, Arunachal Pradesh can act as the backbone of a localised notebook manufacturing business. With the right mix of automation level, quality features, and local support, you can serve educational needs in and around West Kameng district and beyond.

If you’re looking for a reliable supplier, technical specification sheet, or quotation for a notebook making machine in Dirang H.Q, do get in touch. We can help you make the right decision for your scale, budget, and long-term growth