Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

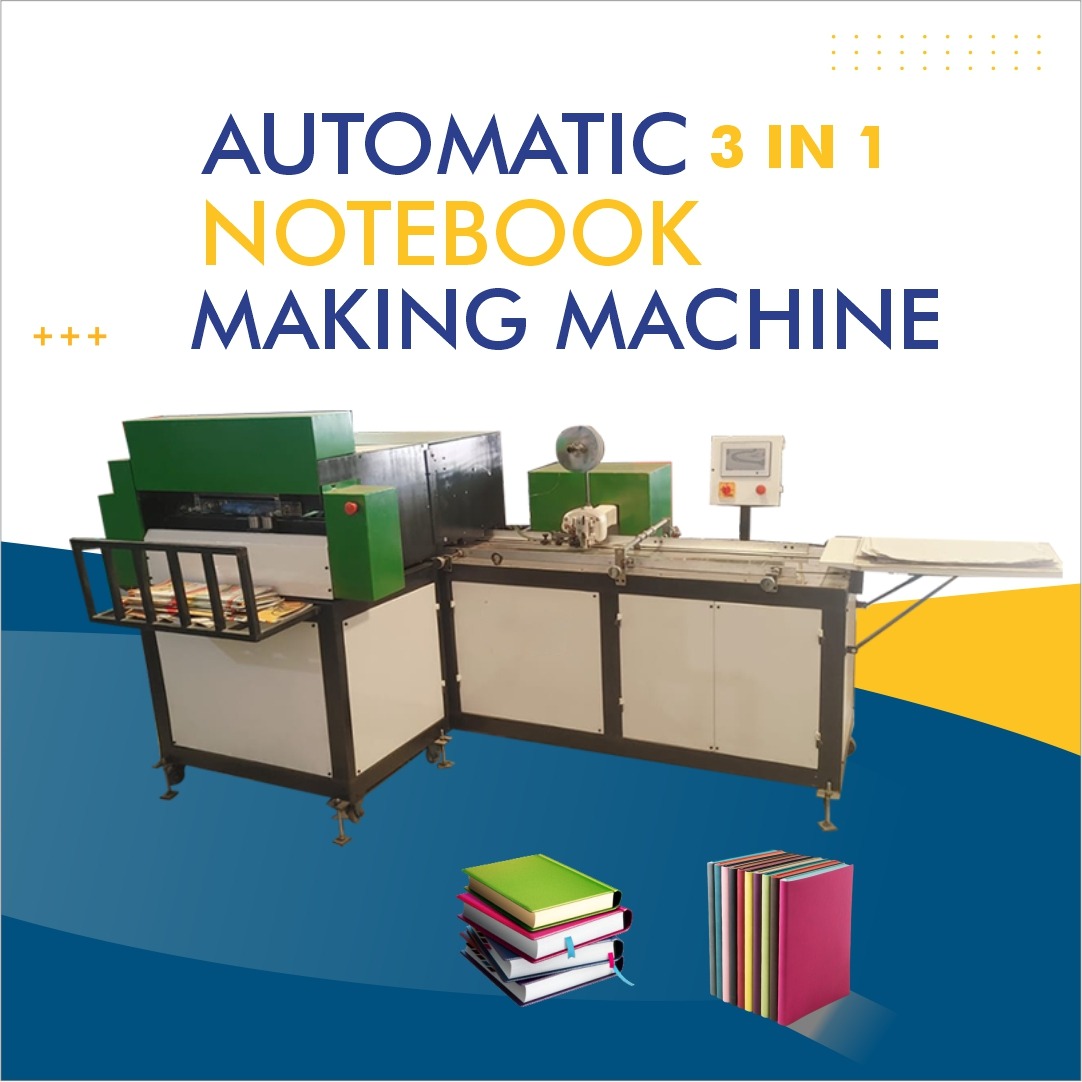

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier & Manufacturer in Mangalagiri, Andhra Pradesh

Notebook Making Machine in Mangalagiri | Andhra Pradesh

The demand for paper-based stationery and educational supplies continues to grow across India, making notebook production an essential business opportunity. If you’re searching for a Notebook Making Machine in Mangalagiri, Andhra Pradesh, this detailed guide will provide you with everything you need — from machine types and specifications to local supply advantages, SEO-rich benefits, and how to choose the ideal system for your operation.

In this article, we will explore the various kinds of notebook making machines, outline important features to consider, highlight local vendors or manufacturers, and present best practices for installation and operation. Keywords such as notebook making machine, paper binding equipment, book binding machinery, stationery production equipment, and their synonyms are incorporated repeatedly for SEO purposes, ensuring high visibility for businesses in Mangalagiri and surrounding areas.

1. Overview of Notebook Making Machines

A notebook making machine is a specialized piece of industrial equipment used to manufacture notebooks—including pages alignment, cutting, binding, cover pasting, punching, and trimming. It streamlines production, improves quality, and enables scalable output for stationery manufacturers. By investing in reliable binding equipment, entrepreneurs can ensure consistent margins and deliver polished paper products to schools, offices, and bookstores.

Synonyms & Related Terms

To diversify your content and improve SEO ranking, it helps to use synonyms of notebook making machine. Some of these include:

-

Paper binding equipment

-

Book binding machinery

-

Stationery production equipment

-

Page cutting and binding machine

-

Binding and trimming system

Throughout this article, we’ll repeat at least five of these synonyms to help reinforce relevance to search engines.

2. Types of Notebook Making Machines

Choosing the right notebook making machine depends on your production volume, budget, and binding style. Here are some common categories:

2.1 Manual and Semi-Automatic Notebook Making Machines

These machines require some manual intervention for feeding paper or aligning covers. Semi-automated binding machines are ideal for small-scale operations that require moderate speed and flexibility.

Synonyms used: stationery production equipment and book binding machinery.

2.2 Fully Automated Notebook Making Machines

High-end models incorporate automated sheet feeding, cover pasting, cutting, punching, binding, and trimming in one integrated workflow. These systems are ideal for large-scale manufacturing units aiming for high throughput and consistent quality.

2.3 Spiral Binding and Wire-O Binding Machines

These machines are specifically designed to create spiral or wire-O bound notebooks. They include punch mechanisms, coil insertion, and cutting to length. This equipment often complements a general notebook making machine setup.

2.4 Perfect Binding Units

Perfect binding systems (glue binding) may be added to create soft-cover style notebooks or books. Though not a traditional notebook binding method, these are often part of book binding machinery for product diversification.

2.5 Cutting, Trimming, and Edge Finishing Equipment

Once binding is done, edges must often be trimmed with a page cutting and binding machine or a trimming unit. This ensures that the finished notebook has clean edges and uniform shape.

3. Advantages of Buying a Notebook Making Machine in Mangalagiri, Andhra Pradesh

If you plan to establish or upgrade your stationery production facility, locating your source of equipment near Mangalagiri can offer several advantages:

-

Local Supplier Proximity: Saves on transportation costs, reduces delivery time, and simplifies technical service and spare parts supply.

-

Regulatory Familiarity: Vendors in Andhra Pradesh will be familiar with state regulations, electricity norms, and industry compliance.

-

After-Sales Service: Local or regional manufacturers or suppliers often provide reliable maintenance, installation, and training support.

-

Customization: Close collaboration enables you to request modifications or adjustments tailored to your production needs.

-

Economic Ecosystem: Mangalagiri is well-connected by road and rail; parts and raw materials (paper, binding supplies, covers) are easily available in and around the region.

Because of these benefits, choosing a notebook making machine supplier based in or near Mangalagiri, Andhra Pradesh can strengthen your competitive advantage in the stationery market.

4. Key Specifications to Compare

When evaluating paper binding equipment or binding and trimming systems, consider these technical parameters:

-

Speed — sheets per minute or notebooks per hour. Automated machines may deliver 50–300 notebooks/hour depending on design.

-

Notebook Format — size (A4, A5, custom), page count, cover type, binding style (spiral, saddle stitch).

-

Binding Method — wire-O, comb/spiral, glue binding, stapled binding.

-

Cutting/Trimming Accuracy — millimeter tolerance on edges or deckle cutting.

-

Power Consumption — electricity phases, voltage, motor ratings.

-

Control Interface — manual levers, digital touchscreen controls, PLC-based automation.

-

Material Handling — paper feeder capacity, cover feeder, stack height.

-

Maintenance Access — ease of spare-part replacement, availability of local servicing.

-

Safety Features — guards, emergency stop buttons, compliance with Indian Bureau of Standards or state safety regulations.

By comparing these metrics across different book binding machinery models, you can estimate throughput, cost per unit, and return on investment more accurately.

5. Leading Suppliers & Manufacturers Near Mangalagiri

While direct web-search yields limited names, here are some suggested steps to identify notebook making machine suppliers servicing Mangalagiri:

-

Reach out to machinery manufacturers in Andhra Pradesh and Telangana for quotation requests.

-

Visit industrial zones or trade fairs near Vijayawada / Guntur region, which are close to Mangalagiri.

-

Ask for references from local stationery producers about their stationery production equipment vendors.

-

Request on-site demonstration of book binding machinery before purchase to verify speed and binding quality.

Once you shortlist vendors, compare quotes based on warranty, spare-parts availability, on-site installation cost, and post-sales support.

6. Cost Estimation & Return on Investment

Initial Investment

A basic semi-automatic notebook making machine might cost anywhere from INR 1 Lakh to INR 5 Lakhs depending on capacity and features. Fully automated systems may range much higher, often INR 10 Lakhs and above based on configuration.

Operational Costs

Include electricity consumption, paper waste, binding supplies (spirals, glue, covers), maintenance labor, and depreciation. Evaluate cost per notebook produced to compare with manual assembly.

Break-Even Period

Calculate the break-even point by estimating daily production volume multiplied by your unit margin less operational costs. For example, if you produce 500 notebooks per day at a margin of ₹5 per notebook, that yields gross income of ₹2,500/day. Deducting daily operational cost (e.g. electricity, material waste, maintenance) gives net profit. Divide initial capital cost by net profit per day to determine days to break even.

Scalability

Adding additional machines or upgrading to higher-speed automated versions can increase capacity if the business demand grows (e.g. supplying schools, colleges, publishing units in Andhra Pradesh or beyond).

7. Installation, Commissioning & Staff Training

A successful deployment of automated notebook machine or page cutting and binding machine requires:

-

Site preparation: ensure foundational platform, electric supply, ventilation, grounding, and floor leveling.

-

Machine delivery and alignment: vendor technicians must ensure alignment, calibration, and test-run production.

-

Operator training: staff must understand machine controls, error handling, troubleshooting, and cleaning procedures.

-

Maintenance schedule: periodic lubrication, inspection of blades, checking wear & tear on binding mechanisms, and replacement of consumable parts (e.g. coils, wire binding material).

-

Quality checks: routine inspection of margin alignment, binding tightness, trimming accuracy, and product appearance before packaging.

A well-trained staff helps maximize uptime and ensure consistent notebook quality, which enhances your brand trust in the stationery marketplace.

8. Environmental & Regulatory Considerations

When operating a notebook manufacturing setup in Andhra Pradesh:

-

Ensure compliance with state pollution control board regulations regarding noise and dust if the operation involves cutting emissions.

-

Use eco-friendly glues or adhesives if local environmental guidelines require volatile organic compound (VOC) limits.

-

Proper disposal of paper waste and recycling programs may be necessary to maintain sustainable operations.

-

Adhere to electrical safety and worker-health norms mandated under Indian labor laws and any Andhra Pradesh-specific guidelines.

Using certified binding and trimming systems with safety guards will help meet regulatory standards and reduce liability.

9. Marketing & Sales Strategy for Your Notebooks Business

Once your notebook production system is operational, you should plan effective marketing to sell your output across Andhra Pradesh and beyond. Some strategies:

-

List your notebooks on online marketplaces (e.g. Amazon India, Flipkart) under categories of school supplies.

-

Offer B2B sales to schools, coaching institutes, corporate stationery suppliers in Hyderabad, Vijayawada, and surrounding areas.

-

Highlight that your notebooks are “manufactured locally in Mangalagiri, Andhra Pradesh” — this gives trust and shorter delivery time to customers.

-

Promote custom notebook options — special covers, branding prints, sizes, bulk orders — enabled by your flexible stationery production equipment.

-

Provide sample sets to regional retailers, coaching centers, and bookshops to demonstrate quality and binding finish.

Monitoring customer feedback for binding durability, stitching or spiral tightness, and trimming finish will help you optimize adjustments in your notebook making machine or book binding machinery settings.

10. Frequently Asked Questions

Q1: How many notebooks per hour can a typical machine in Mangalagiri produce?

A semi-automatic binding machine may deliver up to 100–200 notebooks/hour, while a fully automated notebook production system can exceed 300 notebooks/hour—depending on size and binding method.

Q2: Can I convert a machine later from coil binding to perfect binding?

Many advanced page cutting and binding machines support modular add-ons for perfect binding or glue-based binding. Request modular compatibility from the vendor before purchase.

Q3: How long is the warranty and what about spare parts?

Local suppliers around Mangalagiri often provide 1-year warranty and stock common spare parts locally. Verify lead time for special components such as punching dies or motor assemblies.

Q4: Does power supply variation in Andhra Pradesh impact machine performance?

Voltage fluctuations may affect motor-driven binding and trimming systems. Ask vendors for built-in surge protection, voltage stabilizer compatibility, or backup UPS options.

Q5: Is staff training provided onsite?

Quality vendors in Andhra Pradesh typically include operator training as part of installation support. Confirm this in your quotation.

Conclusion

Investing in a high-performance notebook making machine for your stationery production business in or near Mangalagiri, Andhra Pradesh, is a strategic decision. By carefully evaluating machine type, binding method, vendor capabilities, and scalability, you can establish a robust operation capable of delivering reliable, high-quality notebooks to your customers.

Whether you choose semi-automatic or fully automated systems, spiral binding or perfect binding options, always consider local support, machine specification, operating costs, and after-sales service. With the right equipment—such as paper binding equipment or book binding machinery—you can build a sustainable and growing enterprise in the paper products sector.