Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

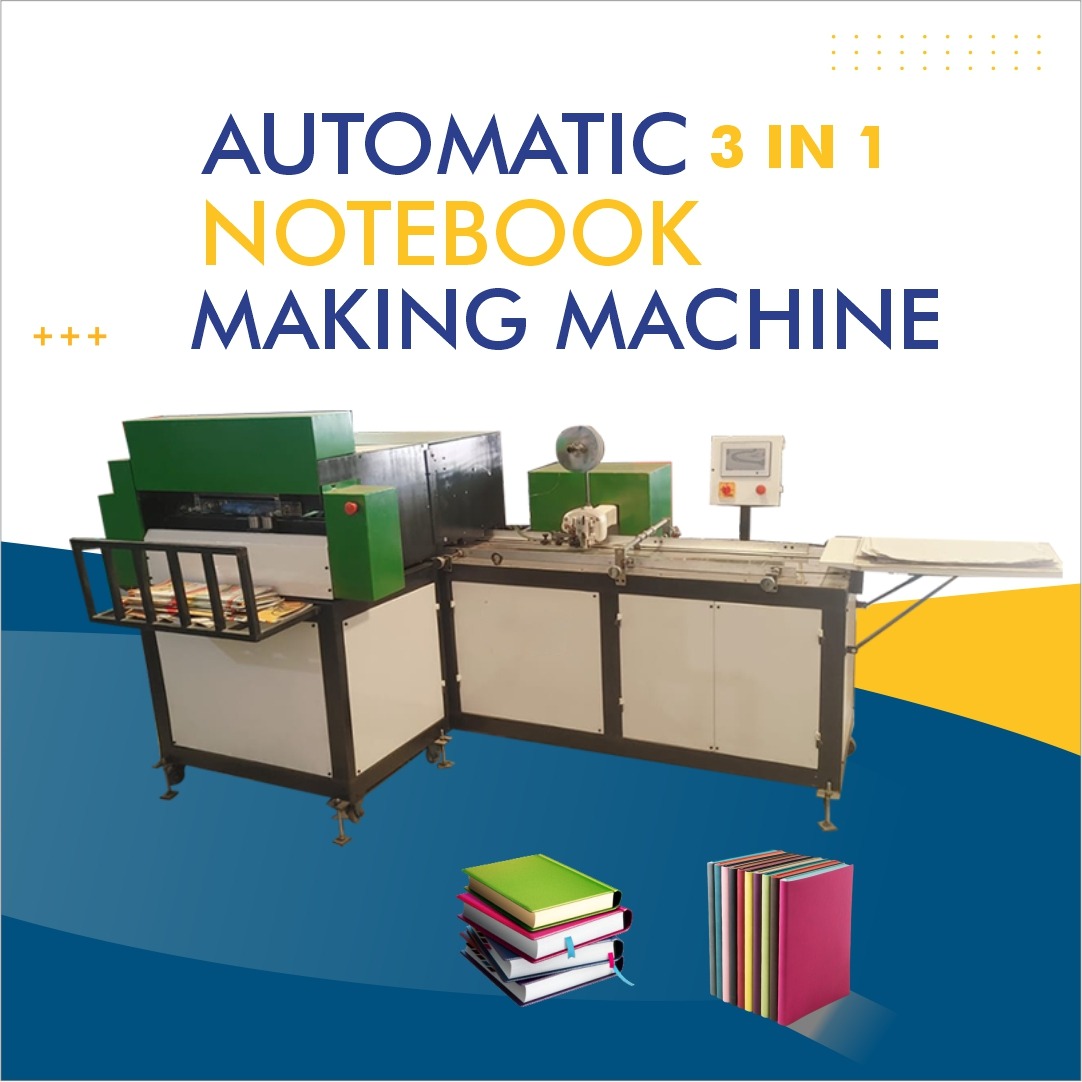

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Daporijo, Arunachal Pradesh | Buy, Install & Maintain

Notebook Making Machine in Daporijo | Arunachal Pradesh

If you’re planning to establish a stationery manufacturing business in Daporijo, Arunachal Pradesh, investing in a notebook making machine is a critical step. With demand for notebooks steadily growing in schools, colleges and offices in Arunachal Pradesh, there is strong potential for local production. A notebook making machine enables you to produce quality notebooks on-site, reduce procurement delays, lower transportation cost, and tap into government / MSME / SHG-support schemes available in the region.

In this article you will learn:

-

What is a notebook making machine and how it works

-

Types & models available

-

Benefits of locating the machine in Daporijo / tribal / remote areas

-

Cost & specifications considerations

-

How to select the right machine / setup

-

Key challenges & advantages for Daporijo, Arunachal Pradesh

-

After-sales support, installation, and maintenance

-

Steps to start production and ensure compliance

Also you will find repeated synonyms for “notebook making machine” such as “notebook production machine”, “book binding machine”, etc, to help with search-engine visibility.

What Is a Notebook Making Machine

A notebook making machine refers to equipment that automates or semi-automates various stages of notebook manufacture: cutting or trimming paper sheets, ruling or perforation, folding, binding (stitching or gluing / wire-stitch), trimming edges, pressing / finishing, and possibly cover binding. Some machines integrate multiple processes under one frame.

Synonyms you may see in machinery catalogs: “book binding machine”, “paper binding machine”, “notebook production machine”, or “automatic notebook machine”.

These machines vary in level of automation (manual, semi-automatic, fully automatic), speed (pieces per hour), supported notebook sizes (A4, A5, custom), and binding technique (staple / wire-stitch / glue-binding).

Modern notebook machines may have PLC (programmable logic controller) control panels, adjustable formats, servo motors for precision stitching, and safety features. For example, single head automatic notebook machines used in binding houses can stitch, fold and trim in one pass. endurancemachinery.com

Why Choose Daporijo, Arunachal Pradesh as Location

Selecting Daporijo (in Upper Subansiri district of Arunachal Pradesh) for setting up a notebook manufacturing unit via a notebook making machine has multiple strategic advantages:

-

Proximity to Local Demand

Local schools, colleges, coaching centres and government offices require notebooks and registers. Manufacturing locally reduces logistics time and cost, and offers quicker supply. -

Accessibility to Government Schemes & Subsidies

Arunachal Pradesh has various MSME, SHG, tribal development and North-East region support schemes. Locals may benefit from subsidies, softer financing for machinery purchase, and easier compliance due to local presence. -

Reduced Transportation Complexity

Importing stationery from far away adds freight cost and delays (especially in hilly terrain). A local production unit using a notebook making machine lowers dependency on external suppliers. -

Local Employment & Skill Development

Operating a notebook production machine unit provides local jobs: operators, machine maintenance staff, quality check, packaging & distribution. -

Potential for Customization & Branding

You can target notebooks with designs resonating with Arunachal’s tribal art, local language labels etc. That gives an edge over generic notebooks imported from outside. -

Competitive Advantage in North-East Region

If you supply to nearby districts, border areas, or even cross-border (where permitted), being based in Daporijo reduces lead time compared to units based faraway in Assam or other states.

Types & Models of Notebook Making Machines

When you plan procurement, you must decide which kind of notebook production machine suite your operations. Some typical kinds:

| Type | Description |

|---|---|

| Manual or Semi-Automatic Machine | Lower cost; requires manual feeding, folding or stitching. Suitable for small-scale production. |

| Fully Automatic Notebook Machine | Integrated line that can perform cutting, ruling, folding, stitching, trimming, and pressing with minimal manual intervention. Higher throughput. |

| Single-Head Automatic Binding Machine | Suitable for binding via stitching / wire-stitch process; used in many commercial setups. endurancemachinery.com |

| Electric / Compact Notebook Machine | Lower footprint; moderate speed; suitable for startup units. TradeIndia |

Key specifications to compare: production capacity (notebooks/hour), supported sizes (A4, A5 etc), binding type (stitching, glue, binder), automation grade (manual / semi / fully), power supply (single / three phase), local voltage compatibility, maintenance requirements.

You should also evaluate cost & supplier reliability. For instance, some machines listed on Indian directories (e.g. TradeIndia) show electric notebook making machines in the price range of lakhs of rupees depending on model and capacity. TradeIndia+1

Cost, Specification & Budget Planning

When procuring a notebook making machine for Daporijo, keep these factors in mind:

-

Machine Price: Depending on capacity and automation, cost could range from a few lakhs to several lakhs. Example machines on online directories show prices like INR 4,10,500 for an automatic notebook machine. TradeIndia

-

Installation & Transport: Add cost of shipping the machine to Daporijo (road transport through hilly terrain), customs (if imported parts), packaging and site preparation.

-

Power & Infrastructure: Ensure stable electricity supply (single or three-phase), space for installation, ventilation, safety guards.

-

Operator Training: Local staff may need training on machine operation, maintenance and safety procedures.

-

Consumables & Spare Parts: Also budget for paper stock, wire staples / binding material, glue or adhesives, and procurement of spare parts locally or via supplier.

-

Regulatory Compliance: Obtain necessary approvals or registration (MSME registration, local trade license, environmental norms if any).

Create a cost-benefit projection: monthly throughput × selling price per notebook minus raw materials, utilities, labour & machine depreciation. Ensure you reach breakeven within a viable timeframe (6-12 months or as per your business plan).

Setup Process & Requirements

Here’s a suggested step-by-step process to install and start a notebook production unit using a notebook making machine:

-

Site Selection & Space Planning

-

Allocate sufficient floor-area in Daporijo (or nearby town), ensure structural stability, flooring, lighting.

-

Ensure entry point for the machine delivery (doorway / road access).

-

-

Power & Utility Setup

-

Arrange for required electric supply (voltage, phases).

-

Backup power (generator / UPS) if region has frequent outages.

-

-

Machine Procurement & Delivery

-

Contact reliable suppliers offering delivery to remote / hilly regions.

-

Confirm warranty terms, after-sales service coverage in Arunachal Pradesh or nearby states.

-

-

Installation & Commissioning

-

Supplier or technician installs the machine, calibrates settings (paper size, binding tension etc).

-

Perform test runs with trial batches.

-

-

Operator Training

-

Train local personnel on safe operation, cleaning, maintaining, and troubleshooting of the notebook production machine.

-

-

Raw Material Sourcing

-

Identify sources of paper sheets, covers (cardboard / printed covers), adhesive or stitching wires locally or via upstream suppliers.

-

-

Production Planning

-

Define product range: e.g. school exercise notebooks, lined / unlined pages, custom cover designs, daily journals etc.

-

Establish quality control procedures (page alignment, binding durability, trimming accuracy).

-

-

Packaging & Distribution

-

Package notebooks (wrapping, bundling), labelling, brand identity with local elements.

-

Distribution plan: supply to schools, stationery shops, local government tenders, or nearby districts.

-

-

Marketing & Compliance

-

Obtain necessary licenses (MSME registration, tax registration etc).

-

Promote your brand in Arunachal Pradesh by highlighting “Made in Daporijo / Local Stationery Manufacturer”.

-

-

After-Sales & Maintenance Plan

-

Schedule periodic maintenance checks (lubrication, belt tension / stitch calibration).

-

Keep documentation of machine performance; maintain logs of breakdowns & spare part consumptions.

-

Challenges & Mitigation

Operating a notebook making machine unit in a remote location such as Daporijo may involve challenges, but each has mitigation strategies:

| Challenge | Mitigation |

|---|---|

| Power instability or frequent outages | Install backup generator or UPS systems; work with energy providers to ensure stable supply |

| Transportation delays / high freight cost | Optimize bulk delivery of raw materials; coordinate with local logistics vendors; consider sourcing some materials closer |

| Skilled labour shortage | Conduct training programs; partner with local skill-development agencies or polytechnic colleges (e.g. technical institutes in Arunachal Pradesh) |

| Higher cost of spare parts or delayed service | Choose a supplier who provides spare-parts support in North-East India, or keep inventory of critical spares |

| Regulatory / compliance delays | Work with local government / municipal bodies early on; ensure MSME / SHG registration to gain support or subsidies |

Despite these challenges, the advantages—lower lead time, local brand appeal, potential subsidy support—can outweigh the costs once production is scaled.

Case Uses & Opportunities

Here are some use-cases and opportunities you may exploit once your notebook making machine is functional in Daporijo:

-

Local School Supply Contracts

Pitch your notebooks to government schools or private schools in Upper Subansiri and neighbouring districts. Government tenders may require stationery supplies. -

Customised Notebooks for Local Markets

Offer covers with local tribal art, bilingual labels, or custom page formats for coaching centres. Unique differentiation helps you compete even against imported notebooks. -

Bulk Supply to Government Offices

Government departments often need stationary in bulk. Being local gives you speed, lower freight cost and easier compliance. -

Expansion to Nearby Towns / States

Once established in Daporijo, you could serve nearby districts in Arunachal Pradesh or even border-region markets, leveraging your local brand presence. -

SHGs or Cooperative Models

You could operate as a cooperative / SHG-linked production unit. Local women’s groups or community organisations might be able to partner, reducing individual capital burden and increasing community development impact.

Why Invest in a Notebook Production Machine Now

-

Demand for quality stationery remains evergreen; schools and educational institutions always need exercise books, registers, diaries, etc.

-

Import delays and rising transportation costs make locally manufactured notebooks more competitive.

-

Indian Government’s push for self-reliance, Make-in-India, and regional entrepreneurship is favourable to small manufacturing units.

-

With proper planning and quality control, ROI for a notebook production machine can be realized within 12 to 24 months from startup.

By situating your production in Daporijo, you combine the social benefit of job creation with the commercial benefit of serving niche markets with lower operational cost.

Conclusion

Setting up a notebook making machine unit in Daporijo, Arunachal Pradesh is a viable venture provided you select the right machine model, plan infrastructure & utilities, navigate local regulation, and manage supply chain for raw materials and after-sales support. The benefits in terms of local demand fulfilment, reduced logistics cost, community benefit, and potential subsidies / scheme support make this an attractive business opportunity.