Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

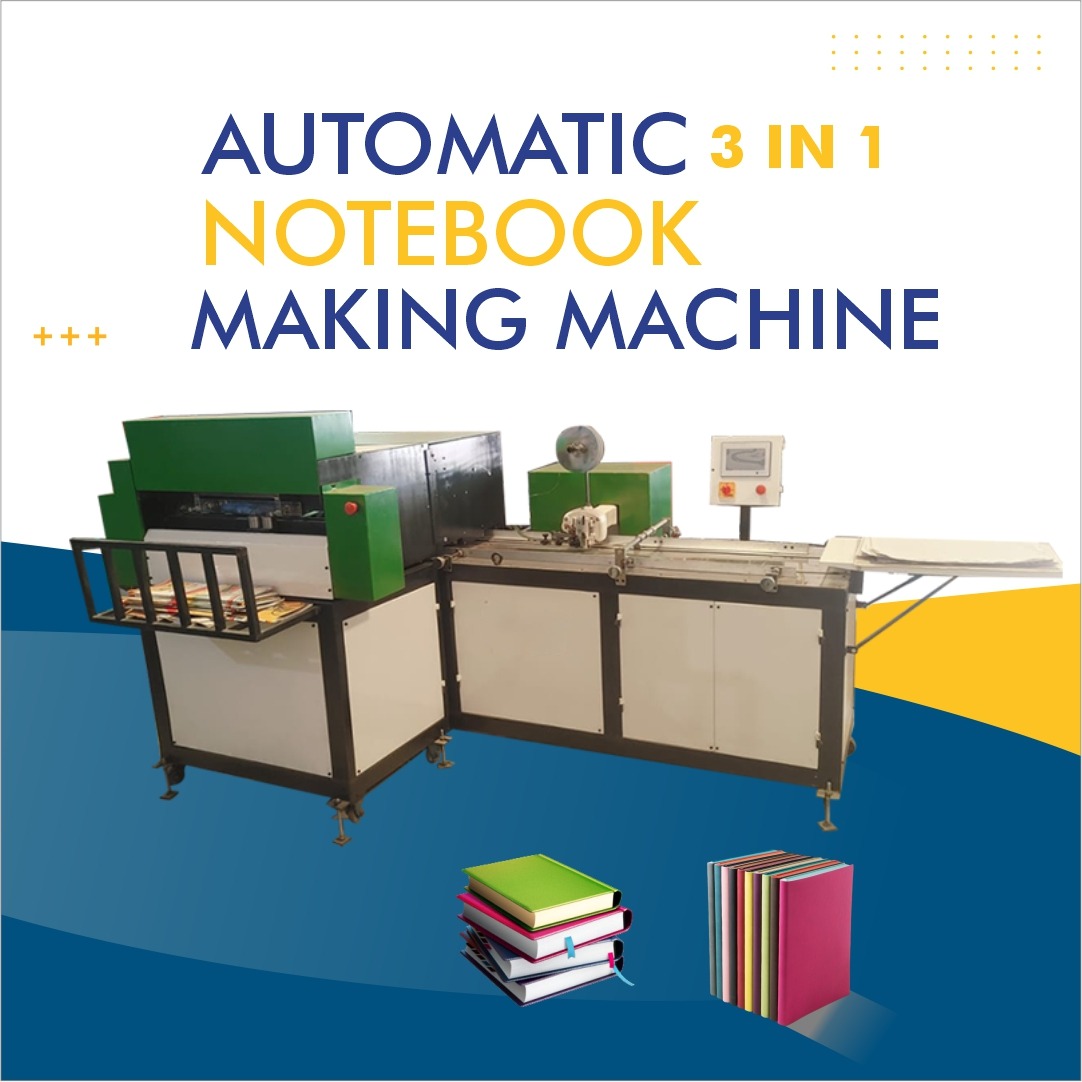

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Chaglagam – Best Suppliers & Service | Arunachal Pradesh

Notebook Making in Chaglagam | Arunachal Pradesh

Chaglagam is a remote area of Arunachal Pradesh, but demand for stationery products like notebooks and exercise books is rising steadily. Local schools, government offices, and small businesses increasingly require locally produced educational stationery to reduce dependency on distant suppliers and cut transport costs. Investing in a notebook making machine in Chaglagam offers an ideal opportunity for entrepreneurs and cooperatives to set up a sustainable notebook manufacturing unit close to end-users in the region.

A properly selected notebook production equipment can enable you to produce standard ruled notebooks, exercise books, spiral-bound pads, and other paper stationery items. In the terrain and logistical setting of Chaglagam, installing a reliable and robust industrial notebook maker or light-duty notebook machine helps reduce lead-times, lowers transport costs, and fosters local employment.

This guide covers everything you need to know about buying, installing, running, and maintaining a notebook making machine in Chaglagam, Arunachal Pradesh. It also explores the benefits, technical specifications, local approvals, and business case for notebook production equipment in remote Himalayan-foothill regions.

2. Why Choose Local Notebook Manufacturing?

-

Reduced logistics cost: Transporting finished notebooks from distant cities to Chaglagam is expensive and slow. Local production lowers delivery delays and freight charges.

-

Customisation & Quality Control: A local book binding machine built into your unit allows you to control paper quality, ruling styles, and cover design for regional needs.

-

Job creation: Setting up a notebook manufacturing unit generates employment for youth in Chaglagam, encouraging skills development in mechanical operation and stationery business.

-

Faster Turnaround: Local production means faster order fulfillment for schools, NGOs, and government bodies operating in remote parts of Arunachal Pradesh.

-

Sustainability: Producing stationery locally helps reduce carbon footprint by lowering transport mileage across hilly roads.

3. Types of Notebook Making Machines for Chaglagam

Different variants suit different production scales, floor space, and electricity supply constraints in remote areas. Below are common types:

| Type | Description |

|---|---|

| Manual or Semi-Automatic Notebook Machine | Useful for small-scale production. Requires some manual intervention, lower cost, easier maintenance. |

| Fully Automatic Notebook Production Equipment | Higher throughput machines with cutting, ruling, binding, stapling, trimming integrated. Ideal for larger orders or cooperative-level production. |

| Spiral / Wire-O Binding Notebook Machine | If you plan to produce notebooks with spiral binding or wire binding instead of stitched binding. |

| Soft-Cover or Hard-Cover Binding Machine | For premium notebooks with decorative covers or laminated boards. |

| Binding-only / Trimming-only Modules | As add-on or upgradeable modules to expand your existing production line. |

You should evaluate power supply availability in Chaglagam (voltage fluctuations, generator-backups) and floor-space constraints before selecting a model.

Technical factors to check include:

-

Sheet-cutting precision

-

Ruling head accuracy

-

Binding strength (staple / stitch / glue / spiral)

-

Production capacity (notebooks per hour or per day)

-

Power consumption (kW)

-

Spare-part availability

-

Ease of local servicing

4. Setting Up Notebook Production in Chaglagam

a) Location and Premises

Choose a site with stable floor base, sheltered from monsoon rains and snow during winters. Ensure protection against humidity. Make sure your workshop has adequate roof height, drainage, and access to road for bringing raw materials (paper, board, staples, etc.) and dispatching finished notebooks.

b) Power & Utilities

Reliability of electricity supply in remote Arunachal Pradesh can be variable. You might need to install stabilisers, backup inverters or diesel generator to safeguard your industrial notebook maker equipment. Ensure voltage stability and earthing compliance.

c) Raw Material Sourcing

Paper sheets, ruled templates, cover boards, staples or binding wire must be procured. You may need to coordinate with suppliers from closer markets (Itanagar, Assam border) or transport in bulk to reduce per-unit cost.

d) Workforce Skills & Training

Operating a notebook making machine demands basic mechanical understanding, routine maintenance, fault diagnosis, and quality inspection. You may hire trained personnel or arrange training for locals. Manufacturer’s support can help with commissioning and routine servicing.

e) Permits & Legal Compliance

Registering a small manufacturing unit in Arunachal Pradesh may require local government approvals, trade license, environment-compliance certificate (if any), and adherence to electrical safety codes. Make sure you liaise with district / tehsil authorities for compliance.

5. Cost Breakdown & Business Viability

| Item | Approximate Cost / Consideration |

|---|---|

| Machine purchase (manual / semi-automatic model) | INR X lakh to Y lakh depending on brand and capacity |

| Installation & Shipping to Chaglagam | Transport from closest road-accessible depot plus labour charges |

| Power backup equipment (inverter / stabiliser / generator) | INR Z thousand/runs |

| Raw-material inventory (paper, binding supplies) | Bulk procurement cost per batch |

| Routine Maintenance & spare parts | Annual maintenance contract or parts reserve budget |

| Production Volume & Pricing | Estimate number of notebooks per month, unit cost vs selling price to schools / businesses |

You should build a basic break-even analysis:

-

Estimate how many notebooks must be sold per month to cover fixed cost (machine amortisation + utilities + maintenance).

-

Compare that with local demand from schools, offices, retail shops in and around Chaglagam.

-

Factor seasonal demand (e.g. start of academic year) to manage inventory and cash-flow cycle.

6. Supplier & Service Options

Because Chaglagam is remote, you should select a supplier who:

-

Delivers to Arunachal Pradesh or arranges transport

-

Provides on-site installation support or detailed remote guidance

-

Supplies spare parts locally or via Assam / Itanagar logistics corridors

-

Offers technical training or user manual in accessible format

You may contact machinery vendors in nearby regions like Assam or industrial machinery suppliers in Itanagar or Guwahati. Ask for demonstrator videos or testimonials of previous installations in hilly terrain.

Request quotations for models that suit your intended daily output. Ensure after-sales service contract and warranty coverage extend to remote delivery locations.

7. Operating & Maintenance Best Practices

To run a notebook production unit effectively in Chaglagam:

-

Keep a regular preventive maintenance schedule: cleaning cutters, checking blade sharpness, lubricating moving parts.

-

Monitor temperature and humidity in the workshop to avoid paper deformation or curling.

-

Maintain a log-book of downtime, faults, and repairs to identify frequent failure modes.

-

Stock common spare items (blades, stapler heads, rulers, motors) to minimise downtime while parts ship in.

-

Train multiple staff members on the machine operator panel, so production does not halt when one person is unavailable.

Also consider periodic calibration of cutting / ruling / trimming heads to maintain consistent notebook sizing and appearance.

8. Marketing & Selling Your Notebooks

Once your machine is up and running, you should market your locally-produced notebooks to:

-

Schools (primary / secondary), colleges and coaching centres in Arunachal Pradesh

-

Local government offices requesting stationery

-

Retail stationery shops in Chaglagam, surrounding villages and small towns

-

Community organisations, NGOs, and local self-help groups

Promote your USP as locally-manufactured stationery — faster delivery, custom ruling styles, and lower cost. You may brand your notebooks with local motifs or tribal designs to create regional appeal.

Consider offering bulk-order discounts at the start of the school year and engaging with district education-offices for supply contracts.

9. Challenges & Risk Mitigation

Operating a production unit in Chaglagam faces certain challenges:

-

Logistics delays especially during monsoon season or road blockages. Mitigation: keep buffer inventory, schedule deliveries proactively.

-

Power outages or voltage fluctuation — invest in proper backup and stabilisation equipment.

-

Skilled labour turnover — maintain documented SOPs, cross-train team members.

-

Raw-material quality variance — maintain close quality checks at receipt, negotiate with suppliers for consistent paper stock.

Mitigate by building contingency protocols and financial reserves for delays or damage.

Conclusion

Setting up a notebook making machine in Chaglagam, Arunachal Pradesh can be a viable micro-industrial enterprise. By choosing the right notebook production equipment, accounting for logistics, power backup, workforce training, and quality control, you can establish a sustainable stationery manufacturing business serving local demand.