Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

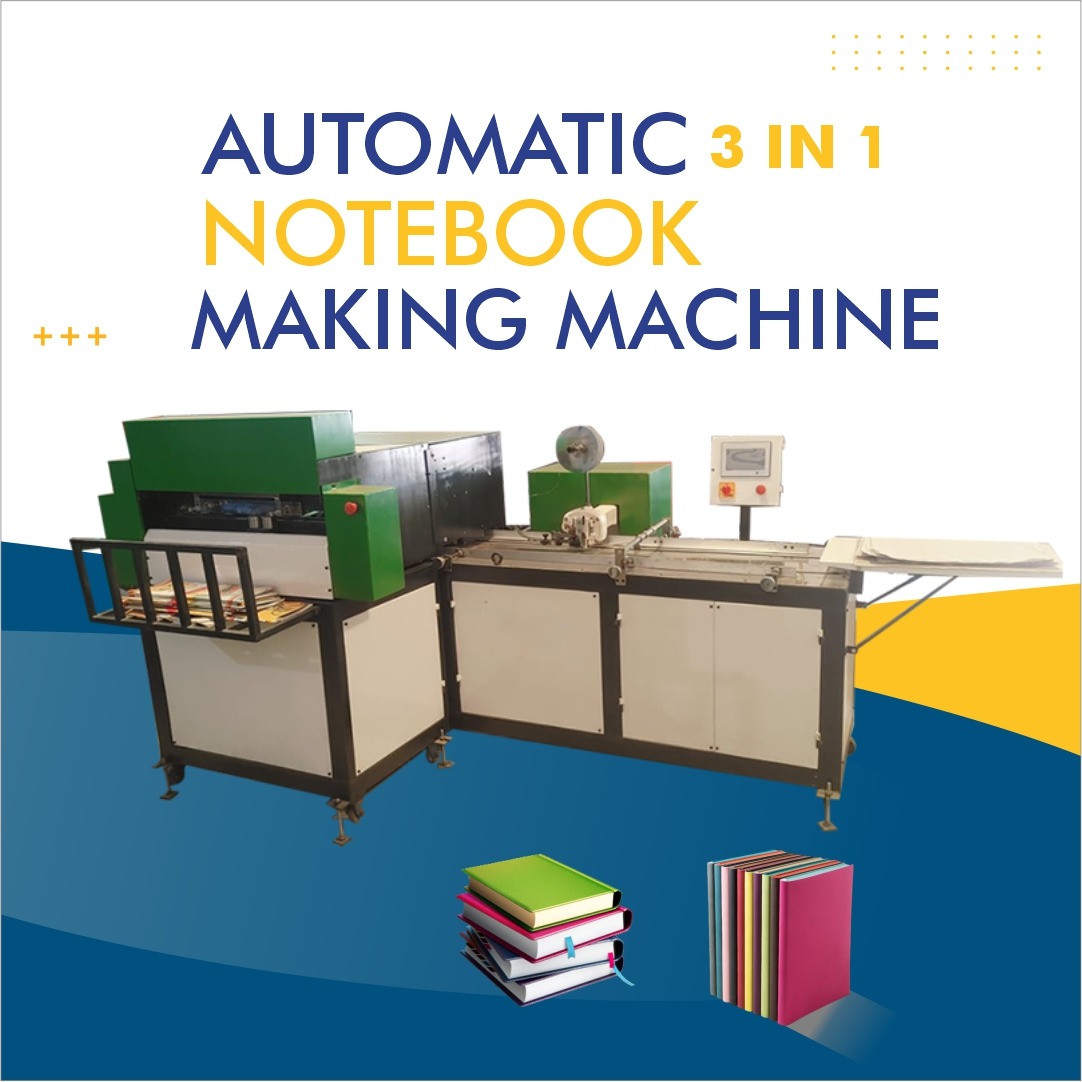

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

High-Performance Notebook Making Machine in Diomali, Arunachal Pradesh — Buy Now

Notebook Making Machine in Diomali | Arunachal Pradesh

In recent years, the demand for stationery products has risen significantly across India, including remote and tribal regions like Diomali in Arunachal Pradesh. Entrepreneurs, small-scale manufacturers, and educational initiatives are increasingly exploring opportunities in notebook manufacturing. Installing the right notebook making machine (whether automatic, semi-automatic or manual) is a crucial step toward setting up a reliable production facility. This article will guide you through everything you need to know about acquiring a notebook making machine in Diomali, Arunachal Pradesh, and how to choose, source, operate it effectively.

This content covers: types of machines, cost and pricing, features, technical specifications, local considerations for Diomali / Arunachal Pradesh, permits & logistics issues, maintenance & after-sales support, and business case for using a notebook making machine in that location.

Why Choose Diomali, Arunachal Pradesh for Notebook Manufacturing?

-

Strategic Location & Resource Potential

Diomali is situated in interior Arunachal Pradesh. Establishing a niche manufacturing unit there can serve both local schools, educational institutions, and also supply stationery to nearby districts. Local sourcing of paper, labour, and potential government subsidies for industry in North-East India may reduce certain costs (transport incentives, tax breaks under NE industrial policy). -

Growing Demand for Stationery

Schools, colleges, coaching centres, and government programmes often require large volumes of notebooks, exercise books, and related stationery. A local production unit powered by efficient machinery like a notebook making machine can fulfil this demand with lower lead time and logistics cost. -

Potential for Government Support & Schemes

Arunachal Pradesh may offer special incentives for MSMEs and manufacturing units under North-East special industrial / infrastructure development schemes. Having a proper machine with compliance may allow you eligibility for subsidies or grants. -

Cost of Logistics & Sustainability

Although transporting raw materials in hilly terrain can be expensive, producing notebooks locally reduces recurring transport cost of finished goods. Moreover, using energy-efficient or local electrical infrastructure reduces total cost of ownership of the notebook machine.

Because of these advantages, investing in a notebook making machine in Diomali is viable if you choose the right machine type, scale, and supplier.

Types of Notebook Making Machines

When selecting a notebook making machine near Diomali, you’ll typically consider three main types:

| Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Manual Notebook Making Machine | Basic machine where operations (paper cutting, folding, stitching / stapling / binding) require manual intervention. | Low cost, simpler maintenance, easier to repair locally. | Lower output, higher labour cost per unit, slower production. |

| Semi-Automatic Notebook Making Machine | Partially automated steps (e.g. cutting, folding or stitching done by machine, but feeding/manual setup required). | Balanced cost and productivity, suitable for small to medium scale. | Still needs operator, may not match output of fully automatic. |

| Automatic Notebook Making Machine | Fully automated line handling paper feeding, cutting, binding/stitching, trimming & finishing. | High output, lower per-unit labour, more consistent quality. | Higher capital cost, requires skilled maintenance and electrical infrastructure. |

Some machines combine sub-functions — e.g. cutting + folding + stitching line — all in one integrated notebook making machine. Endurance Machinery

You may also find specialized versions such as spiral notebook making machines or exercise-book making machines depending on binding style and page formats. asveng.com+1

Key Specifications to Consider

When choosing a notebook making machine, ensure you compare the following specifications:

-

Production capacity (e.g. notebooks per hour or per shift).

-

Maximum binding thickness (number of pages or mm thickness).

-

Paper size compatibility (A4, A5, custom sizes).

-

Speed of cutting / stitching / folding operations.

-

Power requirement (single phase / three phase, voltage, energy consumption).

-

Automation grade (manual / semi-automatic / automatic).

-

Physical footprint and weight (important for installation in Diomali with limited factory floor).

-

After-sales support, spare parts availability.

-

Durability & build material (e.g. mild steel construction, rust resistance due to humidity).

-

Safety features & compliance with industrial regulations.

For example, some semi-automatic notebook making machines have specification such as maximum binding thickness of 20-30 mm, power consumption of a few kW, and capacity in thousands of notebooks per day. asveng.com

Price Ranges & Cost Estimate

The cost of notebook making machines varies widely depending on type and features. Examples from nearby regions (such as Ziro, Pasighat in Arunachal Pradesh) indicate a wide price range. aajjo.com+1

-

Manual models may cost significantly less (₹ 50,000 to a few lakhs), depending on features.

-

Semi-automatic machines: may begin in the range of a few lakhs rupees, increasing with capacity and automation grade.

-

Fully automatic notebook making machines may cost several lakhs to even over ₹10 lakh depending on throughput, capacity, and features. aajjo.com

-

Extra costs to budget for: transportation to Diomali (specialized trucking over hilly roads), installation base (foundation, mounting), local electrical connection upgrades, potential import or shipping costs from manufacturers outside Arunachal Pradesh, consultant fees for installation, and maintenance contracts.

You should request quotations from multiple suppliers, comparing not only price but also delivery time, warranty, spare parts support, and commissioning service.

Sourcing a Notebook Making Machine in Diomali / Arunachal Pradesh

Here is a practical step-by-step approach to sourcing your machine:

-

Define Your Production Requirements

Estimate the volume of notebooks you expect to manufacture daily / monthly. Choose binding style, size formats, thickness, and quality desired. -

Shortlist Suppliers

Use B2B platforms or local machinery dealers in Arunachal Pradesh (e.g. listings in Pasighat, Ziro). aajjo.com+1

Contact them for available models, customisation, shipping to Diomali. -

Request Quotations

Ask for detailed quotations including machine price, installation cost, shipping cost to Diomali, taxes/ duties, warranty, spare-parts policy, and after-sales service. -

Evaluate Power & Infrastructure at Your Site

Ensure your workshop in Diomali has adequate electrical supply (voltage & phases), stable power, and proper floor space. Check whether your building needs reinforcement or foundation for machine weight & vibration. -

Customisation & Local Adaptation

Ask whether the supplier can adapt the machine for local climate (e.g. humidity), local safety standards, or modify feed sizes suitable for your locally available paper sizes. -

Regulatory & Compliance Issues

Since you are in Arunachal Pradesh, ensure you adhere to any local industrial licensing, environmental clearances, and register as appropriate (MSME registration, local district industry office). -

Transportation and Installation

Transportation to Diomali may involve rugged terrain or limited road access. Plan for packaging protection, transit insurance, and onsite labour for unloading & installation. Budget for commissioning engineer / technician to set up the machine and test runs. -

Training & Maintenance

Ensure you receive training for operators and maintenance staff. Keep spare parts inventory locally if possible. Negotiate service-level agreement with supplier for periodic maintenance or breakdown support. -

Trial Production & Quality Control

After installation, run test batches, check binding quality, finishing edges, trimming accuracy, consistency batch-to-batch. Make necessary adjustments before full-scale production.

Advantages of Having a Notebook Making Machine in Diomali

-

Improved Lead Time & Lower Delivery Cost

Producing notebooks locally reduces shipping delays and cost compared to sourcing from distant manufacturers. -

Better Quality Control

With your own machine, you control quality of binding, trimming, finishing, and packaging. -

Business Opportunity & Expansion

You can supply notebooks to schools, NGOs, local government orders, or even neighbouring states. If demand grows, you can scale up by upgrading automation or adding parallel machines. -

Profit Margins & ROI

While capital investment is high initially, over time per-piece manufacturing cost drops. If demand is consistent, you may recover investment within a few months or years depending on volume. -

Employment & Skill Development

Operating machinery locally can employ skilled labour in Diomali, build technical capacity, and possibly contribute to local economic development.

Challenges & Mitigation Strategies

Even though the opportunity is promising, there are challenges when installing a notebook making machine in Diomali / Arunachal Pradesh. Awareness and planning can help mitigate them:

| Challenge | Mitigation Strategy |

|---|---|

| Logistics & Transportation Delays | Plan buffer time for delivery. Choose robust packaging. Use local contact or agent to coordinate transit. |

| Power Fluctuations or Infrastructure Limitations | Install stabilisers / UPS. Coordinate with local electric utility / grid provider. Ensure machine specifications match local supply. |

| Skill Gap / Maintenance Delays | Train local staff, build tie-up with supplier for spare parts. Maintain preventive maintenance schedule. |

| Lower Volume Demand Seasonality | Forecast orders ahead. Align production with school calendars and tenders. Maintain buffer capacity or diversify product line (e.g. different sizes of notebooks). |

| Raw Material Supply Variation | Ensure reliable supply of quality paper and binding materials. Negotiate long-term supply contracts with vendors outside or within Arunachal Pradesh. |

Case Study / Sample Business Plan Sketch

Here’s a rough example of potential usage:

-

Suppose you install a semi-automatic notebook making machine capable of producing 1,000 notebooks per hour, working an 8-hour shift, 22 days per month.

-

Total monthly output = 1,000 × 8 × 22 = 176,000 notebooks.

-

If you sell at a margin of ₹15 per notebook after raw cost and overhead, monthly revenue potential = ₹26.4 lakh.

-

Machine cost plus installation might be ₹5 lakh, yearly maintenance cost perhaps ₹60,000. Within a year or two you may recover capital cost if demand is secured via contracts with schools or government supply tenders.

This shows that an efficient notebook making machine in Diomali can be financially viable if production and sales planning is well aligned.

Conclusion

If you are considering setting up notebook manufacturing in Diomali, Arunachal Pradesh, investing in the right notebook making machine is one of the most critical decisions. You must balance capital investment, production capacity, quality, and local infrastructure. By choosing a suitable model (manual / semi / automatic), sourcing carefully from reliable suppliers, planning installation and maintenance, and aligning your production with demand, you can build a successful notebook production business in this region.