Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

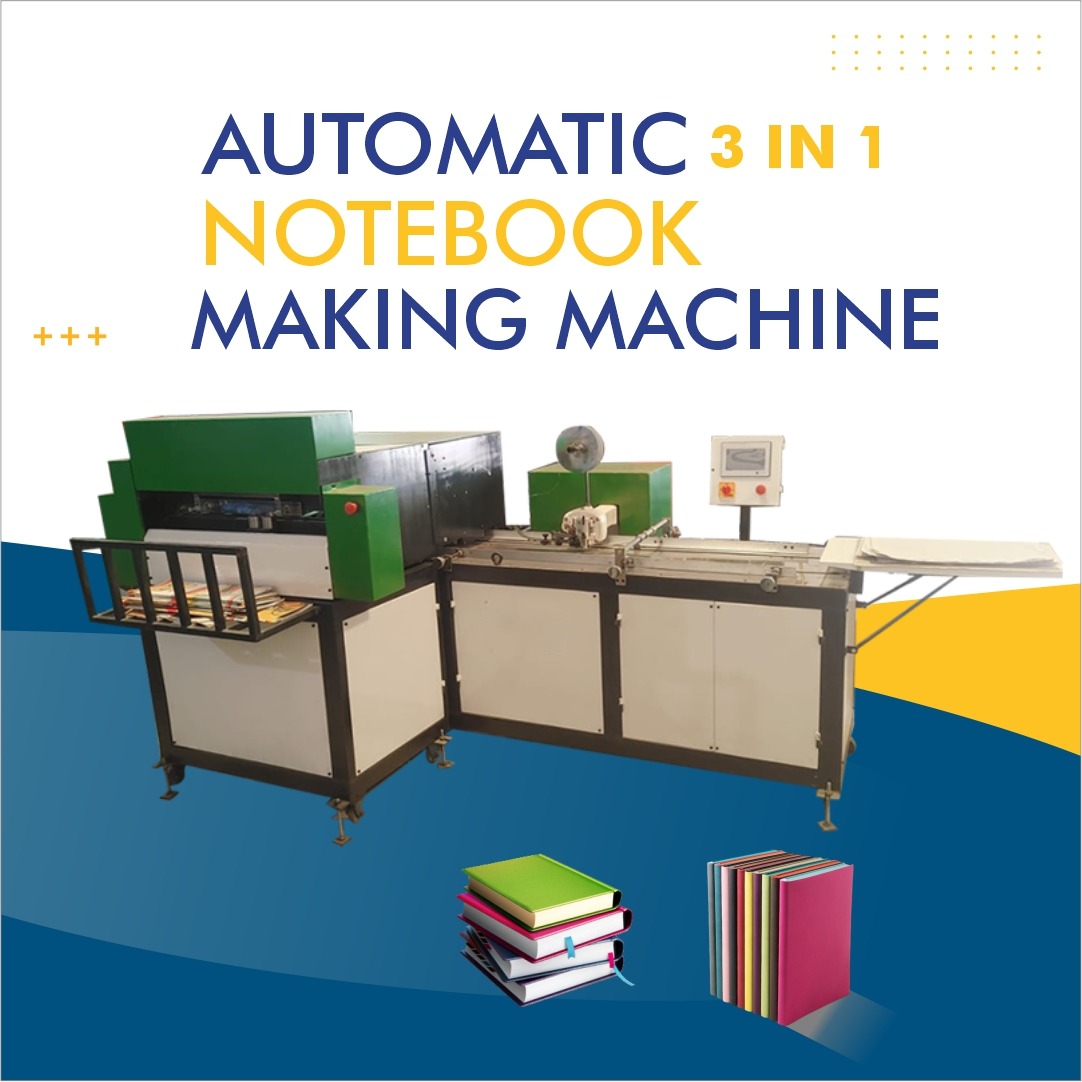

Notebook Making Machine in Madanapalle | Supplier & Manufacturer Andhra Pradesh

Notebook Making Machine in Madanapalle | Andhra Pradesh

Are you looking for a state-of-the-art notebook making machine in Madanapalle, Andhra Pradesh? Whether you run a stationery factory, a printing press, or you are expanding into notebook manufacturing for academic supplies, our facility provides cutting-edge notebook production equipment tailored to your needs. From high-speed notebook binding to precise cutting, our machines deliver excellent output and robust productivity.

In this article, we’ll examine the features, benefits, types, and applications of notebook making machines available locally in Madanapalle. We’ll also explain how investing in the right notebook manufacturing equipment can boost your productivity, reduce costs, and improve the quality of your notebooks.

Why Choose Madanapalle as Your Base for Notebook Machinery?

-

Strategic Location: Madanapalle is well-connected to regional transportation networks across Andhra Pradesh. That makes delivery of heavy machinery smoother and reduces logistics costs.

-

Local Support & Services: Sourcing your notebook binding or production equipment locally reduces downtime. Spare parts, technical support, installation and maintenance are more accessible than ordering from distant suppliers.

-

Cost-Effectiveness: Compared to metropolitan cities, sourcing machinery locally often reduces import duty, transportation surcharge, and delivery delays.

-

Community of Paper-Based Units: The region has access to skilled technicians, engineers, and supply-chain vendors for paper, raw materials, and ancillary stationery operations.

What Is a Notebook Making Machine?

A notebook making machine refers to equipment or an assembly of machines designed to produce finished notebooks from raw materials such as paper, cardboard, binding wire or glue, cover stock and finishing components. It automates multiple stages: cutting paper to size, stacking sheets, binding or stitching, trimming edges, binding the cover, and sometimes packaging.

Synonyms / Related Terms:

-

Notebook production equipment

-

Notebook manufacturing machine

-

Book binding machine

-

Printing & binding system

-

Stationery production line

These terms are often used interchangeably by buyers and in search queries.

Main Components and Features

-

Paper Cutting & Trimming Unit

-

Precision guillotine or rotary cutters

-

Adjustable dimensions for various notebook sizes (A4, A5, custom sizes)

-

Safety guards and digital control panels

-

-

Sheet Stacking & Collating

-

Automated feeders that align paper sheets in proper sequence

-

Collation units that gather cover and inner sheets

-

-

Binding / Stitching / Spiral Insertion

-

Wire-spiral binding heads or loop-wire inserters

-

Glue binding or perfect binding stations (for softcover notebooks)

-

Stapling / sewing heads for stitched notebooks

-

-

Cover Attaching System

-

Hot–melt glue applicators

-

Automatic or semi-automatic cover feeding

-

Embossing or laminating attachments (optional upgrade)

-

-

Edge Trimming / Perforating & Punching

-

Side trimming to remove excess edges

-

Perforating tools for tear-off notebooks (e.g. detachable pages)

-

Punch holes (ring binder style)

-

-

Conveyor & Delivery Output

-

Finished-product conveyor belts

-

Stacking tables or manual collection points

-

Quality inspection station to ensure finish and consistency

-

-

Control Panel & Automation

-

PLC / HMI interface for speed control

-

Safety interlocks and sensors

-

Optional automation: servo-driven alignment, automatic waste ejection

-

Types of Notebook Making Machines

-

Semi-automatic Notebook Making Machine

Suitable for small-scale manufacturers or workshops. Operator involvement needed for loading sheets, binding media, and removal. Good stepping-stone for startups. -

Fully automatic Notebook Production Line

Ideal for high-volume production. Minimal human intervention. Integrated cutting, collating, binding, trimming, and packing modules. -

Compact Desktop Binding System

Designed for small offices, schools, or local book-binding services. Lower cost, limited throughput but good for sample notebooks or short runs. -

Custom-built Machines

Tailored to specific notebook formats (e.g. custom page count, embedded pockets, special covers). Local manufacturers in Madanapalle can adapt or retrofit units to your specifications.

Applications & Use Cases

-

School-grants & Educational Suppliers offering bound notebooks for students.

-

Stationery Manufacturers producing branded notebooks for retail.

-

Local Print Shops expanding services to finished books / notebooks.

-

Corporate Branding Units needing customized notebooks with company logos or thematic covers.

-

Promotional Gift Suppliers requiring small-batch custom notebooks for events.

Benefits of Investing in a Local Notebook Making Machine

| Benefit | Explanation |

|---|---|

| Reduced Production Cost | Automating cutting, binding, and trimming reduces manual labour and wastage. |

| Faster Turnaround Time | In-house production means you don’t wait for external binders or sub-contractors. |

| Better Quality Control | You oversee the production at every stage: alignment, glue quality, finishing standards. |

| Increased Flexibility | You can change margins, cover materials, binding styles as per demand. |

| Scalability | As demand grows, you can upgrade to higher-capacity machine modules. |

Choosing the Right Machine: Key Considerations

-

Throughput & Speed

Estimate your monthly or yearly production volume (number of notebooks). Choose a machine whose speed (e.g. notebooks per minute or hour) matches your requirements with some margin for growth. -

Size & Format Flexibility

If you plan to offer multiple sizes (A4, B5, custom), choose machinery with adjustable dimensions or quick-changeover features. -

Binding Style

Decide whether you need spiral binding, staple/stitch binding, perfect glue-binding, or ring / wire-binding. Confirm that the machine supports multiple binding styles or is upgradeable. -

Automation Level

Fully-automatic setups cost more upfront but reduce per-unit labour cost and increase reliability. Semi-automatic may suit low-volume or startup operations. -

Energy Consumption & Power Requirements

Check voltage compatibility and power supply in Madanapalle (three phase, local regulatory norms). Also consider maintenance ease and spare-part availability. -

Payload Handling & Safety Standards

Compliance with statutory norms (electrical safety, machine guarding) and ease of operation for local staff. Ensure warranty, service-maintenance plan, and training are provided by the supplier. -

After-Sales Support & Spare Parts

Choose suppliers who maintain stock of cutting blades, binding heads, glue nozzles, electrical components in Andhra Pradesh region, ideally Madanapalle or nearby. -

Price & Financing Options

Compare capital cost and ROI. Some local manufacturers or distributors may offer leasing, EMI payment, or financing plans for machinery investment.

Local Supplier & Service Support in Madanapalle

When you procure a notebook making machine in Madanapalle:

-

You can schedule on-site installation by technicians familiar with local workshop infrastructure.

-

Spare parts such as cutting blades, binding wires, glue, control wiring can often be sourced from vendors in and around Chittoor / Tirupati region.

-

Training for your operators is easier to arrange when the manufacturer or supplier is nearby.

-

Routine maintenance and calibration can be scheduled periodically to ensure uptime.

Cost Estimation & ROI

The initial investment for a semi-automatic notebook binding machine may range from moderate-budget to mid-tier depending on capacity, binding style, and automation features. Fully-automatic production lines will tend to have a higher capital outlay but deliver faster payback through higher throughput and lower labour cost per notebook.

-

Calculate fixed cost (machine cost + installation + shipping to Madanapalle).

-

Estimate variable cost (electricity, labour, raw materials like paper, glue, binding wire).

-

Forecast monthly production volume: e.g. if you plan to produce 10,000 notebooks per month, estimate your revenue per notebook against production cost to compute payback period.

-

Typical payback may range from 12 to 24 months depending on sales price, market demand, and production efficiency.

Maintenance & Quality Assurance

To ensure longevity and quality of production:

-

Follow periodic preventive maintenance schedules: cleaning, lubrication, alignment checks.

-

Use recommended spare parts and consumables.

-

Calibrate binding tension and trimming alignment to avoid rejects.

-

Implement quality sampling at regular intervals (e.g. one notebook per 100 units) for consistency of cuts, binding tightness, and cover alignment.

Regulatory & Compliance Considerations

Operating heavy stationery-manufacturing equipment in Andhra Pradesh (including Madanapalle) may require adherence to:

-

Local electricity utility regulations (load-capacity, safety wiring).

-

Workplace health & safety norms for machinery operators.

-

Environmental considerations (waste paper disposal, glue fumes ventilation).

-

Business registration and industry standards for stationery / printing enterprises.

How to Order & Install in Madanapalle

-

Initial Enquiry & Specification Definition

Contact the supplier with details: desired notebook sizes, binding types, expected output, budget, and available floor-space in your premises in Madanapalle. -

Site Visit & Layout Planning

Supplier or technician may visit your facility to inspect available power supply, floor dimensions, ventilation, dust-control system, and material feed path. -

Manufacture / Customisation

Supplier prepares the machine or production line modules based on agreed specifications. Local customisations (sheet size changeover settings, binding heads, control panel languages) can be configured. -

Delivery & Installation

Heavy-machine delivery to your premises near Madanapalle involves local transport, crane or lift-support if required, base-foundation levelling, electrical & pneumatic hook-ups, safety testing. -

Operator Training & Trial Run

Once installed, supplier technicians provide training to your staff on machine operation, safety protocols, maintenance schedule, and first-run quality check. -

After-Sales & Support

Ensure you receive operation manual, spare parts list, warranty certificate, and contact details for service support in Andhra Pradesh.

Conclusion

If you are planning to establish or expand a notebook manufacturing business in Madanapalle, Andhra Pradesh, investing in a high-quality notebook making machine can transform your output, reduce wastage, and improve the speed and quality of delivery. Evaluate your production volume, binding style, and budget to select between semi-automatic, fully automatic or customised notebook production equipment.

To get started, request a quote from our team with your specifications (paper size, binding type, monthly output), arrange a site visit, and let us help design a production line tailored to your needs in Madanapalle.