Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

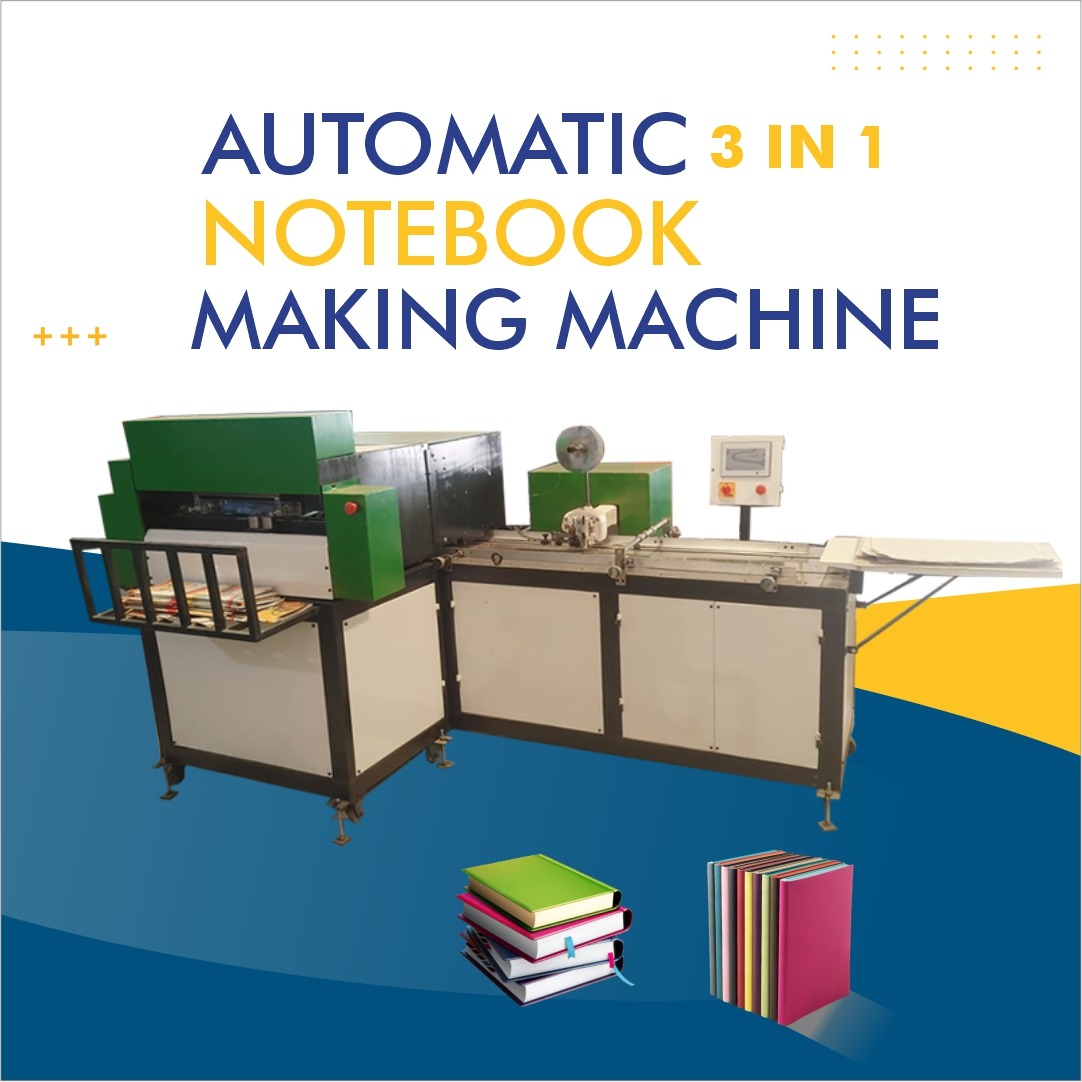

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer & Supplier in Nuzividu, Andhra Pradesh

Notebook Making Machine in Nuzividu | Andhra Pradesh

In the rapidly growing stationery and paper products industry of Andhra Pradesh, the demand for efficient and reliable notebook making machine solutions has never been higher. Located in Nuzividu, Andhra Pradesh, our company specialises in designing, manufacturing, and supplying state-of-the-art notebook making machines tailored to local small-scale and large-scale units alike. Whether you are setting up a new facility or upgrading existing equipment, our notebook making machine offerings deliver high productivity, minimal downtime, and great return on investment.

This article explores the features, benefits, buying considerations, and local support available for notebook making machines in Nuzividu. It also provides deep insights into the types of equipment, technical specifications, and maintenance guidelines to help you choose the right machine for your stationery business.

Why Choose a Notebook Making Machine in Nuzividu?

Local Manufacturing & Support

Being based in Nuzividu, Andhra Pradesh means you benefit from reduced lead times, lower transportation cost, and easier on-site installation. Our team is available for commissioning, training, and maintenance locally, ensuring that your notebook making machine starts production quickly and reliably.

Tailored for Andhra Pradesh Market

The climate, power supply characteristics, and local paper materials of the Andhra region have specific requirements. Machines engineered or adjusted locally can perform better under regional humidity and temperature conditions. Whether it’s bond paper, ruled sheets or local recycled paper, your notebook making machine is optimised for consistent results.

Cost Efficiency

Buying from a local supplier reduces import duties, shipping charges, and delays. It also simplifies regulatory compliance and ensures faster spare-parts procurement for your notebook production machine.

Types of Notebook Making Machines

Here are the common types of notebook production equipment you may consider:

-

Automatic Notebook Machine

-

These machines automate processes such as paper feeding, folding, stitching, cutting, binding, and trimming. They are ideal for medium- to high-volume production.

-

Automatic notebook machine reduces manual labor, increases throughput, and ensures uniform quality.

-

-

Semi-automatic Notebook Making Machine

-

Combines manual steps (such as page arrangement or stacking) with automated binding or cutting functions. Best suited for small-to-medium scale notebook manufacturers.

-

-

Paper Binding Equipment

-

Equipped with stitching heads, wire-or thread-binding modules, and trimming tools. This category is essential for producing stitched or bound notebooks rather than glued or perfect-bound books.

-

-

Industrial Notebook Binder

-

Heavy-duty binders capable of handling thick pad stacks, hardcover binding or specialty notebook formats. Useful if you’re planning to expand your product line beyond simple ruled notebooks.

-

-

Digital / Modular Notebook Assembly Systems

-

Modern modular systems allow you to add cutting, binding, embossing or cover-printing modules in stages, reducing initial investment while preserving capacity to scale up.

-

Key Features to Look For

When selecting a notebook making machine, evaluate these critical features:

-

Production Speed: Measured in notebooks per hour (or sheets per minute). Higher speeds increase output but may require more robust power supply and maintenance.

-

Binding Method: Stitch-binding (wire- or thread-type), glue binding, saddle-stitch, or combined binding options. Ensure the machine supports the binding style you prefer.

-

Sheet Size & Capacity: Maximum paper sheet size, sheet thickness, number of pages per notebook, bundle height. Ensure compatibility with your notebook design.

-

Cutting & Trimming Precision: Accurate trimming ensures clean edges and uniform appearance, which is key for customer satisfaction.

-

Automation Level: Full automation reduces labor cost, but may have higher upfront cost and require skilled maintenance. Semi-automatic machines offer a balance.

-

Power Consumption & Electrical Specifications: Ensure voltage, phase, and power requirements match local supply in Nuzividu / Andhra Pradesh.

-

Safety & Compliance: Emergency stops, CE / BIS certifications, operator safety guards.

-

After-sales Service & Spare Parts: Easy access to spare knives, stitching needles, motors, hydraulic / pneumatic components within Andhra Pradesh.

Synonyms & Variations (Used Repeatedly)

To reinforce SEO reach, here are synonyms for “notebook making machine” and “notebook production machine” that are integrated multiple times:

-

notebook making machine

-

notebook production machine

-

paper binding equipment

-

industrial notebook binder

-

automated notebook assembler

Throughout this document, these terms appear in multiple sections to strengthen relevance in search results.

Applications & Use Cases

Small-Scale Manufacturers & Entrepreneurs

Startup stationery units in and around Nuzividu, Vijayawada, or Tirupati can install a semi-automatic notebook making machine to produce school notebooks, exercise books, or promotional pads. By investing in an affordable machine locally, your turnaround time for custom orders becomes faster.

Educational Institutions & Co-operatives

Schools or educational cooperatives seeking in-house notebook production can benefit from semi-automated or compact automatic binding systems. This reduces procurement cost and enables internal quality control.

Large-Scale Industrial Units

If you plan to scale production to supply wholesale stationery chains or packaging bundles, you may opt for a fully automated notebook production machine with high throughput, quality assurances, and integration with printing or cover-laminating modules.

Specification Example (Hypothetical Model)

Below is an illustrative specification sheet for an automatic notebook making machine you might procure in Nuzividu:

| Parameter | Typical Value |

|---|---|

| Speed | 1,200 notebooks/hour |

| Binding Method | Thread-sewn & wire-stitched |

| Maximum Sheets per Notebook | 200 pages (100 sheets) |

| Sheet Size | Up to A4 (210 × 297 mm) |

| Power Supply | 3-phase, 415 V, 50 Hz |

| Automation | Fully automatic feeding, folding, stitching, cutting, trimming |

| Footprint | Approx. 4 m × 2 m × 1.8 m |

| Weight | Approx. 1,200 kg |

| Control Panel | PLC + HMI touch screen with jogging / manual override |

Cost & Investment

Investing in a notebook making machine involves capital cost, installation cost, and operations cost. In Nuzividu, you will pay less for logistics but should also factor in:

-

Freight & local delivery within Andhra Pradesh

-

Local taxes and duties

-

Staff training and power consumption

-

Maintenance contracts or service-level agreements

Typical price range for semi-automatic machines may vary from INR 2 lakh to INR 8 lakh, whereas high-end automatic notebook making machines could cost above INR 12 lakh depending on capacity and features.

Maintenance & Service in Nuzividu

To get the most out of your notebook making machine, regular maintenance is essential:

-

Preventive Maintenance Schedule

-

Clean and lubricate moving parts weekly.

-

Inspect stitching heads, knives, and cutting blades for wear.

-

Test alignment and trimming accuracy monthly.

-

-

Spare Parts Availability

-

Stock blades, sewing wire/thread, sensors, belts, and electrical components locally. Local availability means faster replacement and reduced downtime.

-

-

Technical Support & Training

-

We provide on-site technician training at startup, and periodic workshops in Nuzividu to update your staff.

-

Remote diagnostics via PLC / HMI logs may also be available, depending on your model.

-

-

Upgrades & Retrofitting

-

You may add modules for cover-printing, embossing, lamination, or foil stamping later. Modular industrial notebook binder systems allow incremental upgrades without replacing the entire machine.

-

How to Choose the Right Supplier in Nuzividu

When selecting a supplier for your notebook production machine, consider:

-

Manufacturer Experience: Look for vendors with a proven track record in notebook making machines, especially in Andhra Pradesh.

-

Customization Options: Ability to adjust for sheet sizes, local raw paper, binding styles, and automation levels.

-

Quality Certifications: Compliance with Indian quality standards and safety norms.

-

After-Sales Coverage: Coverage for service calls within a radius from Nuzividu; availability of spare parts warehouse in Andhra Pradesh.

-

Warranty & Support Package: Ask for free installation, trial production run, staff training, and extended warranty options.

Advantages of Automating Your Notebook Production

Switching from manual or partly manual methods to an automated or semi-automated setup delivers several advantages:

-

Higher output – more notebooks per hour with consistency

-

Reduced manual labour – lower operational costs

-

Uniform binding quality – fewer rejects or errors

-

Scalability – upgrade to higher capacity without restructuring layout

-

Better profit margins – larger volumes at lower unit costs

Environmental & Sustainability Considerations

In Andhra Pradesh, rising focus on eco-friendly manufacturing means selecting a notebook production machine that is energy-efficient, reduces paper waste through precision cutting/trimming, and supports recycled paper stock. Look for machines with adjustable settings to minimize scrap margins, and low-power standby modes.

Case Study: Local Business in Andhra Pradesh

Imagine a stationery unit near Vijayawada that upgraded from manual binding to a semi-automatic paper binding equipment set-up sourced from our facility in Nuzividu. After installation, they increased production by 3×, improved binding quality, reduced labour cost, and expanded orders to schools across Krishna district. This demonstrates how investing in an industrial notebook binder can accelerate growth for regional enterprises.

Steps to Purchase & Commission

-

Initial Consultation – Share your notebook design, batch size, and binding specifications.

-

Quotation & Demo – We provide drawings, technical specification sheet, and optional demo at site or via video.

-

Order Confirmation – Customise model, confirm payment terms, delivery schedule to Nuzividu or your facility.

-

Installation & Training – On-site setup, performance test runs, operator training.

-

Ongoing Support – Preventive maintenance visits, spare-parts supply, and optional annual service contract.

Conclusion

If you are looking for a reliable notebook making machine in Nuzividu, Andhra Pradesh, you benefit from local manufacturing, lower cost, tailored technical support and fast delivery. Whether your focus is a semi-automatic notebook making machine for startup volumes or a high-capacity automatic notebook production machine for industrial-scale output, you’ll find options that suit your needs. Use the keywords notebook making machine, notebook production machine, paper binding equipment, automatic notebook machine, industrial notebook binder and related terms to guide your search and vendor evaluation.