Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

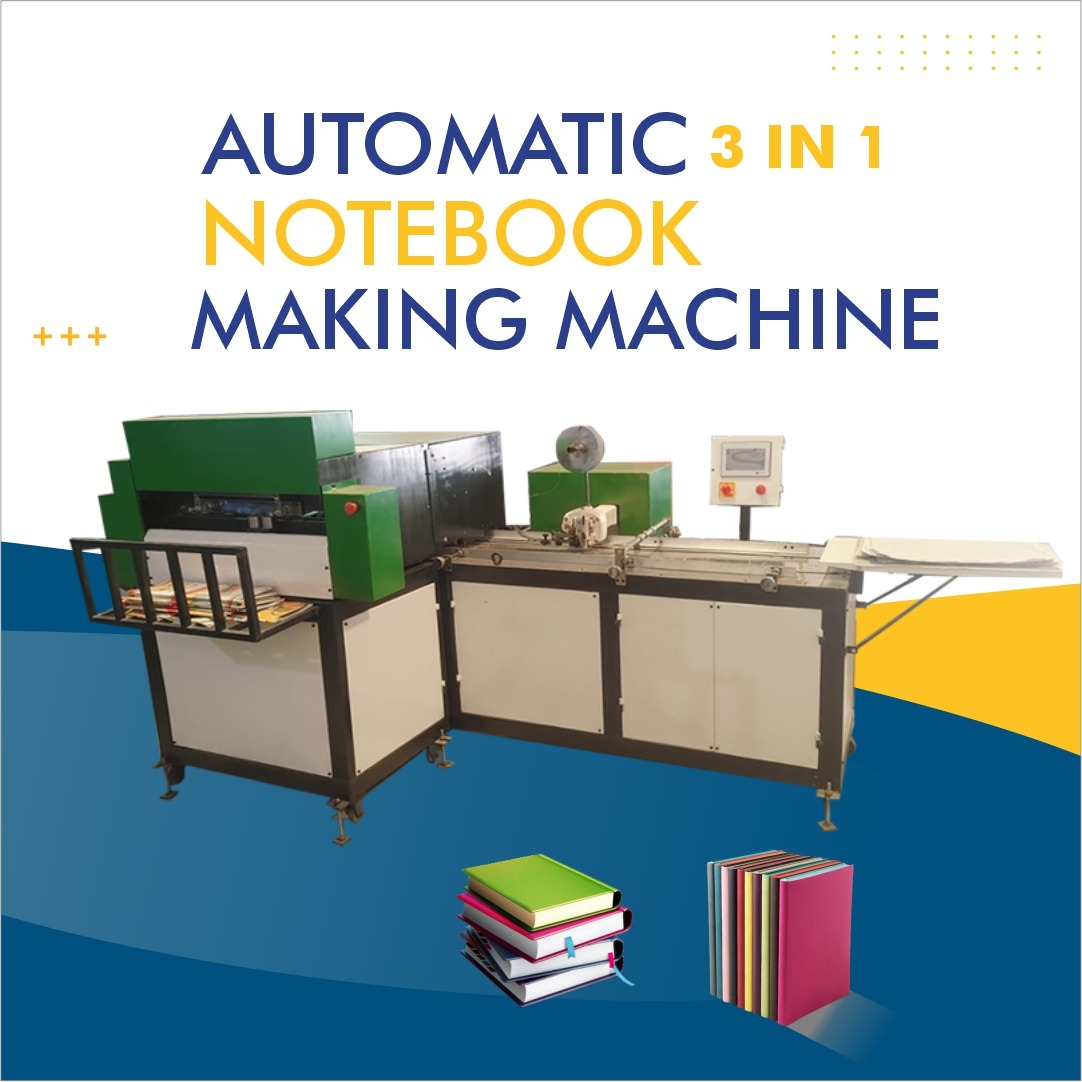

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Bomdila Arunachal Pradesh | Buy Notebook Manufacturing Machine

Notebook Making Machine Bomdila | Arunachal Pradesh

If you're looking to start or expand a notebook manufacturing business in Arunachal Pradesh, a reliable notebook making machine is the backbone of your operation. Located in Bomdila, we supply top-tier stationery production equipment that helps entrepreneurs produce high-quality notebooks, registers, diaries and exercise books. This content explores features, benefits, business viability, and considerations for setting up a notebook making machine in Bomdila, Arunachal Pradesh.

You will find details on machine types, production capacity, setup requirements, raw materials, cost considerations, and how your location in Bomdila can offer you strategic advantages in Northeast India.

Why Choose Bomdila, Arunachal Pradesh

Bomdila is a town in West Kameng district in Arunachal Pradesh. Although remote, setting up manufacturing here can offer advantages:

-

Proximity to local schools, educational institutions and government offices which demand stationery regularly.

-

Possibility of favourable local incentives, lower land cost compared to metro areas.

-

Opportunity to serve untapped markets in mountainous regions and tribal areas.

-

Lower competition in localised stationery production means you can build brand recognition and service responsiveness.

However, you should also consider challenges such as logistics (transport of raw paper into Arunachal, distribution of final notebooks out of Bomdila), power infrastructure, local skilled labour availability, and regulatory compliance.

Types of Notebook Making Machines

Selecting the right type of the notebook making machine is crucial. Here are common variants:

-

Manual / Semi-automatic Notebook Making Machine

-

Requires operator intervention for feeding, folding, stitching or cutting.

-

Ideal for small-scale production or startup phase.

-

Lower capital cost.

-

Example: Semi-Automatic Notebook Making Machine from Bhartiya Machine Works. bhartiyamachineworks.com

-

-

Fully Automatic Notebook Making Machine

-

Automates multiple processes: cutting, stitching, folding, edge-squaring, packing.

-

Faster production, consistent quality, less human error.

-

Higher investment but better throughput.

-

Examples include machines by Sujata Machines with stitching / folding / edge squaring capabilities. sujatamachines.in+1

-

-

Compact / Single-Head Automatic Models

-

Suitable if you want partial automation in a smaller footprint.

-

May stitch, fold and square edges in a combined line. endurancemachinery.com

-

You may combine these in a full notebook manufacturing plant: cutting machine, stitching head, folding station, edge-squaring, and packaging / packing.

Key Features to Evaluate

When choosing a notebook making machine, consider:

-

Production capacity (notebooks per hour or per day)

-

Automation grade (manual / semi-automatic / fully automatic)

-

Supported sizes (A4, custom sizes, thickness / pages per notebook)

-

Power requirement (single-phase or three-phase, voltage)

-

Build quality and materials (steel frame, durable components)

-

After-sales support & warranty

-

Price & return on investment

-

Flexibility (to adapt various notebook formats: ruled / unruled pages, cover types)

For instance, Sujata’s automatic notebook making machines have features like folding, stitching and edge squaring in one integrated line. sujatamachines.in

Another example: Kesya International’s notebook making machine offers capacity from 1,000 to 3,000 notebooks per hour with adjustable sizes. kesyainternational.com

Cost Estimate & Business Viability

-

Entry-level semi-automatic machines may cost a few lakhs of rupees; fully automated units may cost significantly more depending on capacity and brand.

-

Raw material cost (paper, cover board, binding wire or staples) is a major recurring cost.

-

Labour cost: operating staff, machine operator(s), finishing and packing process.

-

Utilities: electricity — ensure steady power supply in Bomdila or invest in backup.

-

Transportation & logistics: bringing raw paper into Bomdila and distributing finished notebooks to schools, retail outlets across Arunachal Pradesh or neighbouring states.

-

Pricing your notebooks to cover costs and deliver margin: you must factor competition (imported notebooks, big brands) and local affordability.

You should prepare a financial projection: capital outlay (machine + installation + premises setup), operating cost (materials + labour + utilities + maintenance), sales volume (units/month), revenue per notebook, break-even point.

Setup Considerations in Bomdila

-

Location & Premises

-

Secure a suitable workshop or factory space with enough floor area, access for loading / unloading.

-

Ensure compliance with local building regulations, fire safety and environmental norms.

-

-

Permissions & Licences

-

Business registration / MSME registration in Arunachal Pradesh.

-

GST registration.

-

Any local permissions for manufacturing unit (pollution control / waste disposal if applicable).

-

-

Power & Utilities

-

Confirm availability of reliable electricity supply in Bomdila.

-

Consider backup generator or inverter system if power outages are frequent.

-

Proper drainage, lighting and worker amenities.

-

-

Labour & Skill

-

Hire and train operators to run the notebook making machine, handle maintenance, quality control.

-

Potentially source local workers from Bomdila / neighbouring areas.

-

-

Raw Material Sourcing

-

Paper sheets (inner pages), cover paper or board, binding wire or staples, packaging supply.

-

Source from suppliers in neighbouring states (Assam, other parts of Northeast) or from PAN-India vendors. Factor inbound freight cost to Bomdila.

-

-

Quality Control & Customization

-

Offer custom notebook formats (ruled / plain pages, different sizes, thickness).

-

Ensure consistent stitching, proper trimming, clean edges (edge-squaring), and attractive covers.

-

-

Marketing & Sales Channels

-

Local schools, colleges, coaching centres in Arunachal Pradesh.

-

Government tenders for stationery supply.

-

Retail stores, online or local wholesale distribution.

-

Emphasize “Made in Arunachal” advantage, local availability, faster delivery, customized orders.

-

Advantages & Challenges

Advantages

-

Reduced lead time for local supply; lower freight costs for distributing within Arunachal Pradesh.

-

Ability to offer customization quickly for local institutions.

-

Establish first-mover or niche printing / stationery manufacturer in remotish region.

-

Possible incentives or subsidies under Northeast India economic development schemes.

Challenges

-

Higher cost of transporting raw materials into hilly terrain.

-

Maintenance & spare part availability may be slower than metro locations.

-

Demand fluctuation: local demand may be smaller in volume compared to big cities.

-

Seasonality, especially in school supply cycles (academic year).

How to Choose Your Machine Supplier & Installation Partner

When sourcing a notebook making machine for Bomdila:

-

Ask suppliers about installation support, on-site commissioning, and training for staff.

-

Inquire about after-sales service and availability of spare parts near your region (or how quickly parts can be delivered).

-

Visit or ask for demo videos or existing customer references.

-

Verify machine certification, safety standards, and electrical compatibility.

-

Compare multiple vendors for cost vs. quality vs. uptime. Consider both Indian manufacturers (e.g. Bhartiya Machine Works bhartiyamachineworks.com or Sujata / Endurance / Kesya etc. sujatamachines.in+2kesyainternational.com+2 ).

Example Business Scenario

Suppose you plan to buy a semi-automatic notebook making machine and operate it in Bomdila with a capacity of 1,000 notebooks/day.

-

Initial investment: machine cost + setup + space rent

-

Operating cost: paper, binding wire, labour for operators & finishing staff

-

Pricing strategy: supply to local schools/coaching centres at a margin over production cost

-

Scale up: you may gradually upgrade to more automated model to increase throughput and reduce per-unit cost.

-

Eventually, you could diversify into custom diaries, planners or registers for nearby districts or neighbouring states.

With careful planning, you can build a profitable stationery manufacturing unit in Bomdila using a notebook making machine as the production core.

Conclusion

A notebook making machine located in Bomdila, Arunachal Pradesh can be a strategic investment for stationery manufacturing in the region. Choosing between semi-automatic or fully automatic models depends on your scale, budget, and target market. While there are logistical and infrastructure challenges, the benefits of local production, customization, reduced lead times, and untapped market potential are significant.