Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

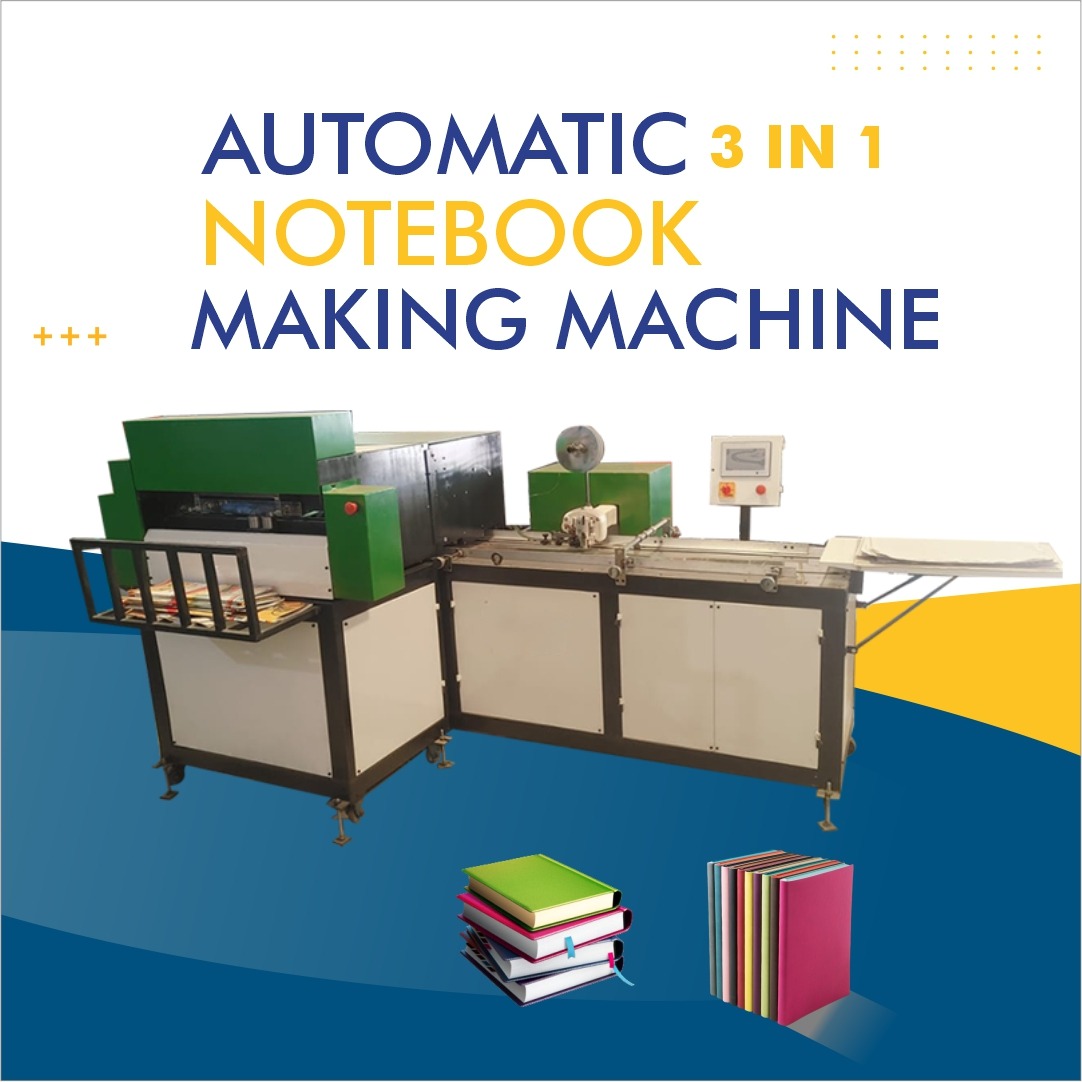

Notebook Making Machine Supplier in Palakollu | Andhra Pradesh Notebook Machine Manufacturer

Notebook Making Machine in Palakollu | Andhra Pradesh

If you are looking for a high-quality notebook making machine in Palakollu, Andhra Pradesh, you’ve come to the right place. Our facility designs, manufactures, and supplies top-tier automatic notebook making machines that cater to educational, commercial, and industrial notebook production needs. With years of experience in notebook manufacturing equipment, we ensure you receive reliable performance, superior build quality, and excellent after-sales support.

This comprehensive guide introduces you to our notebook manufacturing machine capabilities, the benefits of investing in automated production equipment, and why choosing a manufacturer based in Palakollu makes strong business sense.

Why Choose a Local Manufacturer in Palakollu

Strategic Location

Palakollu, nestled in the West Godavari district of Andhra Pradesh, is well positioned for logistics, availability of skilled labor, and access to local suppliers. This offers lower transportation costs and faster turnaround times compared to importing equipment from distant regions.

Cost Advantages

Local production reduces import duties, handling charges, and extended delivery delays. By choosing a notebook machine manufacturer in Palakollu, you gain the advantage of competitive pricing without compromising quality.

Tailored Solutions

Working with a local manufacturer allows you to customize specifications according to your production volume, sheet sizes, paper thickness, binding types, and automation requirements. Your notebook making machine can be adapted to your factory layout for optimal workflow.

After-sales Support

Proximity ensures faster maintenance service, timely spare parts supply, on-site technical support, and quicker calibration or upgrades. This reduces downtime and enhances productivity.

Our Notebook Manufacturing Machines

As a leading notebook making machine supplier in Andhra Pradesh, we offer a range of robust and scalable equipment. Below are the core types you can select from or customize:

1. Automatic Notebook Making Machine

Our automatic notebook making machine includes features such as high-speed sheet feeding, trimming, binding, hot‐melt or glue binding, cover wrapping, and stacking. It automates most manual operations, reducing labor costs and improving consistency.

Key Specifications:

-

Production rate: 300–1500 notebooks per hour

-

Sheet size range: A4, A5, custom sizes

-

Binding types: stitched binding, glue binding, perfect binding

-

Control system: PLC based touch panel interface

2. Semi-Automatic Notebook Manufacturing Machine

Ideal for small to medium scale workshops, this semi-automatic model allows manual loading of paper stacks while automating trimming, binding, and stacking operations. It bridges the gap between traditional manual binding and full automation.

3. Paper Binding Machine for Notebook Production

To complement the notebook production line, our paper binding machine offers reliable binding of assembled sheets with cover, trimming edges, and pressing. This equipment ensures that each notebook meets finish quality standards for edge alignment and binding strength.

4. Book Binding Equipment for Educational Notebooks

Our book binding equipment is suited for assembling spiral-bound or stitched-bound books, like exercise books, test-books, or lab-manual notebooks. These machines can be configured to integrate with the main notebook making line or operate as standalone units.

5. Custom Notebook Production Equipment

We understand that every production facility is different. We offer customization in:

-

Number of station heads

-

Binding method (thread stitching, stapling, adhesive glue)

-

Cover printing and lamination integration

-

Stacker capacity and output tray specification

-

Automation level (manual to fully automatic linking)

Technical Features & Advantages

Durability and Build Quality

Crafted from heavy-duty steel frames and precision machined parts, our notebook making machine offers long-term stability in high-volume production. All moving components are properly balanced and vibration-tested for smooth operation.

User-friendly Controls

Modern PLC-based control panels provide simplified interface for speed adjustment, error alerts, job memory settings, and safety lockouts. This ensures even non-technical operators can handle the equipment with minimal training.

Energy Efficiency

Our automatic systems are optimized for low power consumption through variable-frequency drives and efficient motors. This reduces electricity costs and lowers the total cost of ownership.

Quality Assurance

Each notebook manufacturing machine undergoes rigorous quality checks, including trial runs using real paper stock, alignment tests, binding strength checks, trimming accuracy, and output sampling to meet strict tolerances.

Scalability

Whether you’re producing a small batch of custom notebooks or scaling up to meet institutional demand, our machines scale with your business growth. Additional modules or upgrades can be retrofitted easily.

Applications and Markets

Educational Institutions

Schools, colleges, coaching centers, and vocational training institutes in and around Andhra Pradesh prefer purchasing local notebook production equipment. This helps them produce branded exercise books, test-series series notebooks, and academic material in-house.

Printing & Publishing Houses

Local printers can expand their offerings by adding notebook production capabilities. Instead of outsourcing binding, they can process medium-run notebook orders using their existing premises streamlined by our equipment.

Stationery Manufacturers

Small-scale stationery brands can invest in a compact notebook making machine to launch private-label notebooks under their own brand. This improves margins and reduces turnaround time.

Corporate and Institutional Buyers

Organizations that supply promotional materials or corporate journals can benefit from integrated binding solutions without relying on external suppliers. In-house production ensures confidentiality and customized finish.

Installation, Training and Aftercare

Delivery and Installation

Once the order is confirmed, we handle logistics from our workshop to your facility in Palakollu or surrounding areas. Professional installation ensures leveling, electrical wiring, alignment, and trial-production within your environment.

Operator Training

We provide on-site training for your operators and maintenance team covering machine safety, changeover from one job-size to another, routine maintenance, troubleshooting common faults, and preventive servicing.

Spare Parts and Maintenance Contracts

We maintain a stock of critical spare parts for binding heads, trimming blades, belts, drive components, and sensors. Optional maintenance contracts are available to ensure timely servicing and minimize downtime.

Upgrades and Retrofits

As production demands increase, you may require higher throughput or new binding types. We support upgrades such as additional binding modules, faster sheet feeders, and modular control features.

Costing and Return on Investment

Pricing Factors

The cost of a notebook making machine depends on the following parameters:

-

Production capacity (notebooks per hour)

-

Level of automation (manual / semi-automatic / fully automatic)

-

Binding method complexity

-

Customization in size range and control features

-

Additional modules for printing, lamination, or cover handling

ROI Calculation

With an efficient notebook manufacturing machine, you can:

-

Reduce per-unit labor cost

-

Improve yield (less waste trimming)

-

Shorten lead time for orders

-

Increase acceptance by delivering consistent quality

If your facility runs multiple shifts and produces hundreds to thousands of notebooks daily, the payback period is typically between 12 to 24 months, depending on utilization and pricing of inputs like paper, glue, and electricity.

Comparison with Other Suppliers

| Feature | Our Machine (Palakollu Manufacturer) | Imported Alternatives |

|---|---|---|

| Delivery Time | Weeks | Months |

| Transport Cost | Lower (local delivery) | Higher (shipping + import fees) |

| After-Sales Support | On-site support from local team | Remote support, delayed response |

| Customization | Full customization per size and binding method | Limited by standard models |

| Price | Competitive without import duty | Higher cost due to duty and markup |

By selecting a local notebook machine manufacturer, you gain in responsiveness, lower total cost, and better alignment with your production needs.

How to Proceed

-

Consultation: Share your production requirements — size formats, binding types, output capacity, and budget.

-

Proposal & Drawing: We will propose a configuration with layout drawing, modular component list, and estimated cost.

-

Order Confirmation: Upon approval, a contract is signed, and production begins at our workshop.

-

Manufacturing & Testing: The notebook making machine is built, tested, and trial runs are done with your sample job.

-

Delivery & Training: Installation at your site, operator training, and commissioning.

-

Support & Maintenance: Ongoing servicing, spare supply, and upgrade options.

Conclusion

A reliable notebook making machine is critical for any facility aiming to produce notebooks at scale with consistency and quality. Our automated and semi-automated notebook manufacturing machines combine robust engineering with flexible customization to support educational institutions, printers, stationery brands, and corporate users.

Being based in Palakollu, Andhra Pradesh gives you the strategic advantage of proximity, lower cost, and local support. Contact us today with your specifications to get a tailored proposal and begin building your in-house notebook production capability.