Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

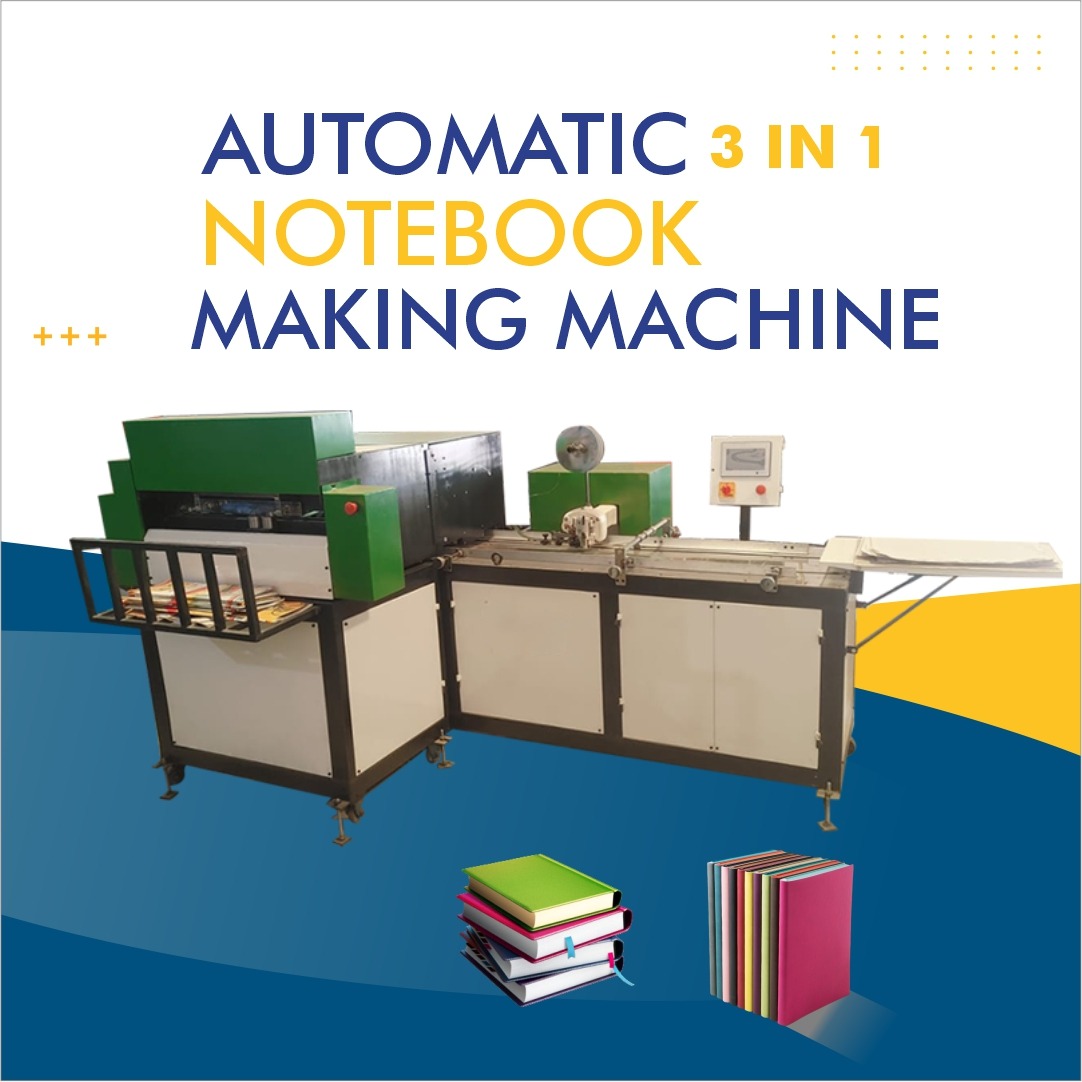

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine – Chawkham, Arunachal Pradesh | High-Quality Machinery

Notebook Making Machine Chawkham | Arunachal Pradesh

If you are planning to set up a notebook manufacturing unit around Chawkham in Arunachal Pradesh, choosing the right notebook making machine is vital. Whether it's manual, semi-automatic or fully-automatic equipment, quality machinery determines your productivity, cost-effectiveness, and long-term success. This page provides detailed information about notebook making machines, their features, types, benefits, and how you can source or install one in Chawkham, Arunachal Pradesh.

In this comprehensive guide you will learn:

-

What is a notebook making machine

-

Types & automation levels

-

Key specifications & capacity

-

Local considerations in Chawkham / Arunachal Pradesh

-

Supplier & maintenance considerations

-

Cost & ROI estimation

-

How to proceed with procurement

This content incorporates popular keywords such as notebook making machine, notebook manufacturing machine, automatic notebook machine, and others to help you with SEO visibility.

What is a Notebook Making Machine

A notebook making machine is industrial equipment used to assemble blank notebooks with features such as cutting, stitching or binding, folding, edge squaring, and finishing. These machines automate or semi-automate tasks in bookbinding and stationery production. The core processes include:

-

paper cutting

-

stitching or binding (e.g. wire stitching, thread stitching)

-

folding or creasing

-

edge squaring (to give tidy edges)

-

trimming and finishing

Depending on your scale of production, you may choose a manual, semi-automatic or fully automatic notebook making machine.

Types of Machines & Automation Levels

Here are the typical categories you might consider:

-

Manual Notebook Making Machine

-

Operated largely by hand or foot-operated mechanisms.

-

Suitable for small‐scale production or startup units.

-

Lower cost, easier to maintain, but slower throughput.

-

-

Semi-Automatic Notebook Making Machine

-

Combines motor-driven components for paper cutting, stitching or folding, but still requires operator intervention for loading or alignment.

-

Higher capacity than manual machines; better consistency.

-

Example: a semi automatic notebook making machine with capacity up to ~5,000 pieces per day. asveng.com+1

-

-

Fully Automatic Notebook Making Machine

-

Integrated automation across cutting, binding, folding and finishing with minimal manual intervention.

-

Highest throughput, consistent quality, and ideal for large-scale production.

-

Example: fully automatic machines with production capacity of ~9,000-10,000 notebooks/day and heavier machinery specs. royalbusinessindustry.com+1

-

-

Specialised Binding / Stitching / Edge-Squaring Machines

-

These may not form the whole line but serve as additional modules (e.g. edge squaring unit, stitching / folding combined machine). shkimachinery.com

-

When choosing the type, you should match your intended daily volume, manpower availability, power supply and budget.

Key Specifications & What to Look For

When evaluating a notebook making machine in Chawkham / Arunachal Pradesh, focus on these parameters:

-

Production capacity: How many notebooks per day or per hour (for example 3,000/day, 5,000/day, or up to 9,000-10,000/day). royalbusinessindustry.com+2sbsmachine.com+2

-

Automation grade: Manual / Semi-automatic / Fully automatic

-

Power requirements: Voltage (single or three phase), motor power (e.g. 2 kW, 3 kW, 5 HP etc.). sbsmachine.com+1

-

Machine size & weight: Heavier machines may require structural support or flooring. royalbusinessindustry.com+1

-

Paper size & format: Maximum cutting width / sheet size (e.g. 32", 33", 35", 36"), thickness of notebooks. asveng.com+1

-

Build material & durability: Mild steel frame, precision components, resistance to humidity or environmental factors (especially in hilly or remote areas).

-

After sales & maintenance support: Spare parts availability, service technicians, supplier reliability.

-

Footprint & infrastructure: Floor space needed, power availability, ventilation, operator space.

Also consider cost of ownership: initial purchase cost, transportation, installation, utilities (electricity), maintenance, and expected lifespan.

Local Considerations: Chawkham, Arunachal Pradesh

Since you’re based in Chawkham, Arunachal Pradesh, there are some special factors you should plan for:

-

Logistics & Transportation

-

Machines will likely come from outside the region. Transport cost and route access (road condition, weight limits on bridges, customs or state-approvals) may affect delivery time and freight cost.

-

-

Power Supply

-

Ensure stable electricity supply. High-power machines may require three-phase supply or stable voltage regulation depending on your location.

-

-

Skilled Operator & Labor

-

For semi or fully-automatic machines, you will need staff trained in operating and maintaining the equipment. Consider training or hiring technicians.

-

-

Environmental Conditions

-

Humidity, temperature fluctuations, dust or rain may affect machine performance. Proper enclosure or shed design may be required.

-

-

Permits & Local Regulation

-

Check local business registration, factory licensing or pollution-control norms if water/air disposal or noise is relevant.

-

-

Access to Spare Parts & Service

-

Choose a supplier who either provides on-site service or shipping of replacement parts to Arunachal Pradesh. Delays in spare part supply can stop production.

-

-

Market Demand & Raw Materials

-

Availability of paper, packaging materials locally; demand from schools / stationery shops in nearby districts.

-

Supplier & Procurement Strategy

When acquiring a notebook making machine for your unit in Chawkham:

-

Research Suppliers

Search for Indian manufacturers or distributors of notebook making machines who support delivery to Arunachal Pradesh. Get quotations for manual, semi or fully automatic versions. -

Request Demos or Case Studies

Ask for reference installations in similar terrain or region. -

Compare Multiple Quotes

Consider different models – check the trade-off between upfront cost and production capacity. A semi-automatic machine may cost less but slow down your business growth compared to investing in fully-automatic later. -

Planning Installation

Ensure site preparation: stable concrete floor, proper electrical wiring (voltage, phase), ventilation/light access and security. -

Maintenance Plan

Plan for regular servicing, lubrication, calibration. Neglecting maintenance can degrade productivity or produce defective notebooks. -

Scaling Up

Choose machine models that can be upgraded or expanded (e.g. additional stitching heads, optional modules) as your demand grows.

Cost & ROI Estimation

Here’s a sample way to estimate ROI for a notebook making machine in Chawkham:

| Item | Estimate |

|---|---|

| Machine Cost | Rs X lakhs (depending on model / capacity) |

| Freight & Installation | Rs Y lakhs (transport + setup) |

| Daily Production | e.g. 5,000 notebooks / day |

| Selling Price per Notebook | e.g. ₹10 per notebook |

| Monthly Sales Revenue | 5,000 × 25 days × ₹10 = ₹1,250,000 |

| Operating Costs | Electricity, labor, maintenance |

| Break-Even Period | (Machine + installation cost) ÷ (monthly profit) |

You should run your own numbers based on your local labor cost, electricity tariff in Arunachal Pradesh, raw-material price etc.

Why Choose Us / Local Advantage

If you set up your notebook production with a reliable machine in Chawkham:

-

You can supply stationery to local schools & shops across nearby districts without heavy transport costs.

-

You can offer customized notebook sizes or branding to local customers.

-

Your “Made near me” advantage may appeal to buyers concerned about quick delivery and lower shipping overhead.

-

Potential for expansion into related paper-product lines (registers, diaries).

Selecting the right notebook making machine with capacity and reliability will help you achieve productivity, consistent quality, and profitability.

Conclusion

Choosing the right notebook making machine for a business in Chawkham, Arunachal Pradesh involves balancing your production targets, budget, and local factors such as power supply, transportation and maintenance. Whether you begin with a semi-automatic setup and scale later, or invest in a fully-automatic line from the start, careful planning is key.