Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

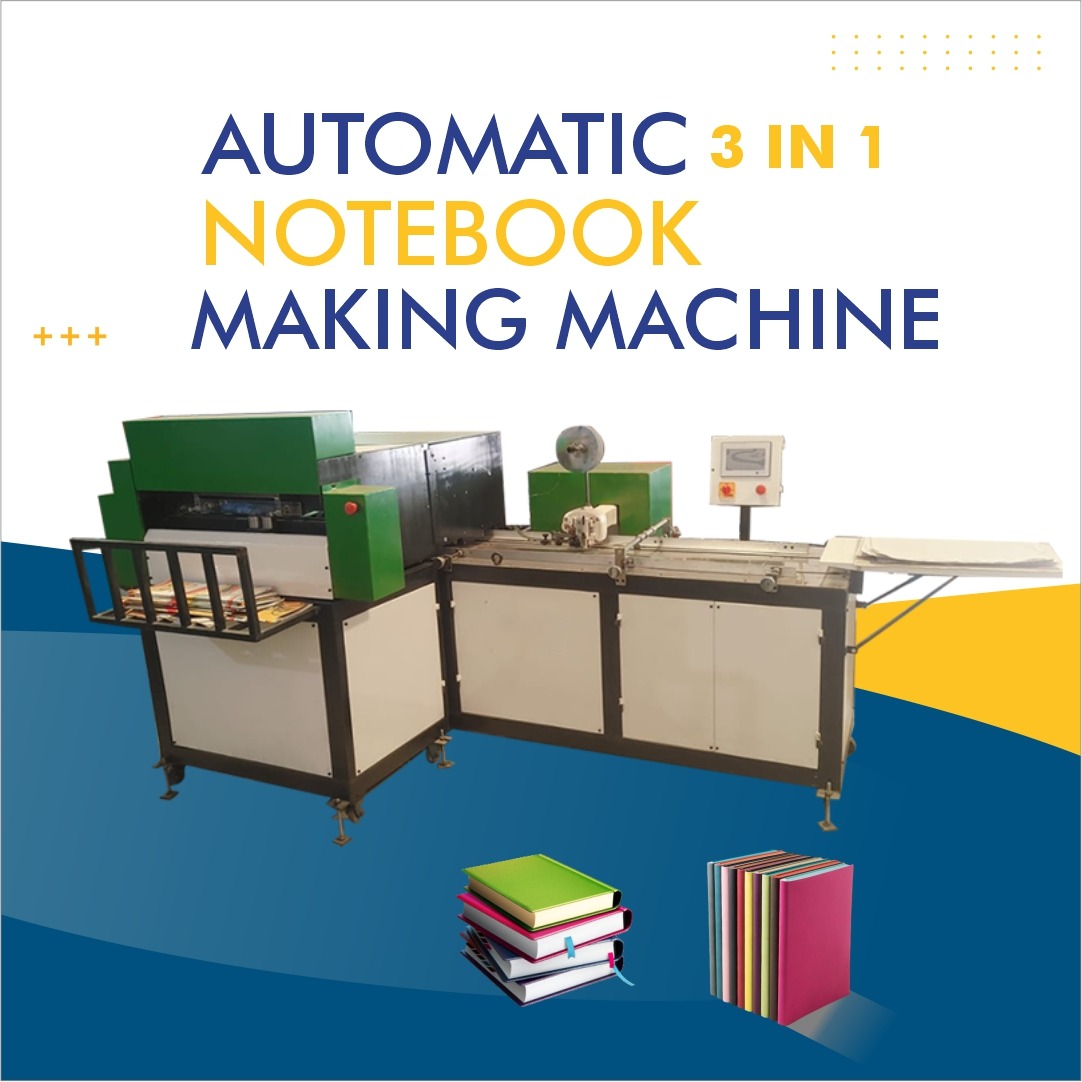

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machines in Boleng, Arunachal Pradesh | Reliable & Efficient

Notebook Making Machine in Boleng | Arunachal Pradesh

Notebook production is a vital segment within the educational stationery industry. In Boleng, Arunachal Pradesh, where access to quality school supplies can directly impact learning outcomes, investing in a high-performance notebook making machine can revolutionize local manufacturing. This article explores everything you need to know — from technology options and benefits to installation procedure and operational tips — to help you choose the right notebook making machine in Boleng, Arunachal Pradesh.

We will cover the technical specifications, cost considerations, applications, and maintenance guidelines. The primary goal is to enable entrepreneurs, small manufacturers, and educational institutions to assess and deploy a notebook making machine that suits their production needs.

Why Boleng, Arunachal Pradesh is an Emerging Hub for Stationery Production

-

Strategic Location: Boleng is situated in Siang district of Arunachal Pradesh, offering access to raw materials such as local paper mills and proximity to rural schools and educational centers.

-

Growing Demand: As regional educational initiatives expand under government and NGO efforts, the demand for locally produced notebooks and stationery is rising.

-

Cost Advantage: Local manufacturing in Boleng reduces logistics costs associated with transporting notebooks from distant suppliers and supports local employment in the stationery production sector.

-

Supportive Policy Landscape: Arunachal Pradesh administration supports small-scale industrial development, offering incentives for entrepreneurs investing in manufacturing infrastructure such as paper binding machines and assembly tools.

Because of these factors, establishing a facility in Boleng with a suitable notebook making machine can yield strong returns and social impact.

Understanding the Notebook Making Machine

A notebook making machine is a composite piece of production equipment that performs tasks such as cutting paper sheets, folding, edge binding, punching holes, cover lamination, and trimming edges. Depending on complexity, it can include semi-automatic or fully automatic modules.

Key Components & Functionalities

-

Sheet feeder & cutter

Accurately cuts large paper sheets into foldable pages.

Ensures consistent quality across notebooks. -

Collating & folding section

Aligns pages in sequence and folds them; critical for booklet or notebook format. -

Binding mechanism

A binding unit—could be glue binding, spiral binding, or thread stitching. In many local setups, paper binding machines use hot-melt glue or saddle stitching. -

Cover lamination & trimming

Attaches and trims covers to size; gives durability and finish. -

Punching or perforation

For ring binding or pins, enabling notebooks to be inserted into binders if required. -

Trimming edges & final finishing

Removes uneven edges for neat appearance. -

Control panel & automation interface

Permits speed control, batch adjustment, and safety interlocks.

When all these subsystems work in harmony, you have an efficient mechanical binding system that ensures high-quality output with low manual intervention.

Types of Notebook Making Machines

-

Semi-automatic notebook making machine – Requires manual loading at different stages; lower cost; suitable for small scale school supplies manufacture.

-

Fully automatic notebook making machine – Automates everything from feeding to trimming; suitable for medium-to-large production volumes.

-

Custom modular systems – Configurable modules shipped separately; allows staged investment and upgrades.

Choosing the Right Equipment for Boleng

When setting up in Boleng, these considerations are critical:

-

Production Capacity

Estimate monthly or daily output of notebooks. For example, target 2,000 notebooks per day or 60,000 per month. Match machine capacity accordingly. -

Electricity & Power Infrastructure

Check local grid reliability, voltage stability, and backup power needs. Machines with automation may require stable three-phase supply. -

Raw Material Availability

Source valid paper stock, cardboard for covers, glue supply, binding wire (if using spiral or wire binding). Proximity to suppliers influences cost. -

Skill & Labor

Operators must be trained on machine operation and maintenance. Local labor in Boleng may need training on automated binding techniques and safety protocols. -

Space & Layout

Allocate adequate floor area for the machine footprint, paper storage, finished goods, and workflow paths. Ensure ventilation and compliance with building permissions. -

Budget & Financing

Total cost includes machine price, shipping to Boleng, installation, training, and spare parts. Government subsidies or small-scale industry grants may be available in Arunachal Pradesh. -

After-sales Support

Choose vendors offering remote or onsite maintenance support; spare parts availability; and documentation in local languages if needed.

Operational Workflow for Notebook Production

Here’s a sample workflow in a stationery production setting in Boleng, using a notebook making machine:

-

Raw Material Receiving

Paper rolls or sheets arrive and stored in a dry environment. Moisture control is essential to prevent jamming. -

Cutting & Folding

Feed raw paper into the sheet feeder; machine cuts and folds into signature sets. -

Binding

Collated signatures undergo binding through glue or stitching. The paper binding machine section activates and binds pages to the cover. -

Cover lamination & trimming

Cover sheets inserted; laminated or glued; excess edges trimmed for final finish. -

Quality Inspection

Inspect each batch for alignment, edge finish, binding strength, and page count. Reject faulty units and re-adjust machine calibration. -

Packaging & Dispatch

Pack finished notebooks and label them. If supplying to nearby schools in Boleng or neighbouring towns, arrange local delivery logistics. -

Maintenance Schedule

Daily cleaning, weekly lubrication, monthly calibration inspection to ensure consistent performance.

Benefits of Owning a Notebook Making Machine in Boleng

-

Local production reduces delivery delays and dependency on external suppliers. This improves supply chain resilience for schools and NGOs in the region.

-

Cost savings on transport and middle-men margins, improving profit margins for local entrepreneurs or cooperatives.

-

Customization abilities – size, cover design, binding style can be modified locally to suit customer preferences such as local language (Miing, Adi, etc.) branding.

-

Scalability – Starting with a small-capacity machine enables gradual scaling into full-fledged stationery production units.

-

Employment generation – Hiring local workforce for operation, maintenance, and quality control contributes to economic upliftment in Boleng and the surrounding villages.

Case Study (Scenario in Boleng)

Imagine a cooperative in Boleng sets up a modest notebook making machine unit with capacity to produce 50,000 A4-ruled notebooks per year. They supply local schools and government programs.

-

Initial investment: procurement of a semi-automatic binding line (includes mechanical binding system, cutter, trimmer, and finishing modules).

-

Monthly operational cost: raw paper, glue, electricity, labor.

-

Revenue: selling at ₹15 per notebook yields ₹750,000 annual revenue.

-

Profit margins improved by using local materials and reducing transport overhead.

-

Over two years, the setup breaks even and begins to yield surplus income that can be reinvested into expanding production to other districts in Arunachal Pradesh.

This demonstrates how an automated binding or paper binding machine investment can provide social and economic returns.

Maintenance & Sustainability Best Practices

-

Preventive Maintenance

Schedule cleaning and lubrication. Replace worn blades and rollers. This keeps the mechanical binding system reliable. -

Training & Safety

Conduct operator training sessions. Implement lockdown or safety covers on cutting/jamming zones. -

Energy Efficiency

Consider power-saving modes on automation gear. Use LED lighting, proper insulation, and backup generation if grid is unstable in Boleng. -

Environmental Considerations

Use eco-friendly glue or recycled paper where possible. Minimize scrap through precise calibration. Acceptable disposal of off-cuts and waste paper. -

Quality Documentation

Maintain logs of machine settings for each notebook type. This helps in replication and consistent output quality, an advantage for education materials production.

How to Source Notebook Making Machines

If you’re looking to procure a notebook making machine for Boleng, Arunachal Pradesh:

-

Contact manufacturers who provide shipping, installation, and training to remote locations.

-

Request a demo and video of automated binding in action.

-

Ask for references from other customers in similar locations (hilly or remote terrain).

-

Verify warranty terms, spare-parts supply time, and remote support options.

-

Ensure compliance with regional electrical safety and import-clearance procedures.

By evaluating vendors on these criteria, you can minimize downtime and maximize return on investment for your school supplies manufacture operation.

Future Outlook & Expansion Potential

With increased literacy missions, social sector partnerships, and community-driven enterprises in Arunachal Pradesh, the demand for locally produced notebooks and stationery is poised for growth. Upgrading from a semi-automatic to a fully automated notebook making machine can help scale production capacity to meet regional contracts.

Once established in Boleng, your facility could expand into adjacent districts, diversifying into exercise books, diaries, or promotional notebooks. This diversification leverages the same stationery production infrastructure with minor modifications.

Conclusion

Installing a specialized notebook making machine in Boleng, Arunachal Pradesh offers a promising opportunity for entrepreneurs, cooperatives, and educational initiatives to produce high-quality notebooks locally. By carefully selecting the right machine—including its capacity, automation level, maintenance support, and integration into local logistics—you stand to gain economic benefits while supporting education in the region.