Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

High-Quality Notebook Making Machine in Guntur | Andhra Pradesh Manufacturer

Notebook Making Machine in Guntur | Andhra Pradesh

If you are planning to start or scale up a notebook manufacturing business in or around Guntur, Andhra Pradesh, investing in the right notebook making machine can make a significant difference. Whether you need a manual setup for small runs, a semi-automatic line for medium-scale production, or a fully automatic notebook production machine for high output, we offer expert advice, supply and after-sales support in and around Guntur.

In this article, you will learn:

-

Key features to look for in a notebook making machine

-

Types of notebook manufacturing machines available in India

-

Benefits of locating your notebook production near Guntur

-

How to select the right machine spec & capacity

-

Common technical terms & maintenance tips

-

Why buying from a local supplier adds value

We use several synonyms for notebook making machine through this page: notebook manufacturing machine, paper binding equipment, notebook production machine, binding machinery, notebook making equipment.

Why Guntur, Andhra Pradesh is a Good Location for Notebook Manufacturing

-

Strategic Location

Guntur lies in coastal Andhra Pradesh with good road connectivity to highways, railways and proximity to Chennai and ports. Locating your notebook production plant here can reduce logistics costs for raw materials (paper, board, binding materials) and finished goods distribution. -

Access to Skilled Workforce

With nearby towns and educational institutions, you can hire workers familiar with light industrial operations, machine operation, binding processes, finishing and quality control. -

Growing Demand & Market Access

Andhra Pradesh has thriving school and stationery markets. With schools, coaching centres, offices, and retail distribution across the state, having production near Guntur allows quicker turn-around for domestic buyers. -

Availability of Support Services

Suppliers of printing accessories, paper, adhesives, binding wire, and maintenance service providers are easier to coordinate near an industrial town like Guntur. -

Cost Advantage

Compared to metro cities, operating costs (labor, power, land/warehouse rental) may be lower, improving your return on investment for a notebook making machine setup.

Because of these factors, sourcing your notebook production machine locally or regionally makes economic sense if you plan to serve Andhra Pradesh and nearby states.

Types of Notebook Making Machines

When evaluating notebook manufacturing machine options, you’ll typically see these categories:

-

Manual Notebook Making Machine

Ideal for startup or small-scale production. Manual binding, cutting, folding, stitching processes require more human intervention. Some models (e.g. SBS NB-01 series) offer full manual setup with capacity around 3,000 notebooks/day. sbsmachine.com -

Semi-Automatic Notebook Making Machine

A hybrid line where certain operations (cutting, folding, stitching) are automated, but others need manual feed or supervision. Useful for medium-scale businesses aiming for higher productivity with moderate investment. asveng.com+1 -

Automatic or Fully Automatic Notebook Making Machine

These integrate processes like stitching, folding, edge-squaring, cutting and may include PLC-control, servo motors, high speed throughput. For example, an automatic notebook making machine with multi-head wire binding, folding and edge-squaring can deliver up to 800 books per hour per some models. endurancemachinery.com -

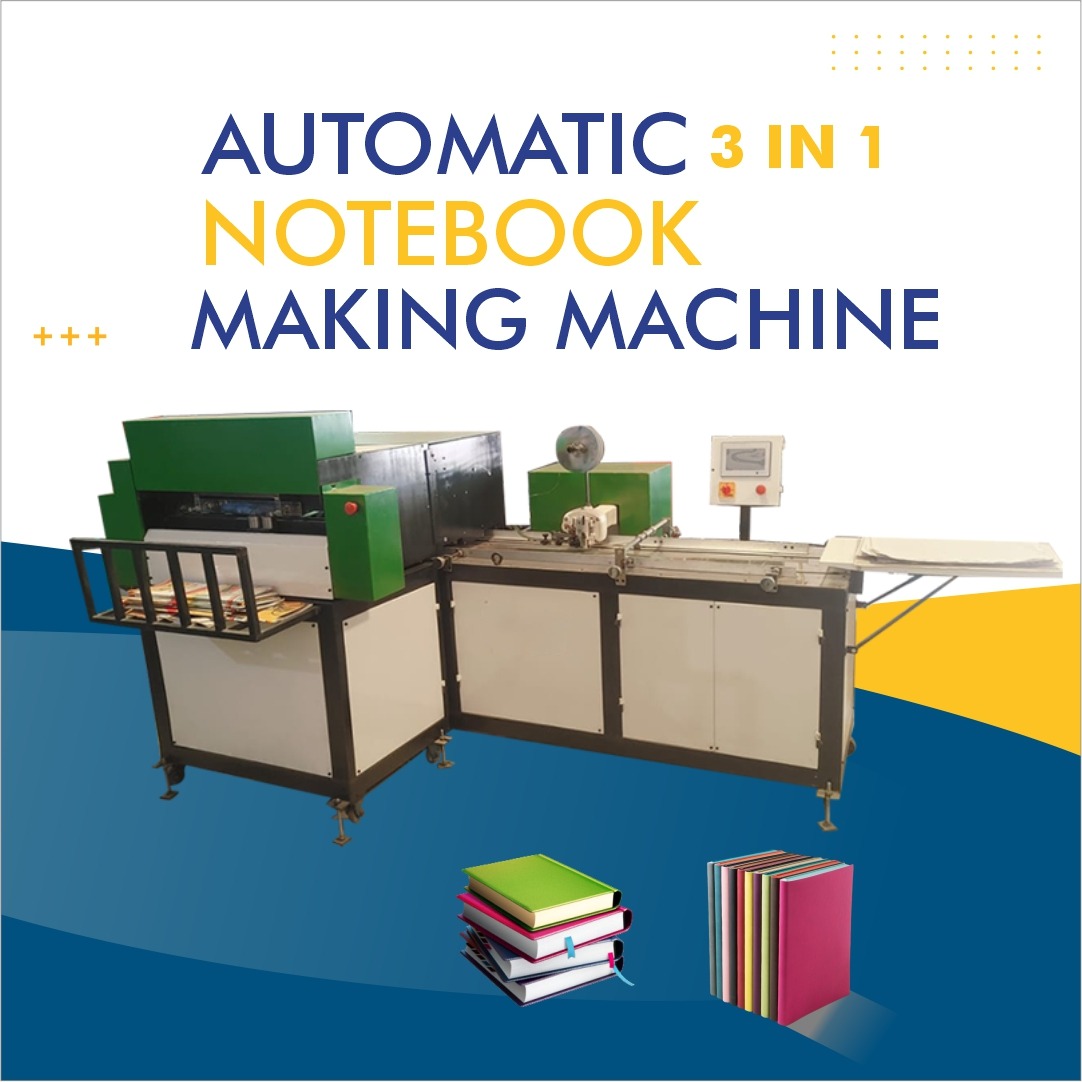

Integrated Notebook Production Machine / Line (3-in-1 or multi-function)

Some machines combine cutting, stitching, folding and trimming in one line. Useful if you want a compact footprint and minimal manual transfer between operations. namibind.com+1

Each type suits different scales of operations. If you plan to manufacture thousands of notebooks every day, you may require an automatic notebook production machine. If you serve local orders on modest scale, manual or semi-automatic may suffice.

Key Features & Specifications to Consider

When evaluating a notebook production machine for your facility in Guntur, weigh these factors:

| Specification | What to Check | Importance |

|---|---|---|

| Production Capacity | notebooks per hour / per day | Ensure throughput meets your demand targets |

| Automation Grade | manual / semi-automatic / automatic | Higher automation reduces labor but costs more |

| Binding Type | stitched (wire / pin), glue binding, punched binding | Decide based on finish and product type |

| Size & Dimensions | max/min notebook width, thickness, length | Must support the sizes you plan to produce |

| Power Requirements | voltage phase, motor power (kW or HP) | Ensure compatibility with your power supply |

| Control System | PLC control, servo motors, programmable settings | Higher precision, easier changeover between sizes |

| Material Quality | steel frame, precision rollers, safety features | Durability and longevity in Indian workshop conditions |

| Maintenance Requirements | spare parts, ease of service locally | Consider proximity to technical support or supplier |

For example, one automatic notebook making machine from a manufacturer features: multi-head wire booking stitching, folding, edge-squaring and PLC based control. It supports notebook lengths from 10" to 30", speeds up to 800 books/hour, and uses servo-based precision. endurancemachinery.com

Another semi-automatic machine delivers capacity of 3,000–5,000 pieces per day with moderate power rating (e.g. 3 kW to 5 kW). namibind.com

Manual machines may require more physical effort but cost significantly less for setup and initial capex. sbsmachine.com

Choosing the Right Machine for Your Business Plan

To select the ideal binding machinery for your scenario, follow these steps:

-

Estimate Demand / Output Target

Project how many notebooks you plan to manufacture per day or per month. For example, 2,000 units/day vs 10,000 units/day will drive vastly different machine capacity and choice of automation. -

Decide Level of Automation

-

Manual for low-volume or pilot runs

-

Semi-automatic for mid-volume scaling

-

Fully automatic for commercial high-volume production

-

-

Specify Product Size & Format

Will you produce school notebooks, exercise books, custom sizes? Confirm maximum thickness, dimension tolerances your machine must support. -

Budget vs ROI Analysis

Fully automatic machines cost more up front, but reduce labor cost and time per unit. Compute payback period vs manual/semi-auto alternatives. -

Space, Power & Infrastructure Considerations in Guntur

-

Floor area needed for the machine line and raw material storage

-

Electrical supply (voltage & phase) available in your workshop

-

Ceiling height & clearance for machine dimensions

-

-

After-Sales & Maintenance Support

Choose suppliers or manufacturers who can service the machine locally or regionally. Availability of spare parts, technical staff in Andhra Pradesh or nearby will reduce downtime. -

Compliance & Quality Standards

Ensure machine meets safety norms, electrical standards, and produces notebooks with consistent finish (edge-squaring, binding strength, cover alignment).

Benefits of Investing in a Quality Notebook Making Machine

-

Consistency & Quality: Automated stitching, folding, and trimming ensures uniform product quality across batches.

-

Increased Throughput: Automatic or semi-automatic notebook production machine can dramatically increase your output capacity compared to purely manual methods.

-

Labor Efficiency: Reduced manual workload, lower error rates, and less rework.

-

Scalability: Ability to upgrade product types or sizes with programmable settings or modular attachments.

-

Competitive Edge: Faster turnaround times result in ability to fulfill bulk orders from schools, institutions, or corporate clients.

-

Cost Savings in Long Run: Although initial investment is higher, amortised over volume the cost per notebook drops significantly with high-efficiency binding machinery.

Typical Cost & Pricing Range in India

While prices vary depending on features, capacity, brand and level of automation, here are sample ranges observed in the market:

-

Manual notebook making machine: lower-cost entry models may start in lakhs of rupees (e.g. ₹1.9 lakh for a manual machine set) sbsmachine.com

-

Semi-automatic notebook making machine sets may cost several lakhs depending on daily capacity (e.g. 5000–6000 pieces/day models) namibind.com

-

Fully automatic notebook making machine models may cost significantly more (especially high-speed, PLC-controlled models). endurancemachinery.com+1

These figures may also vary depending on shipping, installation, customization, and local taxes in Andhra Pradesh.

Setup Tips & Maintenance Best Practices

To ensure smooth long-term operation of your notebook manufacturing machine:

-

Training for Operators: Ensure your machine operators are properly trained in setup, troubleshooting and safety procedures.

-

Routine Maintenance Schedule: Lubrication, alignment checks, tightening of fasteners, inspection of binding heads or cutters.

-

Quality Checks: Periodically inspect finished notebooks for stitch integrity, edge alignment, cover warp, to avoid customer complaints.

-

Spare Parts Inventory: Keep critical spares such as binding pins, blades, belts or motors locally, to minimize downtime.

-

Power Fluctuation Protection: In some parts of Andhra Pradesh, voltage fluctuations may occur; using stabilizers or surge protectors helps protect the electronics in automatic machines.

-

Incremental Scaling: If demand grows, plan for adding another line or upgrading to a more automated notebook production machine without major rework of facility layout.

Why Choose a Local Supplier / Manufacturer near Guntur

Partnering with a notebook making equipment supplier or manufacturer close to Guntur has distinct advantages:

-

Faster site visit and assessment of your facility before purchase.

-

On-site installation & commissioning support without long travel time.

-

Local spare parts availability and faster service turnaround.

-

Better understanding of regional norms, labour availability, and local regulations.

-

Reduced freight or transport cost for bulky machine components.

A supplier offering notebook making equipment or binding machinery who can deliver and install in or near Guntur can help you avoid typical delays that arise when importing or sourcing equipment from distant states.

Conclusion

If you are looking for a reliable, high-performance notebook making machine for your production unit in Guntur, Andhra Pradesh, you must evaluate carefully the automation level, capacity, cost, maintenance support, and compatibility with your facility.

By choosing the right notebook manufacturing machine, you can optimize your production workflow, ensure consistent quality, scale effectively, and maintain strong profitability.

If you want help comparing models, obtaining quotations, or assessing installation requirements near Guntur, feel free to share your specifications (daily output, notebook size, budget). I can help you shortlist suitable machines and guide you further.