Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

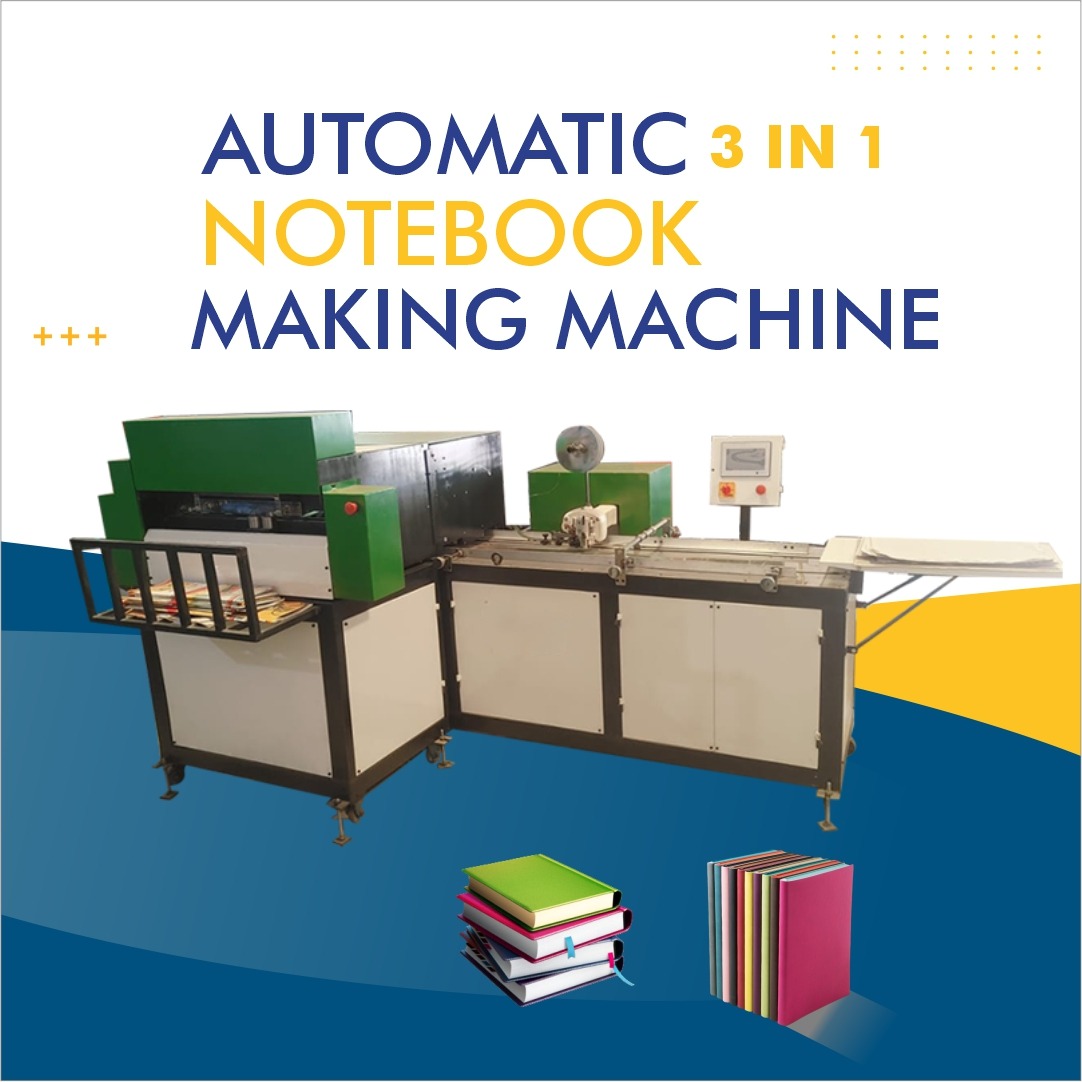

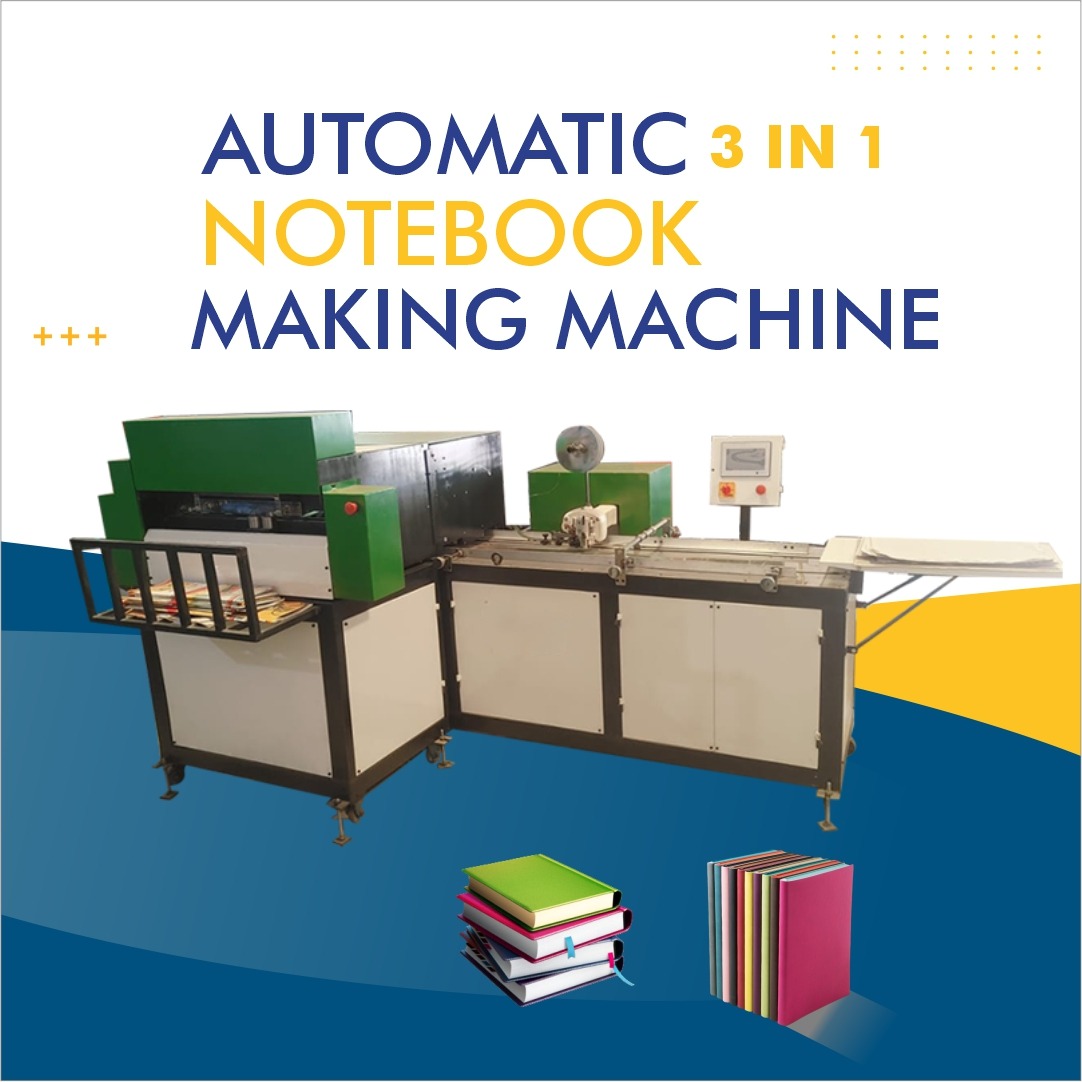

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Buy Notebook Making Machine in Balukpong | High Quality Equipment in Arunachal Pradesh

Notebook Making Machine in Balukpong | Arunachal Pradesh

In the serene environs of Balukpong, Arunachal Pradesh, the demand for reliable and efficient notebook making machines is rising steadily. Educational institutions, small-scale manufacturers, and local entrepreneurs are seeking notebook making equipment to set up in-house production facilities. This guide offers a comprehensive overview of notebook making machine choices, benefits, and implementation strategies tailored to Balukpong and the broader region.

This content is optimized for SEO and provides in-depth information about the features, selection criteria, installation, local services, and cost considerations of notebook making machines, while repeating key synonyms strategically to enhance searchability.

1. What is a Notebook Making Machine?

A notebook making machine refers to specialized equipment used to convert paper sheets into finished notebooks. These machines may include cutting, folding, gathering, stitching or binding, trimming, embossing, and cover lamination. They automate many manual steps, enabling consistent quality, higher output, and reduced labor cost.

Depending on configuration, you may find machines labeled as notebook production machines, paper binding equipment, or bookbinding machines. Although the underlying operations overlap, each variant can be configured for different binding methods: stitching, spiral binding, glue binding or hard/soft covers.

Such machines are used by educational publishers, corporate gifting units, print-shops, and school-level production units.

2. Why Set Up in Balukpong, Arunachal Pradesh?

Strategic Location & Opportunity:

-

Balukpong is located in East Kameng district, near the Assam-Arunachal border, providing logistical access to both states.

-

Demand for notebooks remains high because of growing student population, new schools, and government educational programs.

-

Local production by entrepreneurs can reduce dependency on imports or shipments from distant manufacturers.

Cost and Incentives:

-

Proximity to raw material supplies such as paper rolls from Assam or other nearby suppliers can reduce transport costs.

-

Potential access to state-level subsidies, industrial incentives, or infrastructure grants for small-scale manufacturing or MSMEs in Arunachal Pradesh.

Market Demand:

-

Government orders for textbooks or notebooks for schools under state and central schemes.

-

Customized notebooks for institutions and training centres.

-

Export potential to bordering districts of Assam and neighbouring states.

3. Types of Notebook Making Machines

When selecting a machine for Balukpong operations, consider the following categories:

-

Manual or Semi-Automatic Notebook Making Machine

Lower-cost option for new startups. Performs basic folding, stapling or calling for manual intervention in certain stages. -

Fully Automatic Notebook Production Machine

More expensive, higher throughput, minimal manual labor. Can include automatic feeding, cutting, stitching, trimming. -

Spiral / Wire-O Binding Notebook Equipment

Designed for spiral-bound notebooks. Ideal for academic pads, diaries or planners. -

Softcover Glue-Binding Notebook Equipment

Suitable for paperback covers or soft bound notebooks. Requires glue-application systems and cover trimming. -

Hybrid Notebook Manufacturing Equipment

Combines features such as stitching plus trimming or embossing. Useful for professional finishing.

Each machine type has trade-offs in terms of speed (notebooks per hour), output quality, cost, maintenance, and ease of operation.

4. Key Specifications to Consider

When evaluating a notebook production machine for installation in Balukpong, focus on:

-

Capacity / Output Rate: How many notebooks per hour or per shift. Higher capacity machines reduce per-unit cost, but require stable electricity and space.

-

Paper Size Compatibility: A4, A5, custom sizes used by local schools.

-

Binding Method: Stapling, stitching, glue binding, spiral/wire binding.

-

Automation Level: Manual set-up vs automatic feeding, cutting, trimming.

-

Power Supply & Energy Efficiency: Considering local grid stability, voltage fluctuations, and energy cost in Arunachal Pradesh.

-

Footprint & Footprint Requirements: Floor area, building height, access for loading/unloading raw paper and storing finished notebooks.

-

Raw Material Handling: Stock of paper sheets, cover boards, binding wire or thread. Local availability or need to transport supplies.

-

After-Sales Support & Training: Importance of reliable technical service, spare parts supply, and operator training in remote regions.

In addition, consider compliance with safety standards and durability, particularly in a high-humidity or monsoon-affected region.

5. Benefits of Installing Notebook Making Equipment

-

Cost Control & Quality Consistency

Producing notebooks locally lets you control raw material quality, reduce defects, and maintain uniform standards rather than relying on external vendors. -

Faster Delivery and Responsiveness

You can fulfill urgent requirements for schools, training centres, local events, or institutional orders quickly without shipping delays. -

Customization & Branding

Local notebooks can bear school logos, region-specific designs, or personalized elements—offering value over generic imported notebooks. -

Economic Uplift & Local Employment

Setting up a small manufacturing unit creates employment opportunity in Balukpong and neighbouring villages. It contributes to regional development. -

Scalability & Expansion

Once demand stabilizes, the unit can grow—adding more machines such as hardcover binding or journal-style production. -

Competitive Advantage

Local presence with shorter lead times and lower shipping costs can make your product more competitive in price and service compared to distant suppliers.

6. Selecting a Supplier & Installation Partner

Because Balukpong is relatively remote compared to major metro centres, choosing the right supplier is critical:

-

Vendor Experience: Look for manufacturers who understand working in northeastern India, offering installation, commissioning and training services in remote areas.

-

Shipping & Logistics: Machine size and weight can influence transport cost—choose vendors who can handle delivery to Arunachal Pradesh.

-

Spare-Parts Availability: Ensure the supplier can provide spare parts or send service technicians to Balukpong or nearby towns.

-

Documentation & Warranty: Standard warranty and service terms, with maintenance agreements.

-

Reference Projects: Ask for examples of notebook making machines installed in similar inland or hilly locations.

You may request demonstrations, site surveys, and trial runs. Ask for layout plans and power-load assessments before purchase.

7. Implementation Plan for Balukpong Unit

Here is a suggested phased plan to set up a notebook manufacturing unit in Balukpong:

Phase 1: Feasibility Study

-

Survey demand among nearby schools, colleges, NGOs, coaching centres.

-

Estimate investment budget, location (warehouse or workshop shed).

-

Connect with Arunachal Pradesh industrial development office for permits and incentives.

Phase 2: Procurement & Installation

-

Choose appropriate notebook making machine model.

-

Arrange shipment and customs documentation if required for interstate transport.

-

Prepare workshop floor, power supply (stabilizers, backup generator if required), foundation or platform.

Phase 3: Training & Commissioning

-

Arrange vendor-led operator training for local workforce.

-

Perform trial runs, quality checks, output calibration.

-

Set up routine preventive maintenance schedules.

Phase 4: Production Launch & Marketing

-

Contact local schools, government tenders and stationary dealers.

-

Offer demo samples, custom notebooks with institutional branding.

-

Develop packaging and pricing strategy for notebooks produced locally.

Phase 5: Scale-Up & Quality Assurance

-

Monitor output, yield, defect rate and adjust machine settings.

-

Collect feedback from customers.

-

Plan purchasing additional equipment (e.g. glue binder, spiral binding machine) based on demand.

8. Cost Estimates & Return on Investment (ROI)

While precise costs vary, here is a rough framework for budgeting:

| Item | Approximate Cost* |

|---|---|

| Manual/Semi-Automatic Machine | INR 2-5 lakhs |

| Fully Automatic Capacity Unit | INR 8-20 lakhs |

| Installation / Shipping / Training | INR 50,000 – 2 lakhs |

| Raw Materials (paper, covers, binding wire) | Recurring cost based on volume |

| Labor & Maintenance | Monthly operational cost |

| Space Lease or Shed Construction | Depending on Balukpong land/rent rates |

*Costs are indicative. Obtain quotations from vendors before finalising.

Return on Investment:

Assume you produce 500 notebooks per day at a sale price of INR 25 each. Monthly revenue ~ INR 3.75 lakh. After deducting raw-material, labor, utilities, and maintenance, you may recover capital cost within 1–2 years. ROI improves with higher utilization, institutional contracts, or customization premium.

9. Challenges & Mitigation in Arunachal Pradesh

While notebook manufacturing is promising, you should plan for local challenges:

-

Electricity Supply & Grid Stability:

Remote areas sometimes face outages. Mitigate using backup generator or UPS system. -

Transport & Accessibility:

Heavy machinery transport may be delayed by road quality or weather conditions. Plan for seasonal disruptions during monsoon. -

Workforce Skill Level:

Local operators may need extended training in machine operation, quality control, and safety procedures. -

Raw Material Variability:

Paper moisture content could vary due to humidity. Ensure storage in controlled environment or purchase moisture-resistant raw material. -

Regulatory Compliance:

Understand local safety norms, waste disposal norms (paper/edge scraps), and licensing requirements for manufacturing units.

Conclusion

If you are looking to establish a reliable and efficient notebook manufacturing unit in Balukpong, Arunachal Pradesh, investing in the right notebook production machine is essential. By choosing suitable technology, partnering with vendors who offer installation and training, and planning for local constraints, you can unlock demand from schools, government contracts, and educational institutions in and around your region.

To move forward, begin with a vendor consultation, request machine demos, gather quotes, and evaluate operational layout for your proposed site in Balukpong. With thoughtful planning and implementation, your notebook production initiative can become a sustainable and profitable business — serving the local educational needs while generating employment and adding value to the regional economy

.