Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Pasighat | Automatic & Semi-Automatic Binding Machines | Arunachal Pradesh

Notebook Making Machine in Pasighat | Arunachal Pradesh

The demand for stationery items, especially notebooks, registers and exercise books, continues to grow across India. In remote regions such as Pasighat in Arunachal Pradesh, setting up a notebook production facility can be a viable business opportunity. This article explores the notebook making machine options available for entrepreneurs in Pasighat, outlines the benefits of automatic and semi-automatic systems, discusses cost considerations, installation requirements, and the growth potential within the local market.

If you are planning to start notebook manufacturing in or around Pasighat, understanding the machinery, suppliers, and business dynamics will help you build a strong foundation.

Why Start Notebook Production in Pasighat, Arunachal Pradesh?

-

Untapped Local Market

Arunachal Pradesh currently has limited local manufacturing of stationery products. Many local schools, colleges, coaching centres and small shops obtain notebooks from outside the state. Producing notebooks locally reduces transportation cost, lead time, and import dependency. -

Government & Regional Incentives

State and Central government schemes encourage MSME / agro-processing or rural industry development in remote areas. Incentives for setting up manufacturing units in less industrialised districts may be available. -

Access to Raw Materials & Labour

While raw paper might need to be sourced from paper mills elsewhere, ancillary inputs such as covers, printing and binding labour can be locally managed. Pasighat has access to local workforce and can position itself as a small-scale stationery hub. -

Growing Educational Infrastructure

With increasing schools, coaching centres and literacy initiatives, demand for notebooks is likely to rise. Producing locally gives you control over design, quality, turnaround time and cost.

Because of these factors, investing in a notebook making machine in Pasighat could be a strategic move for entrepreneurs seeking to establish or expand notebook manufacturing in Arunachal Pradesh.

Types of Notebook Making Machine

When planning to set up a notebook production unit around Pasighat, you’ll need to decide which kind of notebook making machine suits your scale and budget. Here are some common types with pros & cons:

| Type | Description | Advantages | Considerations |

|---|---|---|---|

| Semi-Automatic Notebook Making Machine | Manual or partially automated cutting, stitching, folding & edge-squaring | Lower cost, simpler maintenance, suitable for small to medium scale production | Requires some manual intervention, slower throughput |

| Fully Automatic Notebook Making Machine | Integrated machines for cutting, folding, stitching, edge-squaring & sometimes packing | Higher throughput (hundreds to thousands notebooks per hour), consistent quality | Higher initial investment, requires stable power supply, trained operators |

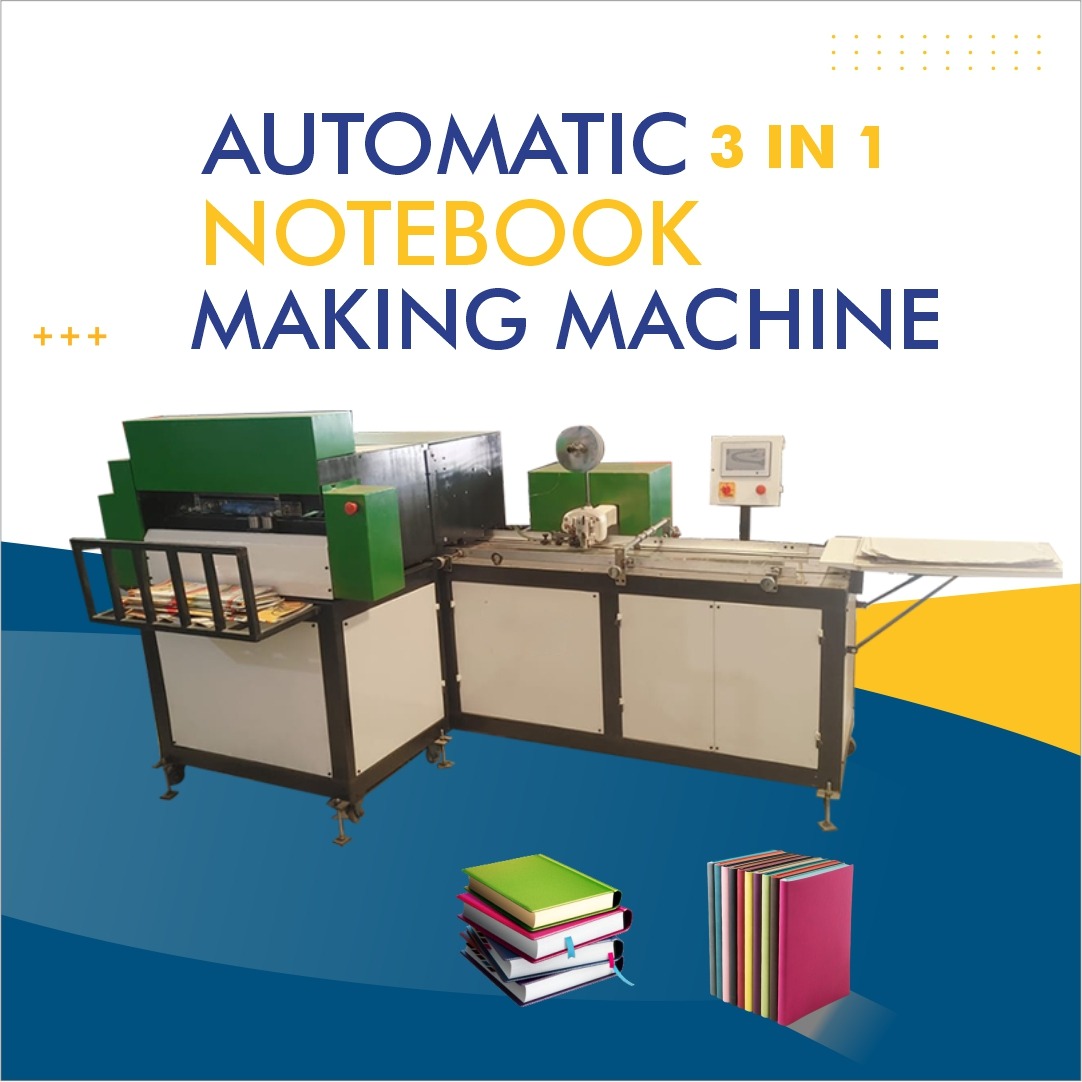

| 3-in-1 or Multi-Function Binding Machine | Machines that combine stitching, folding and edge-squaring into single integrated unit | Saves floor space, reduces manual handling between stages | Less flexibility in customization, may require spare parts and more complex maintenance |

For example, Namibind offers a fully automatic 3-in-1 notebook making machine (stitching / folding / edge squaring) with capacity up to 1,500-2,000 books per hour. namibind.com+1

Similarly, Sujata Machines offers automatic folding-stitch-squaring machines. sujatamachines.in

Another manufacturer, S.K. Engineers, offers automatic or semi-automatic notebook making machines with mid-range cost. skengineer.org+1

Cost & Specification Considerations

If you are planning to procure a notebook making machine for Pasighat, you should evaluate the following factors:

-

Production Capacity

-

How many notebooks per hour/day do you aim to produce?

-

Semi-automatic machines may produce few hundreds per hour; fully automatic machines can reach thousands per hour. namibind.com+1

-

Plan capacity based on local demand plus growth buffer.

-

-

Automation Grade

-

Semi-automatic will cost less initially but have higher labour cost and slower throughput.

-

Fully automatic requires higher capital but lowers per-unit labour cost and increases consistency.

-

-

Machine Footprint, Power & Utilities

-

Fully automatic machines often run on three-phase power (e.g. 440V / 3-phase) and require stable electrical supply. sujatamachines.in+1

-

Space requirement, ventilation, dust control, operator safety must be considered.

-

-

Maintenance & Spare Parts

-

Choose suppliers who provide service / spare parts support.

-

If sourcing from outside Arunachal Pradesh, plan logistics for spare parts shipments to Pasighat.

-

-

Cost Range / Investment

-

Prices vary depending on brand, automation and capacity. For example, some fully automatic notebook making machines are priced around ₹8-10 lakhs or more. namibind.com+1

-

Semi-automatic machines cost less; entry-level equipment may start in the range of a few lakhs of rupees. smallbusinessolution.com+1

-

Also budget for installation, operator training, raw material (paper, covers, ink), packaging and working capital.

-

-

Raw Material & Packaging Cost

-

Cost of paper sheets, cover board or laminated covers, binding wire or staples, plastic wrap or shrink packaging.

-

Logistics cost of transporting raw materials to Pasighat.

-

-

Regulatory Compliance & Licensing

-

Local municipal / district licensing, safety and electrical certifications, pollution / waste disposal norms (paper dust, waste off-cuts).

-

GST registration, MSME registration, trade license for manufacturing unit in Pasighat.

-

Setting Up a Notebook Production Facility in Pasighat

Below is a step-by-step outline of setting up a notebook making / stationery manufacturing unit near Pasighat, Arunachal Pradesh:

-

Feasibility Study & Business Plan

-

Survey local demand: schools, coaching institutes, shops. Estimate monthly requirement of notebooks.

-

Estimate competing supply from outside the state. Identify price per unit and quality standards.

-

Project scale: small (few hundred per day), medium (1,000-3,000 per day), or larger scale.

-

-

Select Suitable Machinery

-

Choose between semi-automatic or fully automatic notebook making machine based on your production target and capital.

-

Source quotations from reputable suppliers (for example Namibind, Sujata / Sujata Machines, SK Engineers, Kesya International). kesyainternational.com+3namibind.com+3sujatamachines.in+3

-

Compare features: capacity (books per hour), size flexibility (A4 / A5 / custom sizes), binding type, speed, power spec, cost.

-

-

Location & Infrastructure Setup

-

Select a workshop or factory space near Pasighat (or in adjacent industrial area).

-

Ensure stable three-phase electric supply (or upgrade electrical infrastructure).

-

Ensure flooring, ventilation, lighting, worker amenities, fire safety.

-

Plan waste disposal (paper off-cuts), and consider environmental regulations.

-

-

Procure & Install Machines

-

Place order with supplier. Plan delivery to Pasighat (transportation cost).

-

Arrange installation & commissioning. May require supplier support or technician visit.

-

Train operators / staff in operation, safety, maintenance.

-

-

Raw Materials & Supply Chain

-

Arrange supply of inner pages (ruled or plain paper), covers (cardboard / laminated covers), binding staples or wire, packaging materials.

-

Negotiate with nearby paper distributors or import from larger paper-roll suppliers in Assam / neighboring states.

-

-

Production Process Flow

-

Step 1: Cutting paper sheets to required size.

-

Step 2: Folding / stitching / binding (using the binding machine).

-

Step 3: Edge-squaring to produce neat finished edges.

-

Step 4: Packaging (bundling notebooks or wrapping for retail).

-

Step 5: Quality checking and dispatch to local shops / institutions.

-

-

Marketing & Sales Channels

-

Target local schools, college bookstores, coaching centres in Pasighat & nearby towns.

-

Offer customization: cover design, ruled lines, page count.

-

Tie-up with retail stationery shops.

-

Use digital presence: website listing, local directory, orders by phone or WhatsApp.

-

-

Scaling Up & Diversification

-

Once stable, scale production by adding additional shifts or machine modules.

-

Diversify product portfolio: hardcover notebooks, diaries, customised planners.

-

Explore supply to neighbouring districts in Arunachal Pradesh and Assam.

-

Challenges & Risk Mitigation

While notebook manufacturing in Pasighat offers strong potential, you should beware of certain challenges:

-

Power Reliability: Remote regions may suffer from fluctuations in electrical supply. Consider backup UPS / stabilizer or diesel generator if needed.

-

Transportation & Logistics: Procurement of raw materials (paper rolls, covers) might incur high transport cost to reach Pasighat. Plan buffer inventory.

-

Skilled Labor: Operating fully automatic machinery may require some technical training. Ensure you have staff who can manage machine maintenance, troubleshoot breakdowns.

-

Competition & Pricing Pressure: Larger stationery brands or suppliers may offer lower prices at scale. Your advantage will be local availability, customization, lower lead-time.

-

Regulatory / Environmental Norms: Dispose paper waste responsibly. Keep compliance with local municipal laws, fire safety regulations, and industrial safety standards.

-

Machine Downtime Risks: Ensure spare parts availability, timely maintenance, to avoid production stoppage.

Mitigation strategies include keeping buffer stock of spares, periodic preventive maintenance schedule, arranging alternate raw-material sources, and maintaining good relationships with your supplier for after-sales service.

Why Choosing a Quality Notebook Making Machine Matters

Investing in a good quality binding machine or notebook making system has long-term impact on your business:

-

Product Quality & Finish: A reliable machine yields cleaner cuts, consistent stitching, and neat edge squaring which enhances the look and durability of notebooks.

-

Operational Efficiency: Higher automation reduces manual labour cost, speeds up production, and lowers defect rate or wastage.

-

Scalability: With the right capacity and modular setup, you can scale up as demand grows (e.g. expanding to neighbouring districts).

-

Brand Reputation: Consistent product quality helps you secure repeat orders from schools and stores.

-

Return on Investment (ROI): Although cost of a high-capacity automatic notebook making machine is higher, per-unit production cost falls with scale, improving profit margins.

Conclusion

Setting up a notebook making machine in Pasighat, Arunachal Pradesh offers a promising opportunity for entrepreneurs today. With growing local demand, potential incentives for rural manufacturing, and the right equipment, you can build a scalable and sustainable notebook manufacturing business in this region.