Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Kandukur | Andhra Pradesh Notebook Production

Notebook Making Machine in Kandukur | Andhra Pradesh

If you are planning to establish or expand a notebook manufacturing unit in Kandukur, Andhra Pradesh, investing in a reliable and efficient notebook making machine is crucial. Whether you are starting small or scaling up operations, choosing the right machinery and setup can dramatically impact productivity, cost-efficiency, and product quality.

In this guide, we’ll explore everything you should know about notebook making machine options, technical aspects, benefits, site planning in Kandukur, cost considerations, and local opportunities in Andhra Pradesh.

2. Importance of Choosing the Right Notebook Making Machine

-

Quality & consistency: Machines that stitch, fold, trim, and square ensure each notebook is uniform in appearance and durable in use.

-

Production capacity: Based on demand (local schools, stationery shops, bulk orders), you may need manual, semi-automatic or fully automatic lines.

-

Automation level: A fully automatic notebook manufacturing machine reduces labour, increases speed, and lowers error; semi-automatic or manual types cost less initially but require more human input.

-

Scalability & future growth: Selecting modular equipment means you can add folding, trimming, edge squaring units later.

-

Maintenance & sourcing spare parts: Machines closer to you (or suppliers able to serve Andhra Pradesh / Kandukur region) reduce downtime.

3. Types of Notebook Making Machines & Their Features

Here are some categories with real-world references:

-

Manual / Semi-Automatic Notebook Making Machines

-

Entry-level machines suitable for lower production volumes. asvrengineering.com+1

-

Useful if you are just starting or testing the market before investing heavily.

-

-

Semi-Automatic Notebook Production Line

-

Includes stamping, folding, stitching by wire, trimming and edge squaring modules. smallbusinessolution.com+1

-

Moderate investment, moderate labour dependency.

-

-

Fully Automatic Notebook Making Machine

-

High capacity; stitching, folding, trimming, edge-squaring integrated in one line. sujatamachines.in+2endurancemachinery.com+2

-

Capable of producing 1,000–2,000 or more notebooks per hour depending on model. National Industries+1

-

Efficient for medium or large-scale production with less manual intervention.

-

-

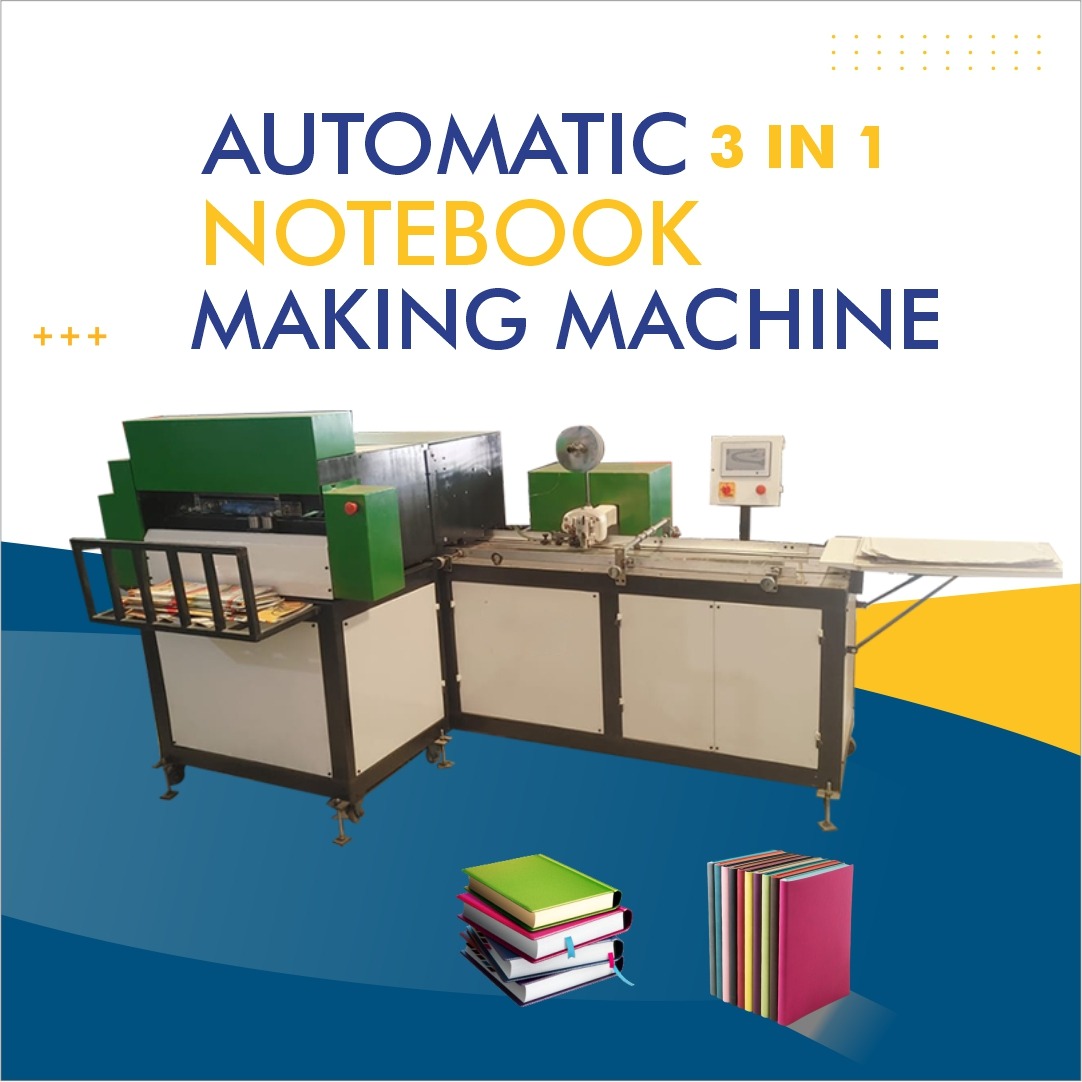

3-in-1 or All-in-One Notebook Making Machine

-

These combine functions like stitching, folding and edge squaring in a compact integrated unit. sujatamachines.in+1

-

Useful if you want a compact footprint with multi-stage automation.

-

Common Specifications to Compare

-

Production capacity (books per hour / per shift)

-

Maximum book thickness (number of pages or mm)

-

Dimensions & size range (A4, B5, custom sizes)

-

Power requirement & voltage (often three-phase / industrial supply)

-

Automation grade & PLC / servo control

-

Weight, footprint & optional features (sensors, controls)

4. Setting up Notebook Manufacturing in Kandukur, Andhra Pradesh

Why Kandukur?

-

Kandukur is a town in the Prakasam district of Andhra Pradesh. It is well-positioned in the coastal-inland belt, accessible to raw material sources and market networks.

-

Proximity to regional hubs (cities like Ongole, Nellore, or larger transport corridors) may ease logistics and supply chain for paper, binding materials, and finished goods distribution.

-

Andhra Pradesh’s industrial policy may provide advantages such as lower land cost (compared to major cities), local labour availability, and potential state schemes for manufacturing units.

Site Requirements & Utilities

-

Ensure stable electricity supply (three-phase power) for running automatic or semi-automatic equipment.

-

Adequate workshop space for machine footprint + raw material storage + finished goods handling.

-

Proper ventilation, flooring, dust control (paper dust is typical in stationery manufacturing).

-

Sewage & water disposal norms depending on local municipality / Gram Panchayat / urban planning authority in Kandukur.

-

Access to roads for inbound raw-paper delivery and outbound transportation.

Labour & Skills

-

Hire or train operators familiar with binding, trimming, machine operation.

-

Maintenance staff for mechanical / electrical upkeep of notebook making machinery.

-

Quality control personnel to inspect finished notebooks for alignment, binding strength, cutting quality.

5. Cost Components & Financial Planning

Machinery Cost

-

Manual / semi-automatic machines may cost lower initially, but capacity is modest. smallbusinessolution.com

-

Fully automatic machines cost significantly more (several lakhs of rupees), but deliver higher throughput and lower labour cost per unit. National Industries+1

-

Installation, foundation works, safety guards, conveyors & alignment add to base machine price.

Raw Material Cost

-

Paper sheets, ruled paper, cover boards, binding wire / staples, glue, thread (if thread stitched), laminates for cover (optional).

-

Bulk purchasing of raw paper may reduce per-unit cost, but requires space and capital outlay.

Operating Cost

-

Electricity cost (three-phase motors, compressors if required in edge squaring or folding units).

-

Labour wages for operators & support staff.

-

Maintenance (periodic lubrication, repair, spare parts).

-

Packaging material and finishing touches (wrapping / plastic sleeves etc).

Revenue & Profitability Perspective

-

Determine your selling price per notebook based on page count, cover finish, binding quality and market rate in Andhra Pradesh or neighbouring districts.

-

Estimate production capacity (e.g. number of notebooks per day * working days per month).

-

Subtract total cost (raw materials + labour + utilities + depreciation & maintenance) from revenue to find profit margin.

-

Consider time-to-break-even for your investment in the machine(s) and infrastructure.

6. Marketing & Sales Strategy

-

Target local schools, coaching centres, stationery shops in Kandukur, nearby towns (Ongole, Nellore).

-

Offer customization options (custom cover design, ruled / plain pages, different sizes such as A4, A5).

-

Emphasize quality bound edges (edge squaring, uniform trimming), durability (strong binding), turnaround time (fast delivery).

-

Online presence (website, local business directories) highlighting “Notebook Making Machine production in Kandukur, Andhra Pradesh”. Use your keywords in page titles, service pages.

-

Create sample notebooks to showcase binding quality, cover finish and deliver to prospective clients to build trust.

7. Benefits & Challenges

Benefits

-

Local manufacturing in Kandukur reduces freight cost compared to importing finished notebooks.

-

Ability to supply bulk orders for schools & institutions near you.

-

Control over quality, design flexibility, and faster response time for custom orders.

-

Potential to expand into other stationery items (registers, drawing books, diaries) using similar binding & trimming equipment.

Challenges

-

Initial investment cost for high-end equipment.

-

Maintaining continuous demand to ensure full utilisation of machine capacity.

-

Managing downtime or maintenance of critical components of automated machinery.

-

Meeting regulatory / safety compliance (fire safety, electrical clearances, local municipal licences in Andhra Pradesh).

8. Synonyms & Keyword Usage

Throughout your content and web pages, you can use the following variations to ensure better search coverage:

-

Notebook Making Machine

-

Notebook Manufacturing Machine

-

Automatic Notebook Machine

-

Semi Automatic Notebook Maker

-

Exercise Notebook Production Line

-

Binding & Stitching Equipment

-

Notebook Production Machine

-

Copy/Notebook Binder Machine

Use them in headings, sub-headings, alt text for images, meta tags, and within content (but avoid keyword stuffing).

9. Action Plan – Steps to Launch

| Step | Description |

|---|---|

| 1 | Conduct a site survey in/around Kandukur to shortlist workshop location |

| 2 | Choose the type of machine (manual / semi / fully automatic) based on your target capacity & budget |

| 3 | Source quotations from reputable machine manufacturers & check if they can service in Andhra Pradesh |

| 4 | Procure necessary approvals / registration for your manufacturing unit in Andhra Pradesh (local licenses, GST registration etc.) |

| 5 | Install & calibrate the machinery; recruit / train staff for operation & maintenance |

| 6 | Run pilot production; test quality; refine your process flow |

| 7 | Begin marketing to local schools, institutions & retailers; build relationships for repeat orders |

| 8 | Monitor productivity, yield, wastage, and gradually expand capacity or diversify into related stationery items |

10. Conclusion

Investing in a notebook making machine in Kandukur, Andhra Pradesh offers you the opportunity to build or expand a stationery manufacturing business with local access, customization ability, and control over quality. By selecting the right equipment (manual, semi-automatic, or fully automatic) and planning your site, operations, and marketing carefully, you can build a sustainable and profitable venture serving regional demand as well as broader markets.