Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

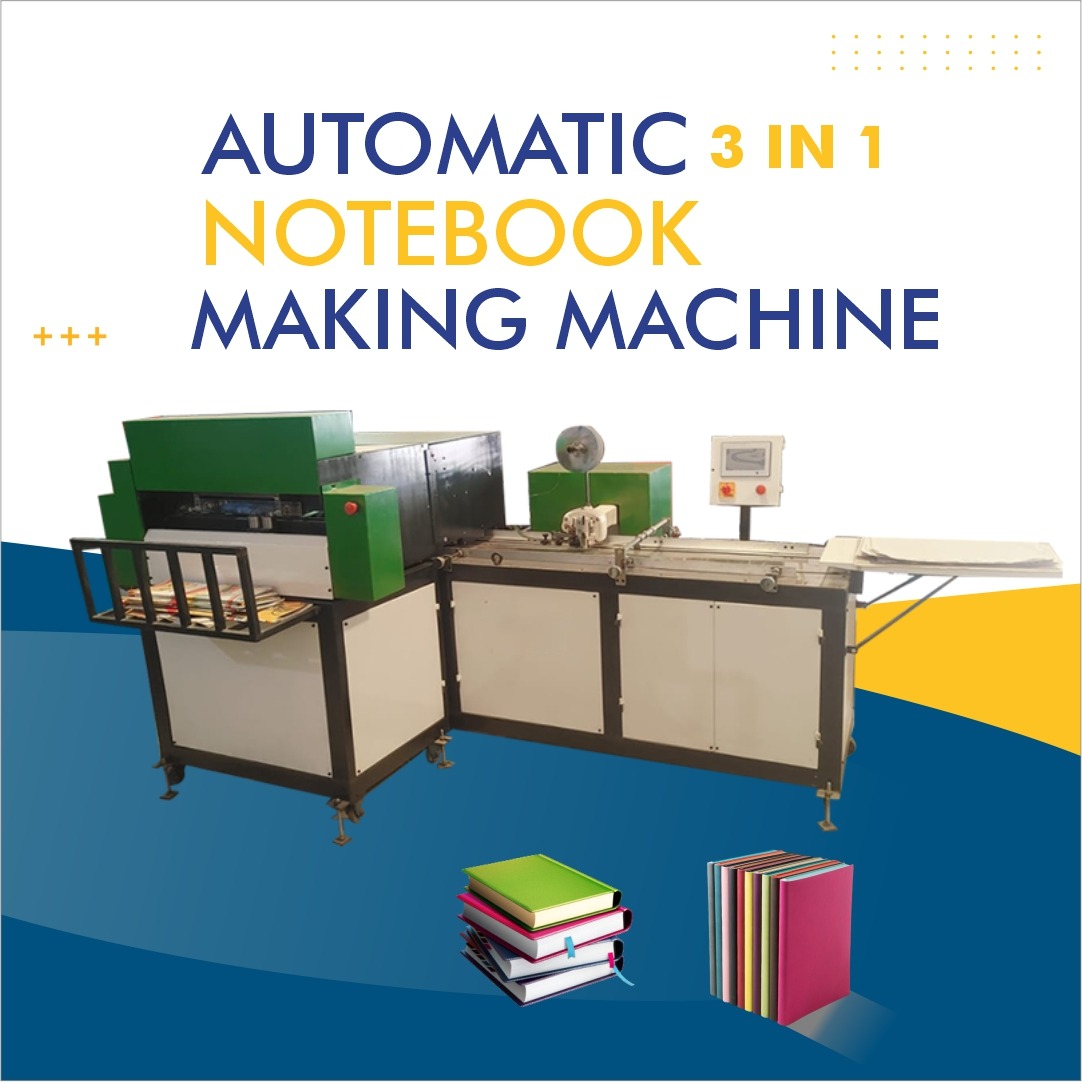

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Changlang, Arunachal Pradesh | Leading Manufacturer & Supplier

Notebook Making Machine Changlang | Arunachal Pradesh

In the scenic district of Changlang in Arunachal Pradesh, emerging demand for local stationery manufacturing has opened new horizons for small-scale industry. For entrepreneurs, schools, and printing businesses seeking to produce notebooks locally, investing in the right notebook making machine can transform operations—reducing cost, improving quality, and ensuring faster turnaround. This guide offers a comprehensive view of procuring, installing, and maintaining notebook production equipment in Changlang, Arunachal Pradesh.

Why Choose Local Notebook Making Machines in Changlang

-

Reduced Transportation Cost & Lead Time

When you source from a supplier familiar with Arunachal Pradesh and nearby regions, you save on freight charges and avoid delays that climbing terrain often incurs. Local availability means quicker installation and faster servicing. -

Customized Specifications for Local Demand

Notebook preferences (size, page count, binding style) vary in Northeast India. By choosing a local supplier or manufacturer that understands Changlang’s market demand, you can customize your school notebook machine to suit popular sizes, cover design, and binding styles. -

After-Sales Support & Maintenance

Machines require calibration and maintenance. A nearby supplier ensures ease of technical support, spare parts, and periodic servicing without long downtime. -

Promoting Local Industry & Employment

Investing in stationery production locally encourages job creation, increases access to affordable notebooks for schools, and contributes to regional development.

Types of Notebook Making Machines

Here are different categories of notebook-making and stationery-manufacturing machines you might consider:

-

Manual Notebook Making Machine

A system operated by hand or foot pedal. Ideal for very small-scale production or pilot runs. Low investment, zero electricity cost, but limited production capacity. -

Semi-automatic Notebook Maker

A hybrid machine where certain operations (cutting, folding, binding) are automated while others require manual assistance. Suitable for small business owners wanting better productivity without full automation. -

Automatic Notebook Production Machine

Fully automated systems that take raw paper reels or sheets through cutting, folding, collating, binding, and trimming. High output, consistent quality, ideal for substantial volume demand. -

Paper Binding Equipment

Equipment focused on binding and finishing – such as wire binding, spiral binding, glued binding, edge trimming. These can be used alongside existing cutting/folding infrastructure. -

Stationery Production Machine

A broader class of machinery that may combine features (paper creasing, embossing, cover printing or pre-lamination) along with notebook binding.

Each of these comes with trade-offs in initial cost, space requirement, labor, energy consumption, and maintenance.

Key Specifications to Consider

When choosing a notebook production machine, evaluate the following technical specifications to ensure it suits Changlang’s utility and business constraints:

-

Sheet size capacity (A4, A5, custom sizes)

-

Maximum notebook thickness / page count

-

Binding type (Staple/wire/stitch or glue)

-

Speed / production capacity (notebooks per hour or per shift)

-

Electric power supply (voltage, three-phase or single-phase)

-

Footprint & footprint clearance (space in your workshop)

-

Material of components (steel frame, corrosion resistance, spare part availability)

-

Operator skill level (ease of use, need for training)

-

Warranty & spare parts availability

-

Noise & safety compliance

A supplier familiar with Arunachal Pradesh regulations can also help ensure you meet any local certifications or safety norms.

Purchasing Process: How To Buy in Changlang

-

Initial Inquiry & Specification

Reach out to a notebook making machine supplier with your requirements (e.g. notebook size, batch size, binding style). Ask them for machine datasheets, product catalogue, and price quotation. -

Site Visit & Assessment

Have the supplier visit your workshop location in Changlang. They can assess your power supply, room layout, and suggest suitable models. -

Customization & Quotation

If you need custom features (e.g. simultaneous gluing & trimming, cover printing integration), request a tailored quote. Compare quotations from at least two vendors. -

Order & Logistics

Once you finalize the model (say a semi-automatic notebook maker or fully automatic binder), confirm delivery cost, installation schedule, training of operators, and payment terms. -

Installation & Testing

Supplier dispatches and installs the industrial notebook machine on-site in Changlang. They must test first production runs, calibrate settings (thickness, alignment, cover margins), and train your staff. -

Maintenance & Spare Parts Plan

Sign up for preventive maintenance and keep an inventory of critical spare parts (cutting blades, binding wires or glue components). A reliable stationery production machine provider will offer periodic visits.

Use Cases & Business Opportunities

School Notebook Production

Many schools and educational institutions in and around Changlang require notebooks for students. A local manufacturer can supply notebooks in bulk at lower cost, customize cover artwork to local language or school emblem, and deliver within short notice.

Printing Press Add-on Business

Existing printing or photocopy shops can add a notebook binding unit to expand their business line. With a paper binding equipment setup, you reduce dependency on distant suppliers and increase revenue per client.

Customized Gift or Premium Notebooks

You may offer premium notebooks (hard or soft covers, laminated covers, embossing). A semi-automatic or automatic notebook machine with optional finishing features can open a niche gift / corporate stationery segment in Arunachal Pradesh.

Local Cooperatives & Startup Ventures

Village-level cooperatives or self-help groups (SHGs) may pool resources to invest in a notebook maker and supply to schools and small shops in remote areas. This decentralizes distribution and improves access to educational materials in remote regions.

Challenges & Mitigations in Changlang

Operating stationery-manufacturing equipment in Changlang or similar remote areas involves some challenges. Here’s how to anticipate and manage them:

-

Electricity Reliability

Power outages or voltage fluctuations are common. Choose machines tolerant of voltage variation, provide backup stabilisers, and consider battery or generator backup for key operations. -

Climate & Humidity

Arunachal Pradesh has high rainfall during monsoon season. Ensure your workshop has good roofing, humidity control, and that machine components are rust-resistant. -

Transport & Infrastructure

Moving heavy machinery to Changlang may involve rugged roads. Factor in logistics cost for transporting the notebook making machine safely. Insist on machine delivery by modular/portable components. -

Skilled Workforce

Training operators to handle semi-automatic or programmable equipment may require technical instruction. Ensure the supplier includes training sessions and documentation in the local language, if needed. -

Regulatory Compliance

Ensure your business registration, industry licence (if any), pollution norms (waste paper or chemical glues), and workplace safety norms comply with state and district regulations.

Maintenance & Longevity

To ensure your notebook production machine operates smoothly over years:

-

Daily Cleaning & Lubrication

Clean paper dust, glue residue, and regularly lubricate moving joints or bearings. -

Scheduled Inspection

Every 3-6 months inspect cutting knives, alignment rails, motor mountings and binding mechanisms. -

Calibration Runs

Run test notebooks periodically (e.g. once a week) to check for misalignment, glue bleed or trimming edges. -

Spare Parts Stocking

Keep spare items like binding wire or glue, edge trimmers, cutting blades. If your supplier is local to Arunachal Pradesh, they might stock these. -

Software & Automation Updates

For semi-automatic or programmable machines, check firmware updates or control-panel upgrades. Ensure your operator is comfortable with adjustments.

Cost Estimation & Return on Investment

Here is a rough estimate of costs and payback period for a typical semi-automatic notebook maker installed in Changlang:

| Item | Estimated Cost (INR) | Notes |

|---|---|---|

| Machine Purchase | ₹ 3-5 lakh (depending on model & features) | Semi-automatic or small automatic binder |

| Shipping & Installation | ₹ 50,000 – ₹ 1,00,000 | Varies with road-access & distance |

| Training & Commissioning | ₹ 10,000 – ₹ 20,000 | Operator training onsite |

| Annual Maintenance | ~ 5 % of machine cost | Annual visits, parts replacement |

| Output Capacity | 500–1000 notebooks/day | Depending on machine speed |

| Selling Price per Notebook | ₹ 20–30 per piece (school-grade or custom cover) | Variation depends on cover quality & batch size |

| Monthly Revenue Estimate | ₹ 3–9 lakh | With consistent production & sales |

| Break-Even Period | 6–12 months | Based on fixed & variable costs and demand |

This simple model shows that a properly utilized automatic notebook production machine can pay back its investment within a year provided you maintain good utilization and steady orders.

How to Get Started in Changlang

-

Conduct a feasibility survey in your local town: identify schools, bookshops and gift shops that may buy your notebooks.

-

Prepare a rough business plan: machine cost, raw paper procurement, packaging & delivery cost to nearby markets.

-

Contact one or two reputable suppliers of stationery production machines in India. Request quotations for delivery up to Changlang.

-

Visit the supplier’s installed site (if possible) to see sample output, verify quality of binding, trimming & finishing.

-

Finalise purchase, get local approvals (shop license, GST registration) and begin small-scale production.

-

Market your notebooks by direct tie-ups with schools and stationery shops in Arunachal Pradesh, highlighting “locally made” and “fast delivery to Changlang & nearby areas”.

Conclusion

Setting up a notebook-making production unit in Changlang, Arunachal Pradesh has strong potential. With correct selection of a notebook making machine, informed maintenance practices, and understanding local market needs, you can build a sustainable and profitable stationery enterprise. Whether you choose a manual system for pilot runs, a semi-automatic notebook maker for steady growth, or a fully automatic binder for mass output, the right investment can hallmark quality, consistency, and local empowerment.