Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

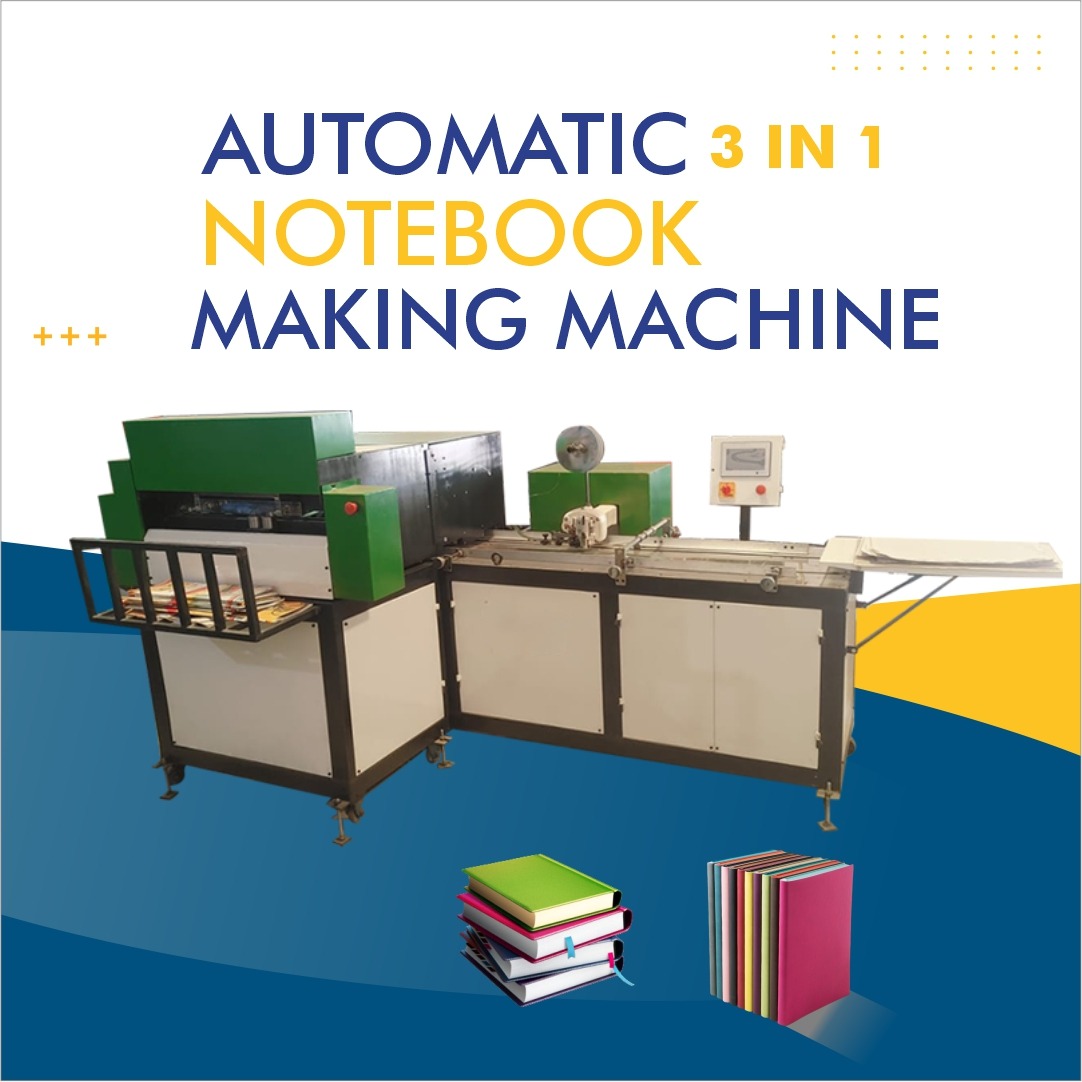

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier & Fabricator | Narasaraopeta, Andhra Pradesh

Notebook Making Machine in Narasaraopeta | Andhra Pradesh

If you are searching for a notebook making machine in Narasaraopeta, Andhra Pradesh, you’ve come to the right place. Whether you run a small stationery business, a school printing unit, or a mid-sized manufacturing facility, selecting a reliable machine is critical for output quality, productivity, and long-term service life. In this detailed guide, we’ll walk you through everything you need to know about notebook making machines – from types, features, benefits, and local service support – to help you make an informed decision.

What Is a Notebook Making Machine?

A notebook making machine is a piece of industrial equipment that automates the process of producing notebooks. It can perform tasks such as:

-

Cutting paper sheets to required dimensions

-

Collating pages into sets

-

Binding pages using stitching, glue, or spiral coil

-

Pressing the edges to ensure flatness

-

Trimming excess cover edges

These machines are also known by similar terms such as book binding machine, paper binding equipment, or binding press machine depending on the binding technique used. The core objective is to improve productivity while maintaining consistent quality in notebook production.

2. Types of Notebook Making Machines

Depending on your production volume and binding preferences, you may consider the following types:

2.1 Manual or Semi-automatic Binding Machines

-

Suitable for smaller production runs

-

Lower capital cost, simpler operation

-

Ideal if you already do some manual finishing such as trimming or cover pasting

2.2 Fully Automatic Notebook Making Systems

-

Integrated machines that handle sheet cutting, folding, stitching, and trimming

-

Higher throughput per hour

-

Requires stable power supply, skilled operator training

-

Perfect for medium-to-large operations, or if you plan to scale your business

2.3 Stitching / Thread-sewing Machines

-

Known also as stitching machine or book binding machine

-

Uses wire or thread staples to secure pages

-

Durable binding suitable for school notebooks or ruled pads

2.4 Spiral or Wire-O Notebook Binding Equipment

-

Sometimes referred to as spiral notebook maker

-

Inserts coils or wire loops along a punched edge

-

Offers professional finish and ease of page turning

2.5 Perfect Binding or Glue-Binding Systems

-

Uses adhesive along the spine instead of staples or stitching

-

Ideal for thicker notebooks, diaries, or soft-cover booklets

2.6 Sheet Cutting & Trimming Machines

-

Essential component in any notebook production line

-

Ensures pages are cut to precise size before binding

-

Also known as sheet cutting machine

Each of these units may be part of a modular system or integrated in one automated line depending on your budget and output requirement.

3. Why Choose a Local Supplier in Narasaraopeta, Andhra Pradesh?

3.1 Proximity & Quick Support

Choosing a notebook making machine supplier in Narasaraopeta or within the Guntur district ensures faster on-site installation and after-sales service. Local suppliers understand regional power conditions, available spare parts, and compliance requirements.

3.2 Customisation & Adaptation

Local fabricators and vendors can customize dimensions (page size, wire gauge, stitching type) to match Andhra Pradesh school textbook specifications or local market preferences. You can request custom binding press machine features such as adjustable clamps or special folding mechanisms.

3.3 Cost Advantage

Sourcing equipment locally often reduces shipping cost, duties, and delays. You may save on transportation, packaging, or import-related overheads compared to buying from far-away factories.

3.4 Compliance & Regulation

Machines built or sold locally will likely adhere to regional safety standards, electrical ratings, and quality control norms applicable in Andhra Pradesh. Warranty and servicing agreements are easier to enforce when the vendor has an office or workshop nearby.

3.5 Local Industry Network

A local supplier may already have customers such as printing presses, publishing houses, or stationery units in Narasaraopeta or neighbouring towns. That means proven reliability and recommendations within your business community.

4. Key Features to Look For

When evaluating a notebook making machine, consider these technical and functional features:

-

Sheet Size Compatibility: Ability to handle various page sizes (e.g. A4, A5, custom ruled lines).

-

Production Capacity: Pages or notebooks per hour; number of cycles per minute in automatic systems.

-

Binding Type: Stapling, stitching, coil binding, glue binding, or hybrid.

-

Automation Level: Manual, semi-automatic, automatic feeders, stacking trays.

-

Cutting Precision: High-accuracy trimming to ensure clean edges without paper dust.

-

Material Quality: Use of industrial-grade steel, reliable motors, engineered clamps.

-

Power Consumption & Safety Features: Electrical rating, overload protection, safety interlocks.

-

Ease of Maintenance: Availability of spare parts (knives, blades, binding wires), quick changeover.

-

Upgradability: Ability to scale or integrate additional modules later (e.g. bolster module for diaries, extra trimming unit).

These factors directly influence efficiency, maintenance cost, and product quality for your notebook production venture.

5. Maintenance & After-Sales Service

To keep your machine running smoothly and ensure long-term productivity, you should evaluate:

5.1 Service Agreement

Ask for preventive maintenance contracts with your vendor. Local servicing engineers can visit your site in Narasaraopeta periodically for lubrication, alignment checks, and wear-and-tear audits.

5.2 Spare Parts Availability

Ensure spare blades, binding wire or staples, glue rollers (if applicable), and motor units are easily available nearby. A good local supplier stocks consumables.

5.3 Operator Training

For automatic systems especially, ensure the supplier provides onsite training for operator staff on setup, safety, and cleaning procedures.

5.4 Repair Response Time

One of the major benefits of local presence is reduced downtime. A malfunctioning stitching machine or binding press can delay deadlines; local technicians ensure faster turnaround.

5.5 Warranty & Upgrades

Make sure your supplier offers transparent warranty terms. Also check if your machine can be upgraded later (e.g. adding extra trimming module or higher capacity feeder).

6. Cost, ROI & Scalability

When planning investment in a notebook making machine, consider:

-

Initial Capital Cost: Price of base machine + any add-on modules for cutting, stitching, trimming.

-

Operating Cost: Power, consumables (wire staples or glue, trimming blades), labour.

-

Throughput Rate: How many notebooks per day or per hour you can realistically achieve.

-

Break-Even Timeline: Based on your selling price per notebook, monthly volume, and maintenance cost.

-

Scalability Potential: If you grow your business, can the same machine handle higher load or be expanded with additional modules?

By modeling your cash flows, you can estimate the time to recover your investment—often within 12 to 24 months for medium-volume production units if machine uptime is high and material wastage is minimal.

In many cases, choosing an automatic notebook machine instead of a purely manual or semi-automatic alternative pays off sooner thanks to labour saving and higher throughput per shift.

7. Leading Manufacturers & Vendors Near Narasaraopeta

While you seek a local supplier, here are some practical steps:

-

Search in Guntur district or neighbouring industrial areas for sheet metal fabricators who handle binding equipment.

-

Visit stationery fairs or printing-equipment expos in Andhra Pradesh to compare machine specifications.

-

Ask for past customer references in or near Narasaraopeta to review performance history.

Because of the regional proximity, ensure that your vendor is willing to deliver, install, and commission the machine at your facility in Narasaraopeta.

8. Case Study Example

Imagine a stationery unit in Narasaraopeta wants to produce 2,000 ruled notebooks per day. They decide to invest in a semi-automatic binding press machine combined with an automatic feeder and trimming station. Over a 26-working-day month, they expect output of ~52,000 notebooks.

-

Their operating cost includes labour, electricity (Andhra Pradesh tariff), cutting blades replacement, binding wire staples.

-

Over a year, they generate sufficient margin to pay off the machinery within 18 months.

-

By collaborating with a local supplier, downtime for repair limited to 1–2 days per quarter compared to external vendor which would take week-level delays. This reliability translates into better on-time delivery to school book-demand cycles in the region.

Such a scenario demonstrates how choosing a notebook making machine with local servicing and robust features can materially improve productivity in Narasaraopeta.

9. Frequently Asked Questions (FAQ)

Q1: Can I upgrade a semi-automatic stitching machine to full automation later?

A: It depends on vendor modular design. Some binding press machine models allow you to add automatic feeders or trimming units later if purchased from a flexible manufacturer.

Q2: Is it expensive to maintain cutting blades and spare parts?

A: No, if you source from a local supplier in Andhra Pradesh. Because parts are locally manufactured or stocked, replacement cost and delivery times are modest.

Q3: What level of electricity connection is needed?

A: Automatic notebook making machines often require three-phase power. Verify the vendor’s specifications and ensure your facility in Narasaraopeta has compatible supply and backup (e.g. generator or stabiliser).

Q4: What is typical lead time for delivery and installation?

A: Local fabricators typically quote delivery within few weeks, including commissioning and operator training, because they can ship by road and provide on-site setup.

Q5: Do I need to get any license or approval for running a notebook production unit?

A: Generally, for small scale manufacturing in Andhra Pradesh, you should check municipal regulations, especially if using adhesives or chemicals. But binding machines per se do not require special permits beyond industrial electrical safety compliance.

Conclusion

Investing in a reliable notebook making machine in Narasaraopeta, Andhra Pradesh offers significant advantages — from improved productivity and consistent quality to lower maintenance downtime and faster support. By choosing a local supplier that understands regional needs and offers customizable solutions, you can build a strong foundation for your stationery or printing business.

To get started:

-

Prepare detailed specifications of your output (notebooks per day / size / binding style).

-

Contact “notebook making machine” suppliers or fabricators in or near Narasaraopeta.

-

Request a demo or factory visit.

-

Compare quotes including installation, training, warranty, and spare-parts terms.

-

Ensure you have compatible power supply and operator training in place.